Connector assembly with variable axial assist

A connector and axis technology, applied in the field of electrical connector components, can solve problems such as reducing peak mating force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

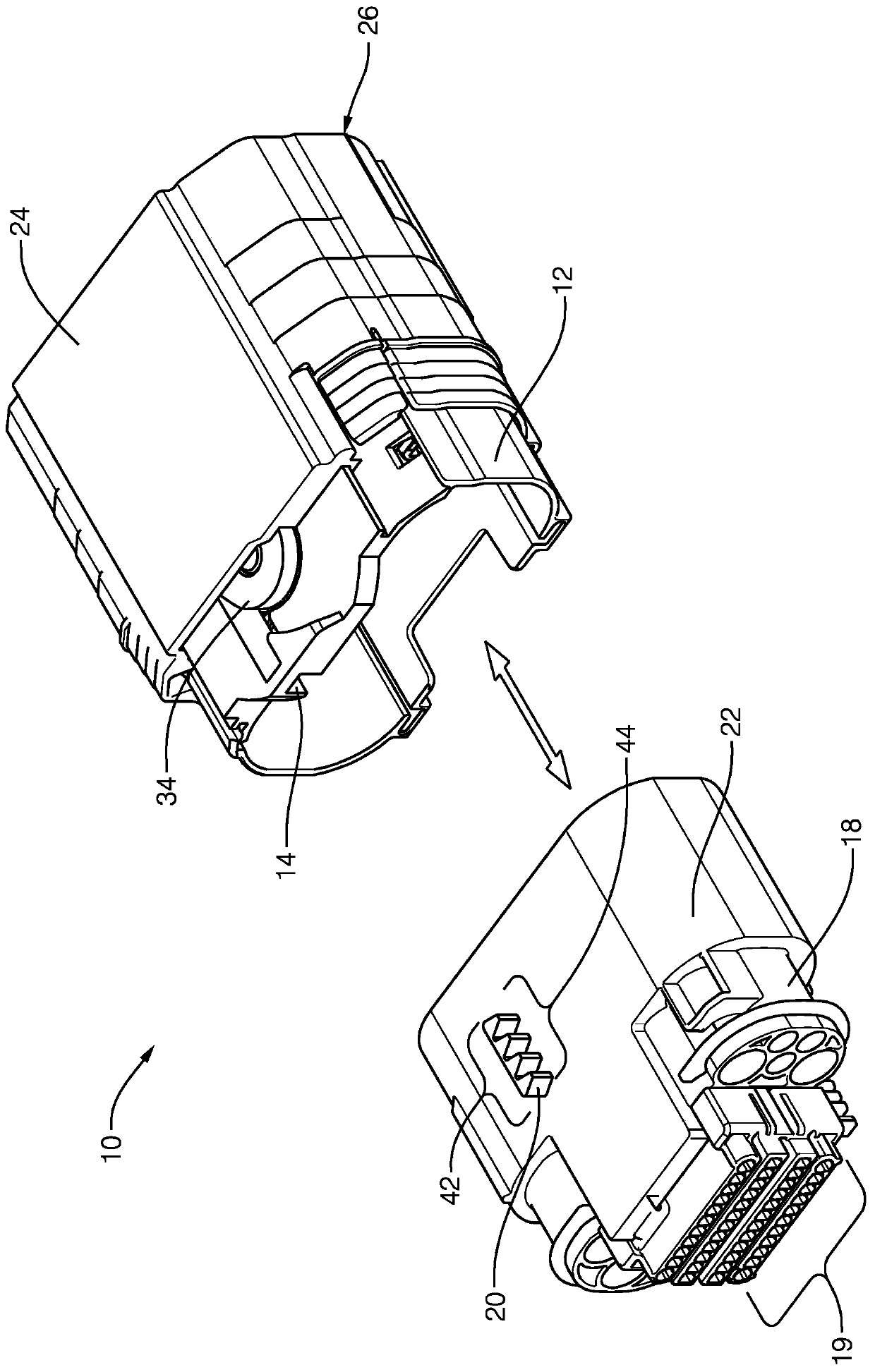

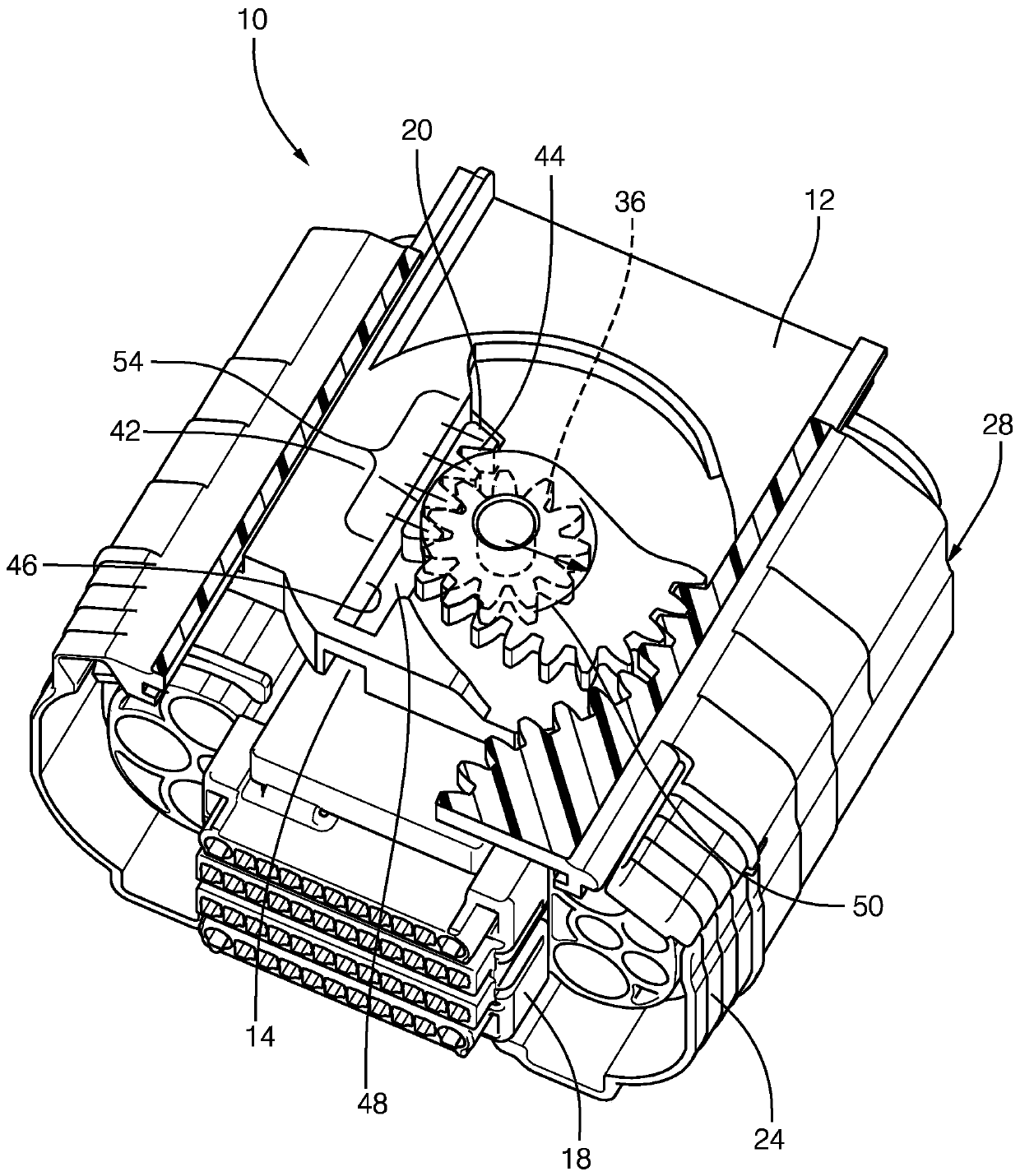

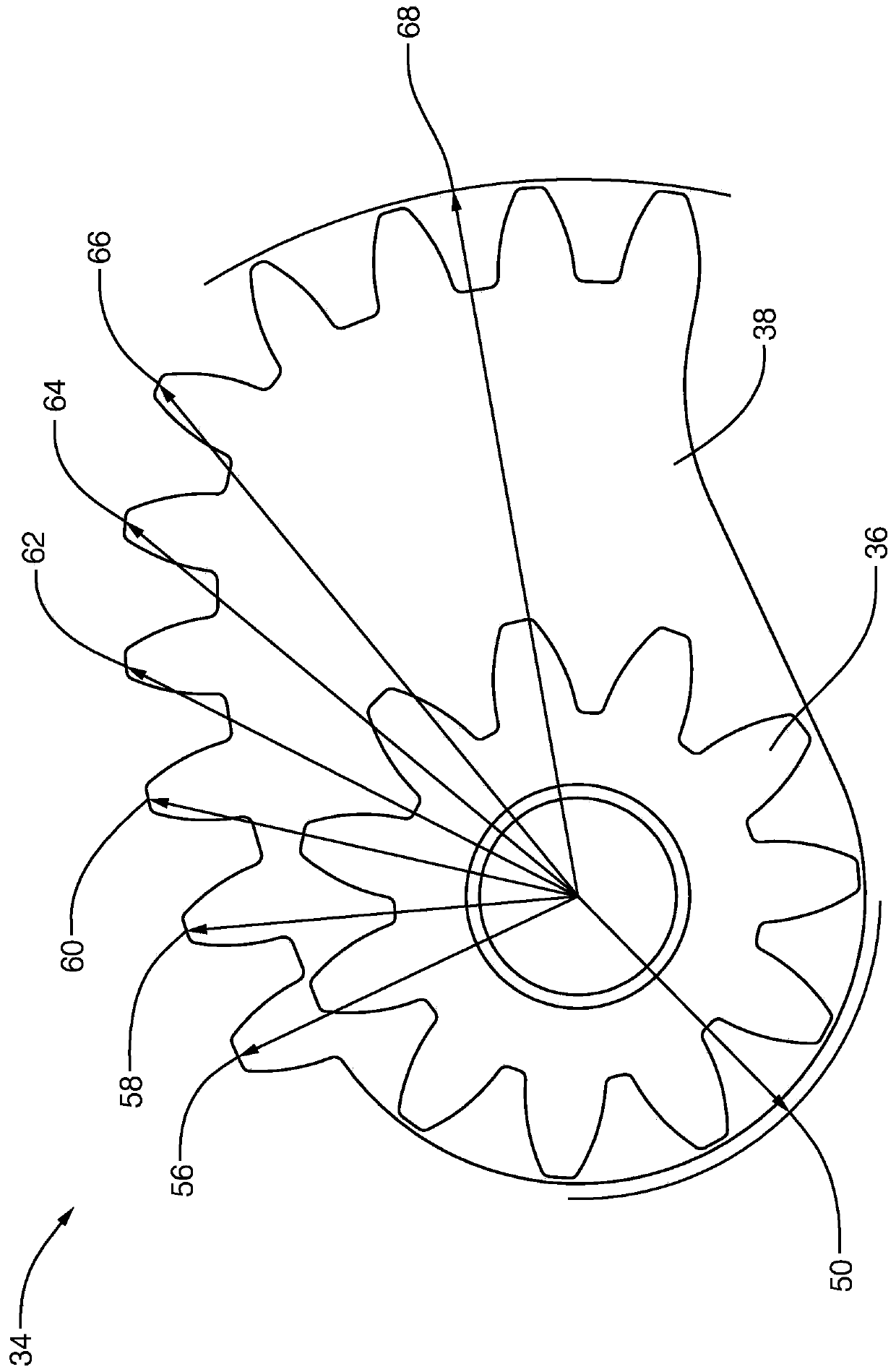

[0028] figure 1 A non-limiting example of a connector 10 is shown that includes a first housing 12 defining a guide slot 14 . The first housing 12 may have a plurality of electrical terminals 16 (not shown) attached to a wiring harness (not shown) that is part of a cable or other electrical component. The first housing 12 may also include wire seals and strain relief for the wires (not shown).

[0029] The connector 10 also includes a second housing 18 configured to mate with the first housing 12 . The second housing 18 may also have a plurality of corresponding mating electrical terminals 19 configured to mate with the electrical terminals 16 of the first housing 12 and to be attached to the wiring harness, said A harness is part of a cable or other electrical component (not shown). The second housing 18 may also include wire seals and strain relief for the wires, as well as a perimeter seal (not shown) for sealing with the first housing 12 . The second housing 18 include...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap