Compensation nut for automobile

A technology of nuts and automobiles, applied in the direction of nuts, threaded fasteners, thin plate connections, etc., can solve problems such as limited length, and achieve the effect of wide application range and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

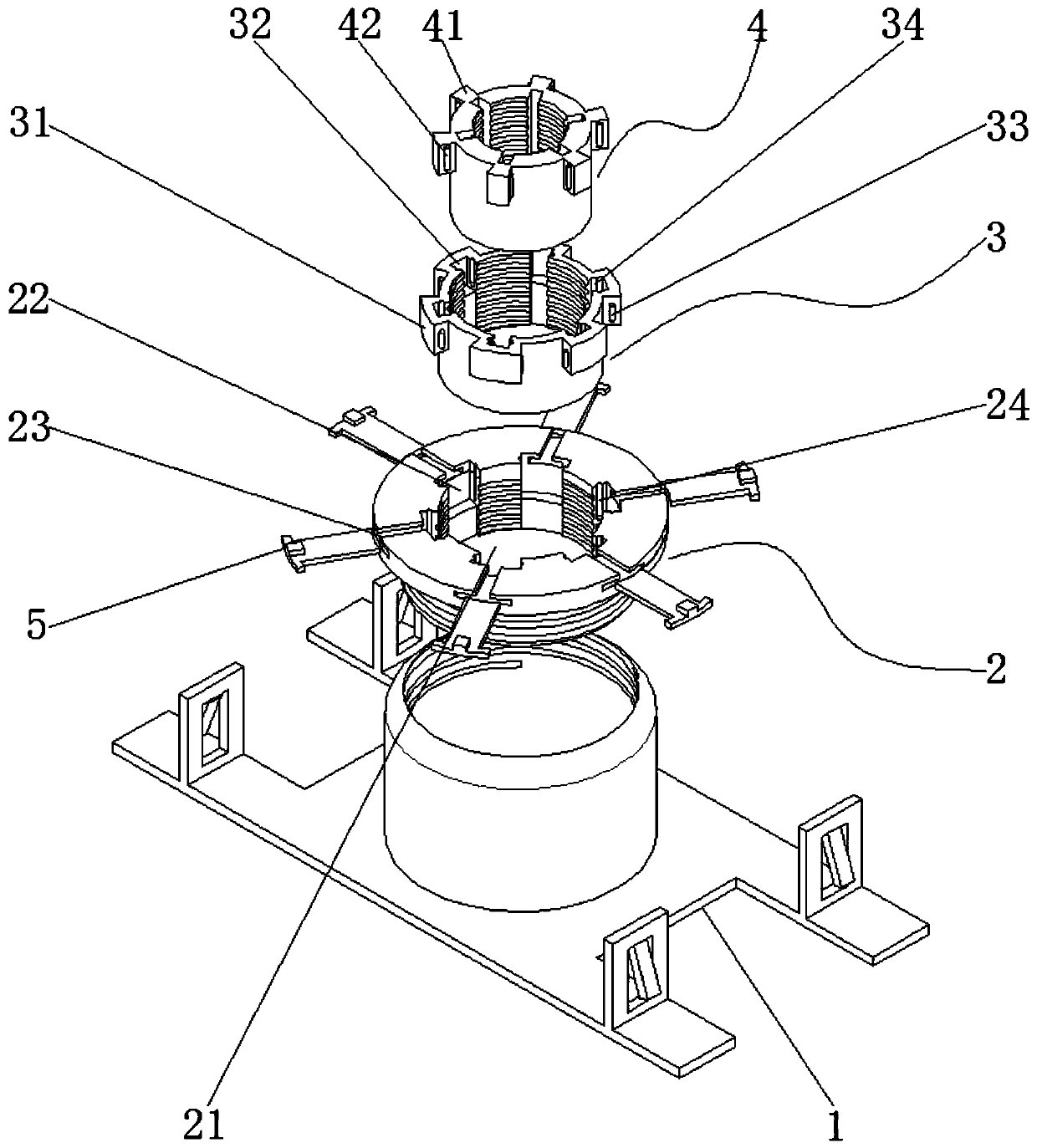

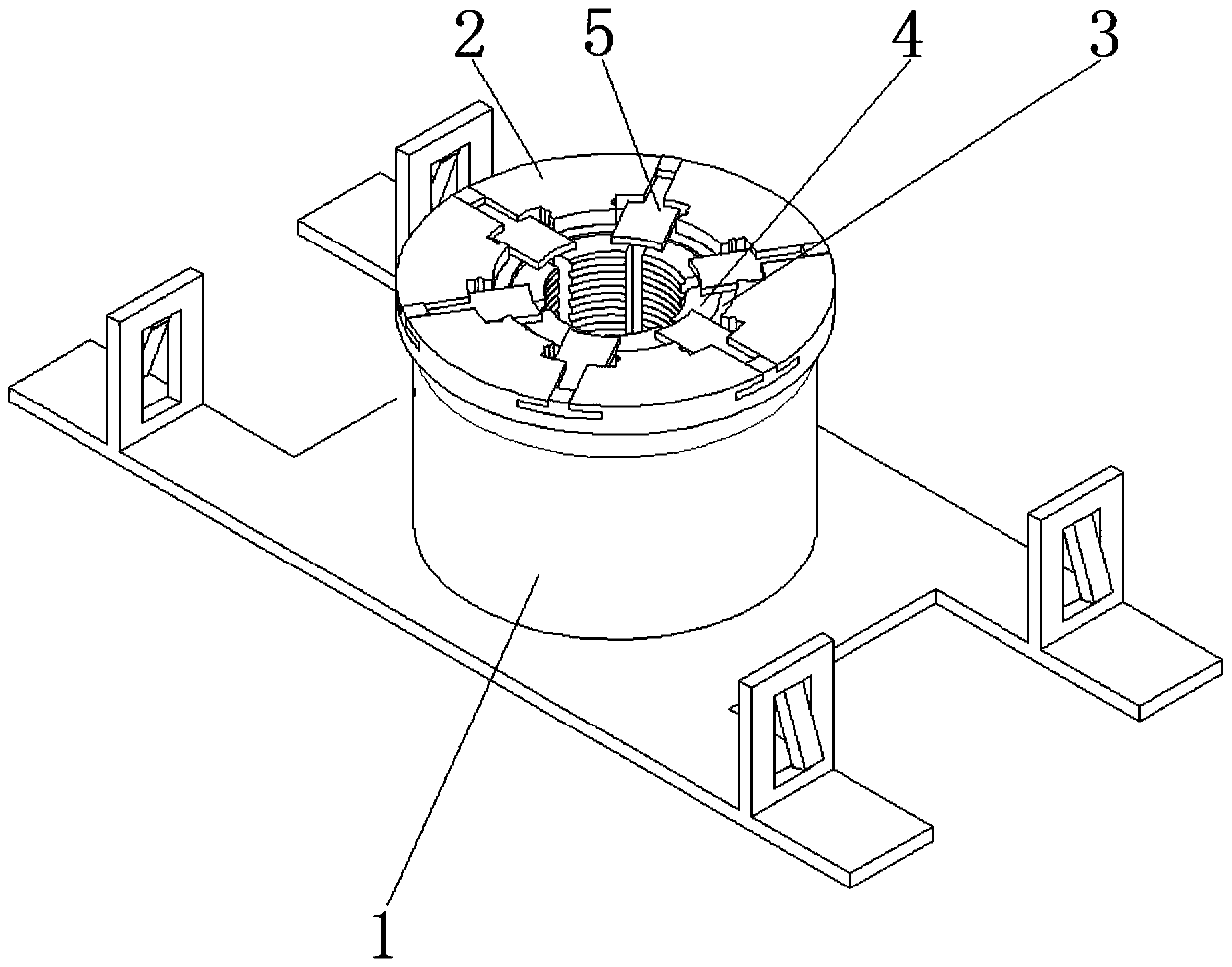

Image

Examples

Embodiment 1

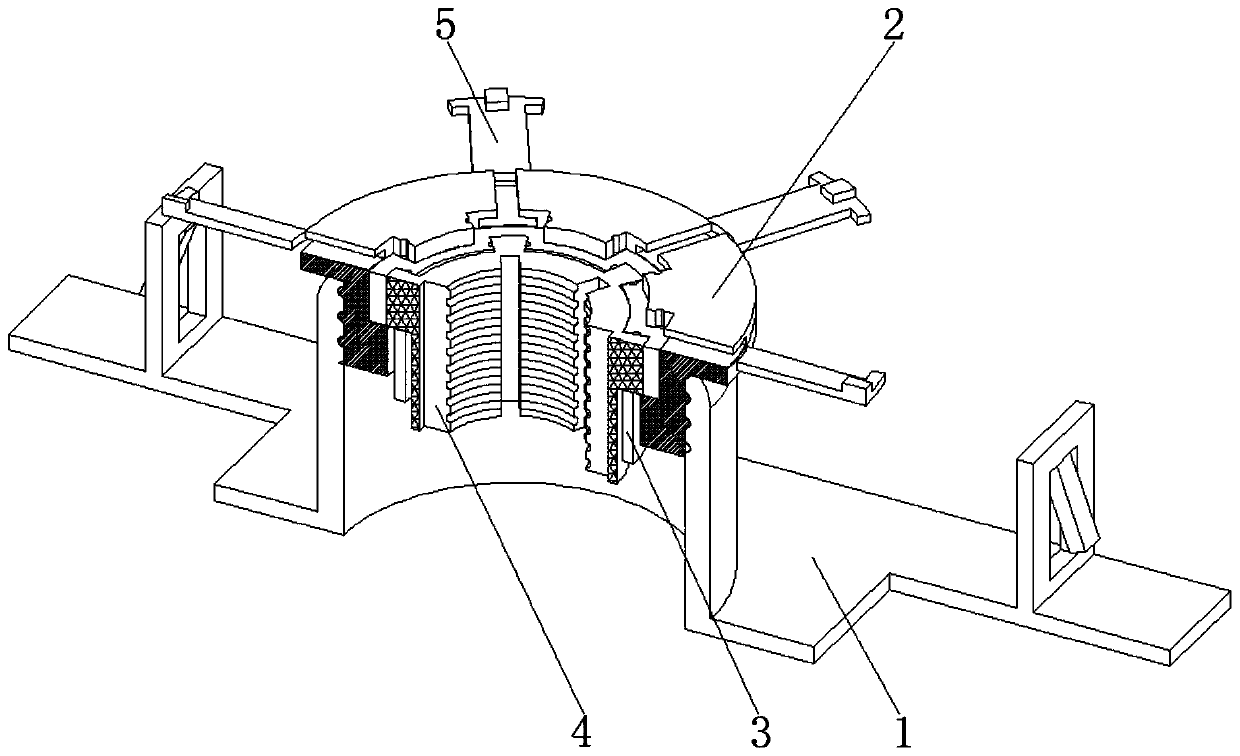

[0035] Embodiment one, as Figure 7 As shown: the diameter of the top part 2 on the compensating nut is 12mm, the inner diameter of the bushing nut 3 is 10mm, the bushing nut 3 is sleeved in the top part 2, and then the limit piece 6 is inserted into the limit groove 23, Fix the bushing nut 3 to the top part 2. The compensating nut is then capable of threading a helix with a diameter of 10 mm.

[0036] Embodiment one, as Figure 8 Shown: the diameter of the top part 2 on the compensating nut is 12mm, the inner diameter of the bushing nut 3 is 10mm, and the inner diameter of the nut 4 is 8mm, put the bushing nut 3 in the top part 2, and put the nut 4 in The bushing nut 3 is fixed by the stopper 6, and the compensating nut can be threaded to a bolt with a diameter of 8 mm.

[0037] Working principle: When in use, the top part 2 is fixed on the base 1 through a single tightening operation, the protrusion-31 of the bushing nut 3 is aligned with the groove-22, the bushing nut 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com