Liquid state concentration trace change measuring device and measuring method thereof

A technology of measuring device and measuring method, which is applied in the direction of measuring device, specific gravity measurement, and material analysis by measuring buoyancy, etc. It can solve problems such as low production efficiency, difficulty in determining the concentration of nitrate salt, difficulty in controlling and stabilizing product quality, and achieve product quality. Guaranteed, easy-to-measure effect of slight changes in nitrate concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

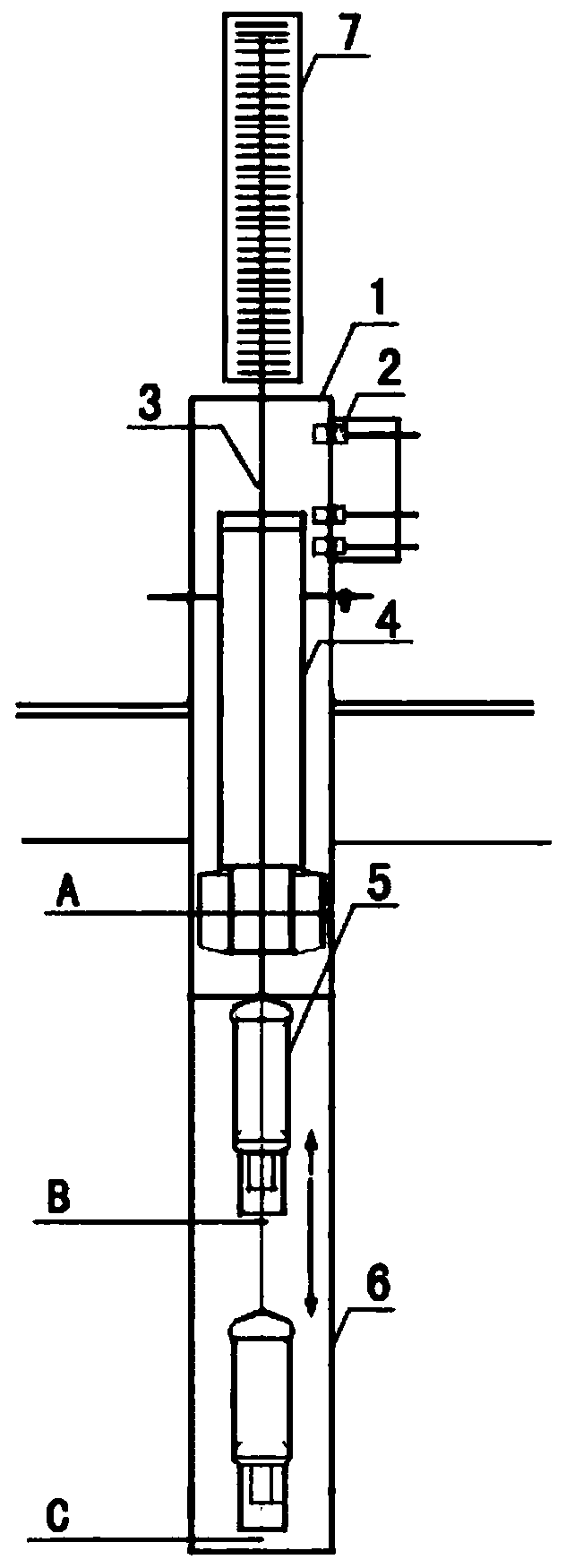

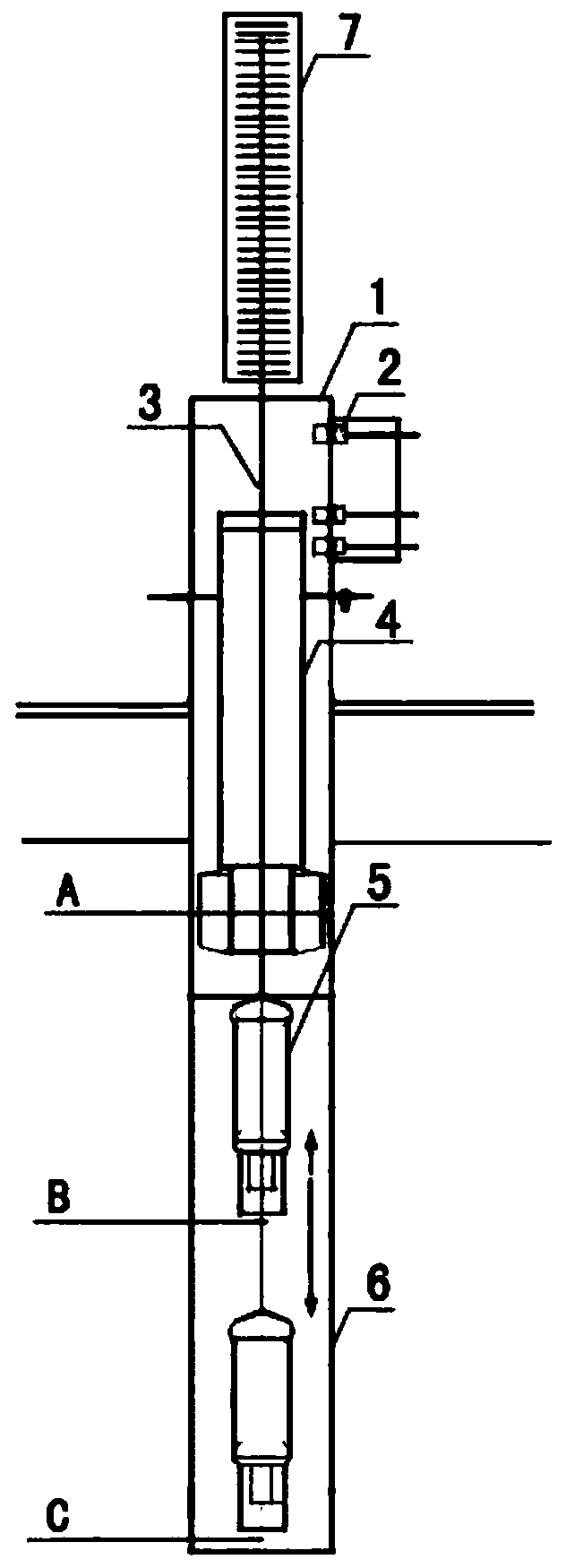

[0027] refer to figure 1 , the liquid concentration micro-change measurement device involved in the present embodiment includes a steady flow cylinder 6, a number of liquid level detection probes 2 are arranged on the upper side wall of the steady flow cylinder 6, and a liquid level is provided in the inner cavity of the steady flow cylinder 6. Float 4, the liquid level float 4 is provided with a central axis through hole to pass through the buoy pole 3, the upper end of the buoy pole 3 passes through the top cover 1 of the steady flow cylinder 6 to connect the concentration scale 7, and the lower end surface connects to the hollow The buoy 5 forms a buoyancy type marking structure; the weight of the hollow buoy 5 is proportional to the volume of the hollow buoy 5, and the buoy pole 3 is fitted and slidably connected with the central axis through hole in the steady flow cylinder 6 to form a free rise or The descending sliding connection structure drives the slight rise or fall...

specific Embodiment 2

[0056] The feature of this specific embodiment 2 is: the buoy pole 3 is a hollow stainless steel tube with a diameter of 6mm, 7mm, 7mm, 8mm, 9mm or 10mm. All the other are with specific embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap