A Method for Determining the Runaway Speed of an Inclined-Axis Pump at Different Blade Angles

A technology of blade angle and runaway speed, applied in instrumentation, design optimization/simulation, calculation, etc., can solve problems such as time-consuming and complex calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

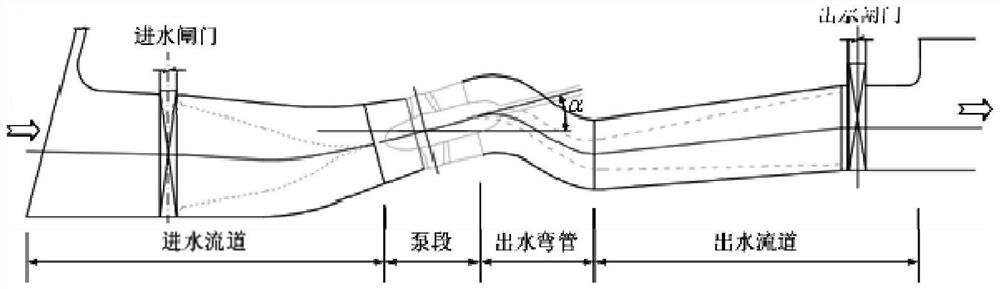

[0034] like figure 1 As shown, the inclined axis pumping station is mainly composed of water inlet flow channel, pump section, water outlet elbow and water outlet flow channel. Water enters from the left side and flows out from the right side. In this embodiment, the inclination angle of the pump shaft α=15°, the impeller diameter D=3.65m, and the rated speed n d =101r / min.

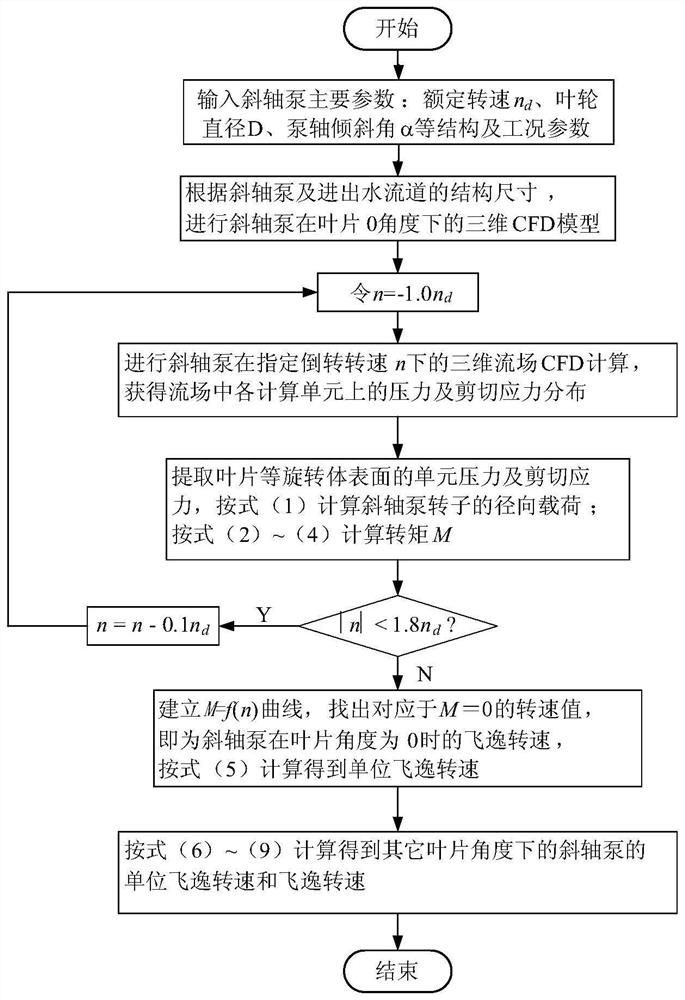

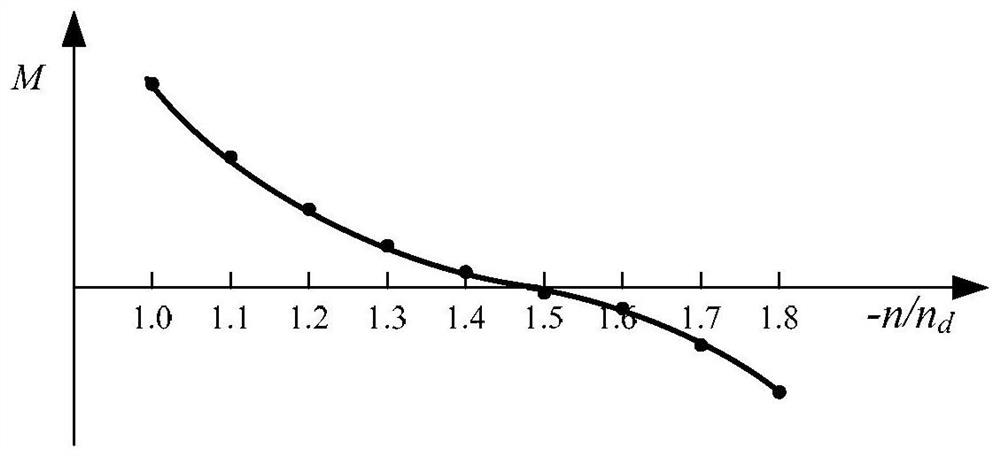

[0035] like figure 2 As shown, a method for determining the runaway speed of an inclined-axis pump at different blade angles provided according to this embodiment inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com