Box-type transformer base with drainage structure

A technology of box-type transformer and drainage structure, which is applied in transformer/inductance parts, transformer/reactor installation/support/suspension, electrical component structure association, etc., which can solve the problems of high cost, heavy weight, and inconvenient handling and transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

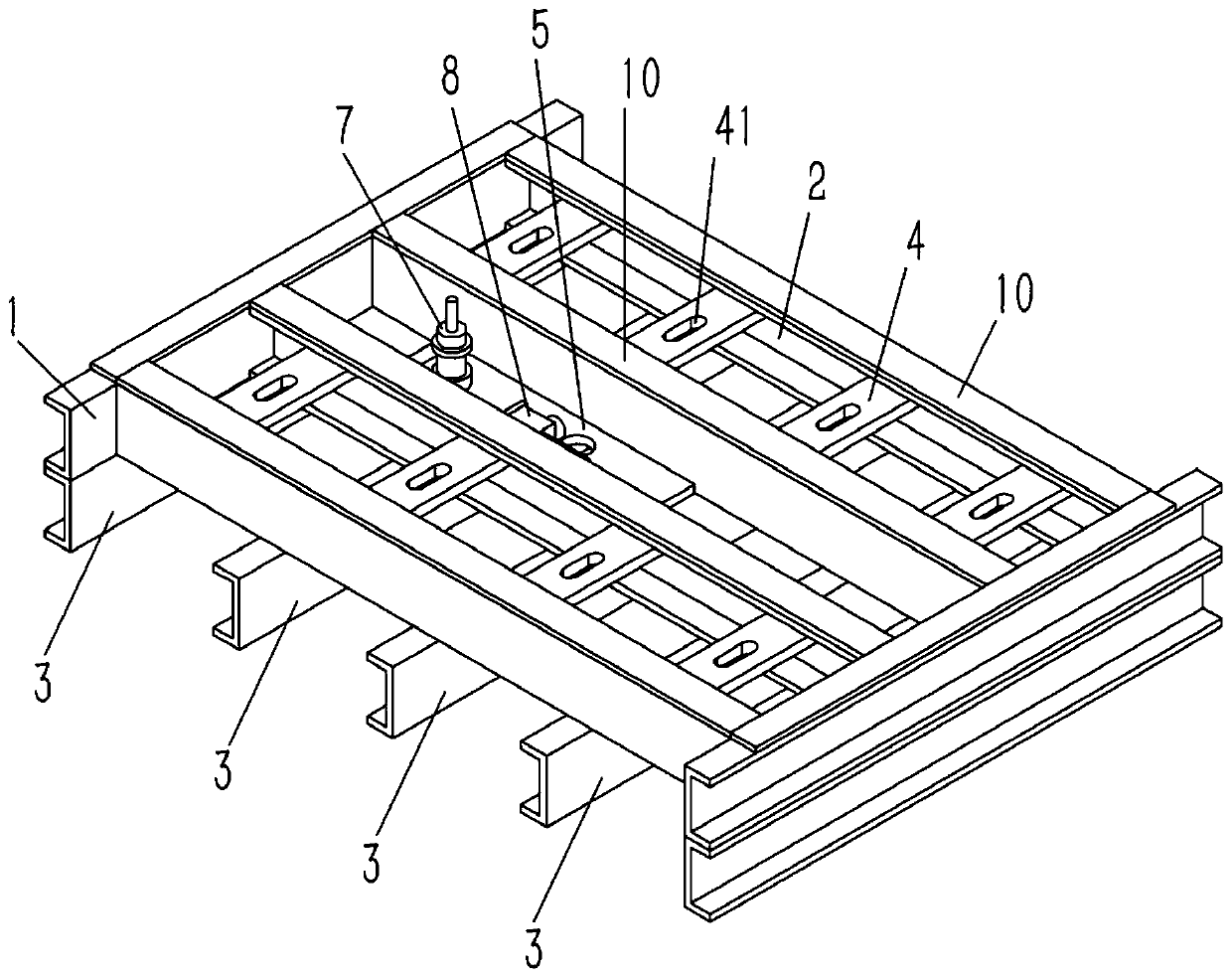

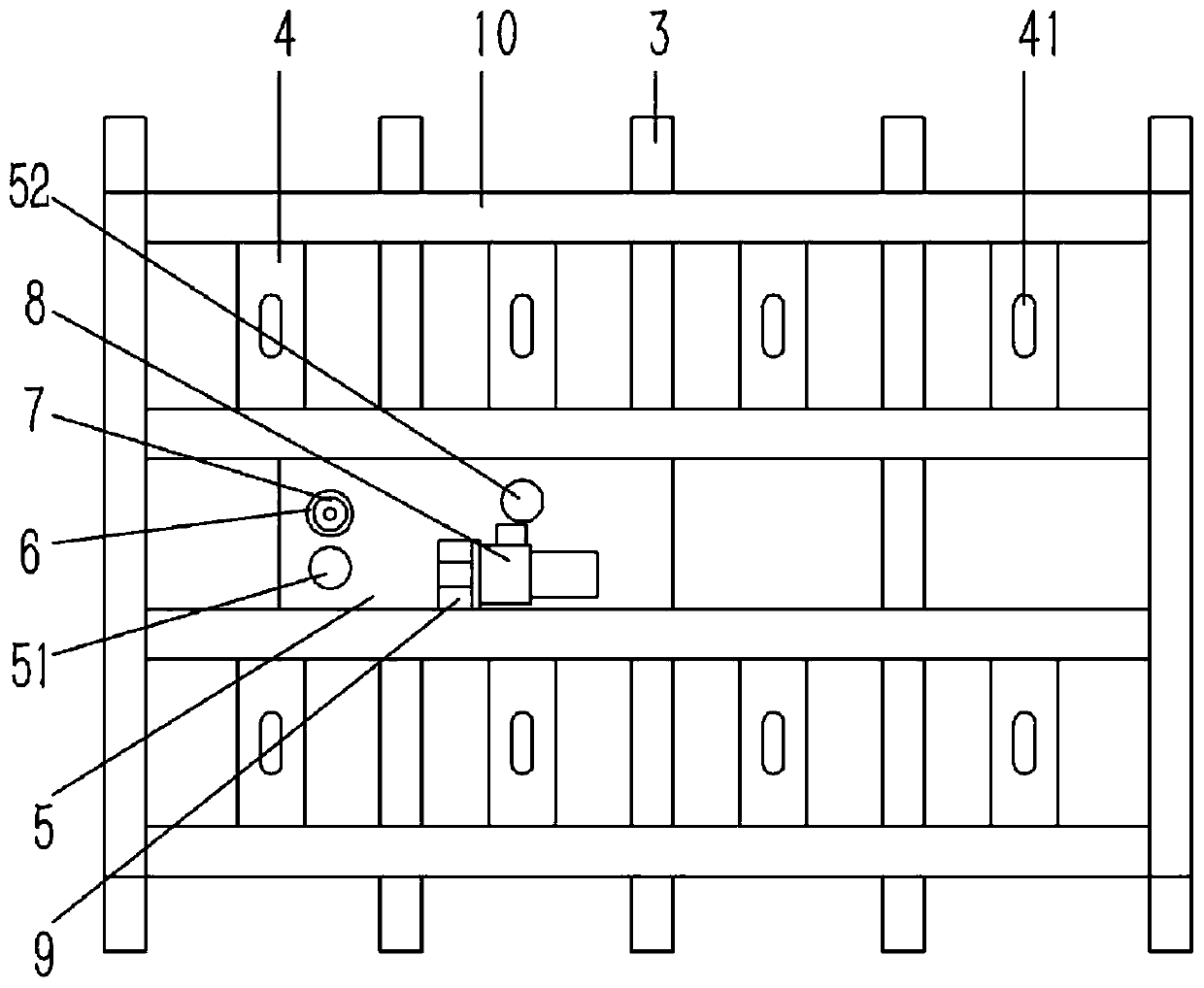

[0024] Example: see figure 1 , 2 As shown, a box-type transformer base with drainage structure includes an upper frame body, and the upper frame body includes first channel steels 1 opposite to each other longitudinally on both sides, and four horizontal second grooves are arranged between the first channel steels 1 Steel 2, the two ends of the second channel steel 2 are welded and fixed on the first channel steel 1, and the lower end faces of the second channel steel 2 and the first channel steel 1 are welded and fixed with some longitudinal third channel steels 3; A horizontal support plate 5 is arranged between the two second channel steels 2 in the middle of the first channel steel 1, and the support plate 5 is welded and fixed on the third channel steel 3, and the upper end surface of the support plate 5 is fixed with an annular The positioning sleeve 6 and the water pump mounting bracket 9 are fixed with a water pump 8 on the water pump mounting bracket 9, and the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com