A kind of thickening method of pla

A technology of tackifying auxiliary agent and silane coupling agent, which is applied in the field of tackifying PLA, can solve problems such as the decrease of crystallization rate, and achieve the effects of low cost, improved crystallinity and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

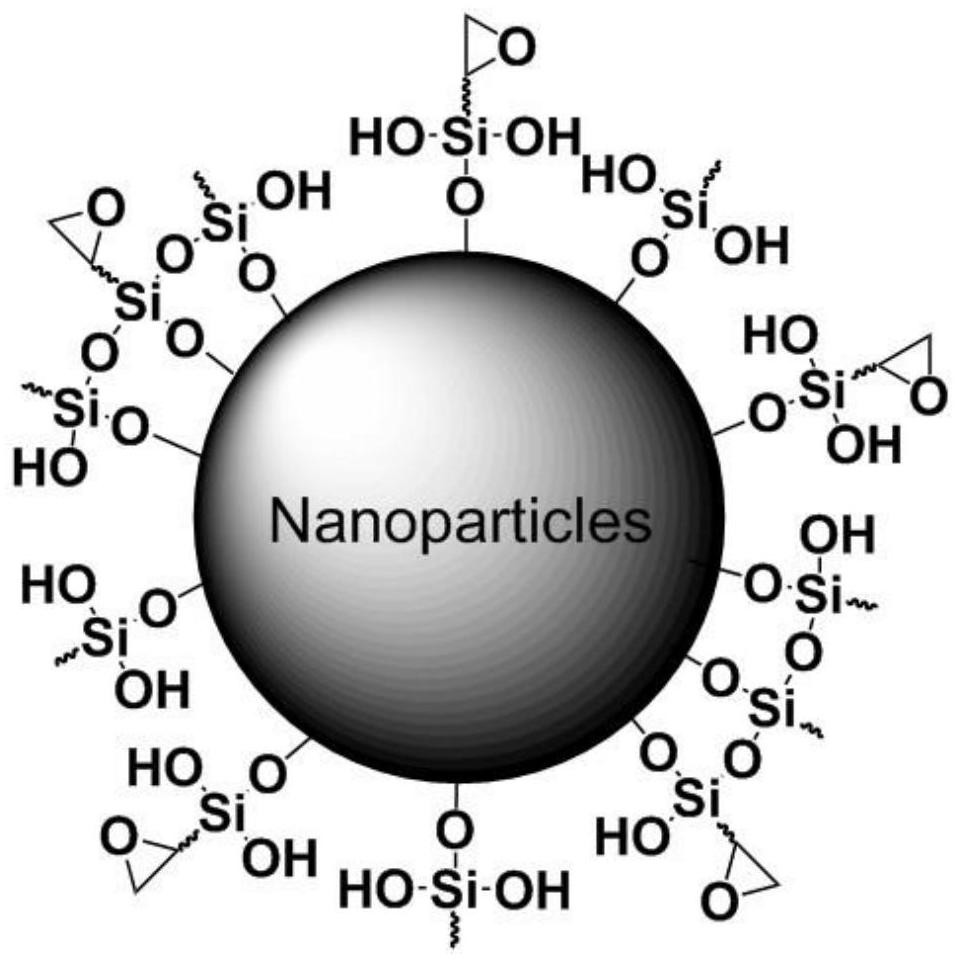

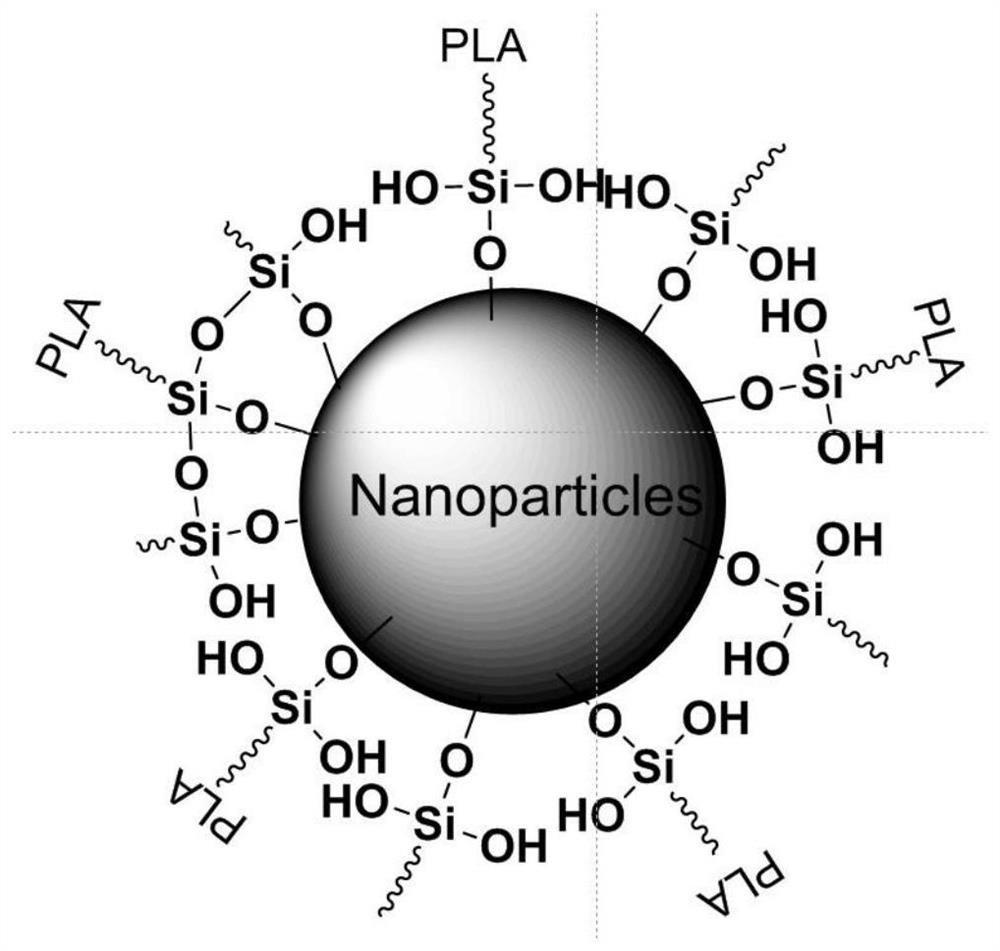

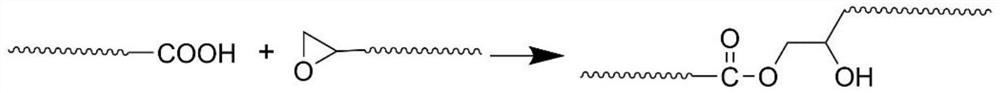

[0036] With 3L industrial alcohol (Anhui Ante Food Co., Ltd.), 300g SiO 2 (Wanjing New Materials Co., Ltd., VK-SP30), 2.84g γ-(2,3-epoxypropoxy)propyltrimethoxysilane (KH-560, 0.12mol) (Aladdin Shanghai Biochemical Co., Ltd.), 6.64 g of n-octyltriethoxysilane (KH-832, 0.24 mol) (Aladdin Shanghai Biochemical Co., Ltd.) (the molar ratio of the two siloxanes is 1:2), mixed evenly under mechanical stirring. Use 10wt% hydrochloric acid to adjust the pH to 4, fully stir the reaction (room temperature, pH ~ 4, 4h) and then centrifuge the resulting nano-slurry (10000rpm, desktop high-speed centrifuge, H / T16MM, Hunan Hexi Instrument Equipment Co., Ltd.) , the centrifuged solid nano-SiO 2 Dry in a blast oven for 12h (80°C) to obtain modified nano-SiO 2 particles.

[0037] The obtained modified nano-SiO 2 The particles were added with 1wt% in PLA (Natureworks, USA, type 4032d), and in a miniature conical twin-screw extruder (WLG10 / WZS10-D, Shanghai Xinshuo Precision Machinery Co., Lt...

Embodiment 2

[0041] Others are the same as in Example 1, but using 4.26g KH-560, 4.98g KH-832 (mol ratio is 1:1) to modify nano-SiO 2Particles were obtained to obtain modified PLA, and the effects of viscosity increasing and crystallization induction were measured. The results are shown in Table 2 below. It shows that the addition of chain extender does have a viscosity-increasing effect, and the crystallinity is slightly improved.

[0042] Table 2

[0043] Low frequency area (~1rad / s) High frequency area (~100rad / s) Crystallinity% Melt viscosity of unmodified PLA (Pa·s) ~180 ~100 13.2 Modified PLA melt viscosity (Pa·s) ~225 ~100 14.2

Embodiment 3

[0045] Others are the same as in Example 1, but adopt 5.68g KH-560, 3.32g KH-832 (mol ratio is 2:1) to modify nano-SiO 2 Particles were obtained to obtain modified PLA, and the effects of viscosity increasing and crystallization induction were measured. The results are shown in Table 3 below. It shows that the addition of chain extender does have a viscosity-increasing effect, and has little effect on crystallinity.

[0046] table 3

[0047] Low frequency area (~1rad / s) High frequency area (~100rad / s) Crystallinity% Melt viscosity of unmodified PLA (Pa·s) ~180 ~100 13.2 Modified PLA melt viscosity (Pa·s) ~230 ~105 13.9

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| stone rate | aaaaa | aaaaa |

| stone rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com