A PCT chain extension method

A chain-end, short-chain alkyl technology, applied in the field of chain extension of polyterephthalic acid/1,4-cyclohexanedimethanol ester, can solve the problems of expensive chain extenders and yellowing of color, and achieve The effect of low cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

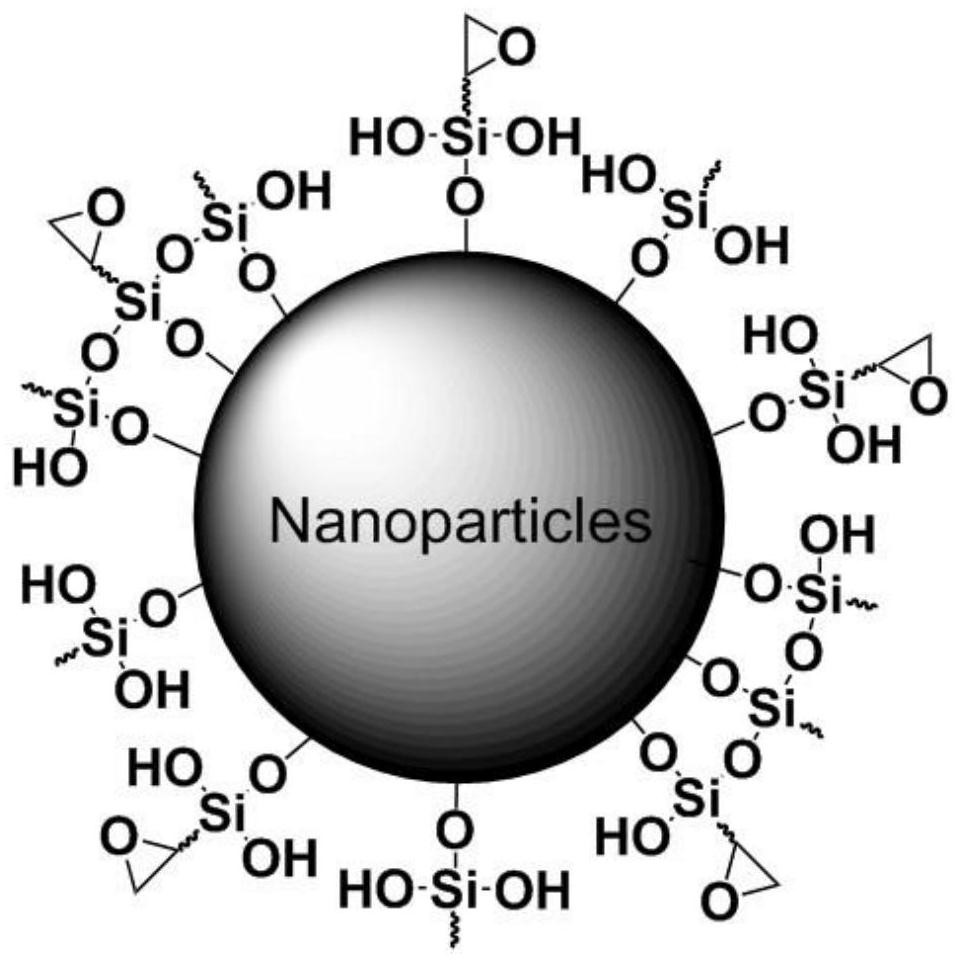

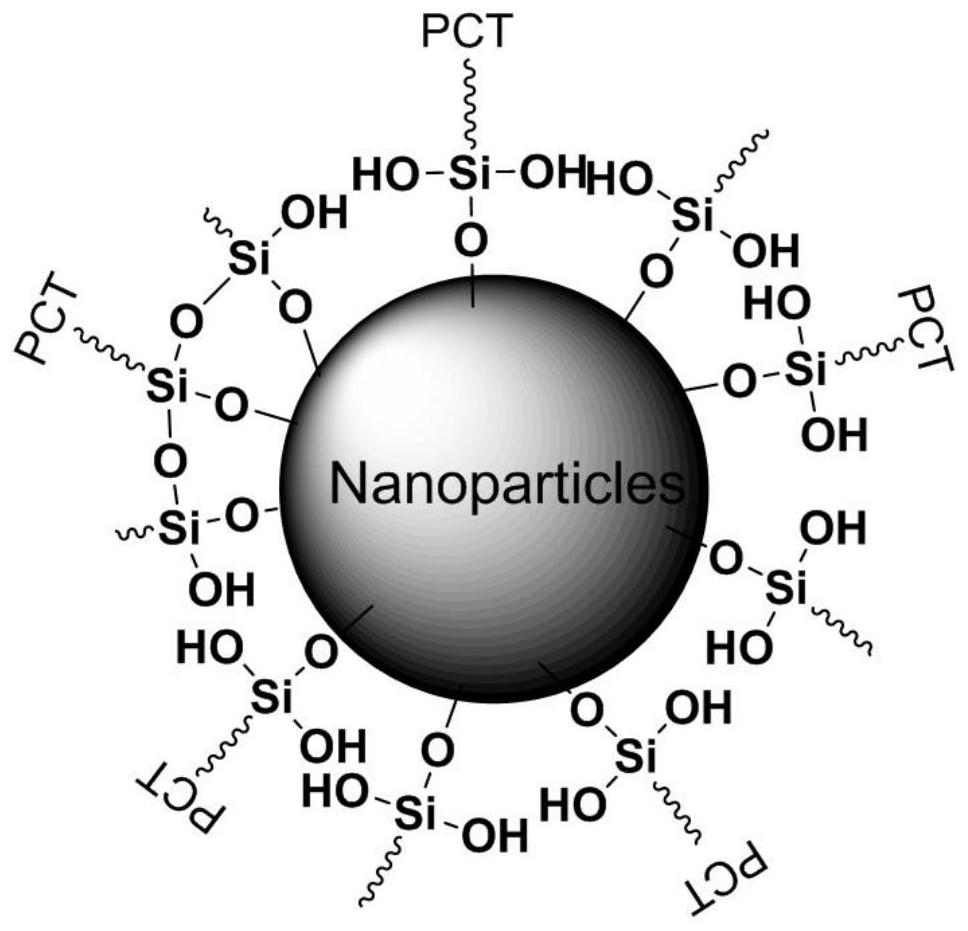

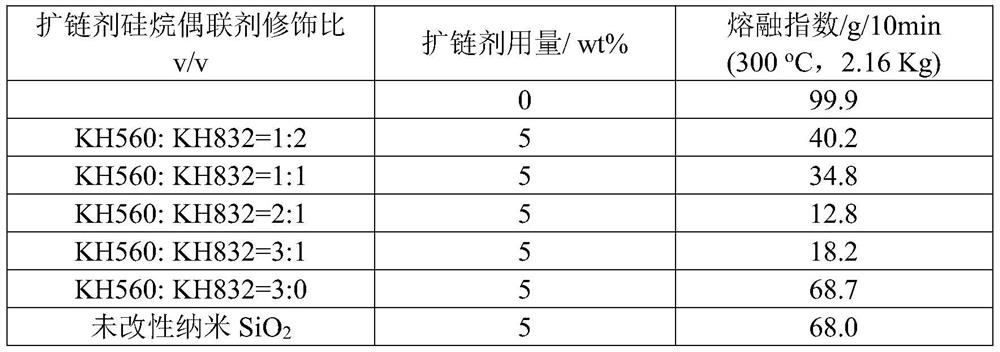

[0035] 480mL deionized water, 120mL industrial alcohol, 60g SiO 2 (Wanjing New Materials Co., Ltd., VK-SP30), 1.5mL γ-(2,3-epoxypropoxy)propyltrimethoxysilane (KH-560) (Aladdin Shanghai Biochemical Co., Ltd.), 3mL Triethoxysilane (KH-832) (Aladdin Shanghai Biochemical Co., Ltd.) (the volume ratio of the two siloxanes is 1:2), mix well under mechanical stirring, and then adjust the pH value with 10wt% dilute hydrochloric acid to 4, stirred at room temperature for 4 h to obtain a nanoslurry with a solid content of 10 wt%. After the resulting nano-slurry was spray-dried (190°C, the slurry inlet rate was 5mL / min), the modified nano-SiO 2 Particles are tackifiers.

[0036] The tackifier obtained above is added to PCT (Korean SK company, model 3402) (hand mixing gets final product), and the addition is 5wt% of PCT consumption, then in parallel twin-screw extruder (Labtech Engineering Company Ltd. ;Model: LTE20-40), at 280°C, 290°C, 285°C, 300°C (set sequentially from the feed to ...

Embodiment 2

[0038]Others are the same as in Example 1, but the volume ratio of KH560 / KH832 is changed to 1:1, that is, the volumes of KH560 and KH832 are both 2.25mL. It was found that the melting index dropped from 100g / 10min of pure PCT to 34.8g / 10min. It is proved that there is a chain extension effect.

Embodiment 3

[0040] Others are the same as in Example 1, but the volume ratio of KH560 / KH832 is changed to 2:1. That is, the volume of KH560 is 3mL, and the volume of KH832 is 1.5mL. It was found that the melting index dropped from 100g / 10min of pure PCT to 12.8g / 10min. It proves that the effect of chain extension is more obvious.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com