A kind of zinc oxide ink for printing electronics and its preparation method and use method

A technology of zinc oxide and electronics, applied in the direction of ink, application, household utensils, etc., to achieve the effect of strong stability, low curing temperature and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The composition of the zinc oxide ink for printed electronics in this embodiment is, by mass percentage, zinc acetate:ammonia water:ethanol=10%:25%:65%.

[0029] The preparation method of the printed electronic zinc oxide ink of the present embodiment comprises the following steps:

[0030] According to the formula of zinc oxide ink for printed electronics, first dissolve ammonia water in ethanol, mix for 10 minutes to achieve uniformity, then add zinc acetate to the mixture, stir for 3 hours at 25°C until dissolved, use 0.22μm micropores Zinc oxide ink for printed electronics is obtained after filtration by the filter membrane.

[0031] The usage method of the printed electronic zinc oxide ink of the present embodiment comprises the following steps:

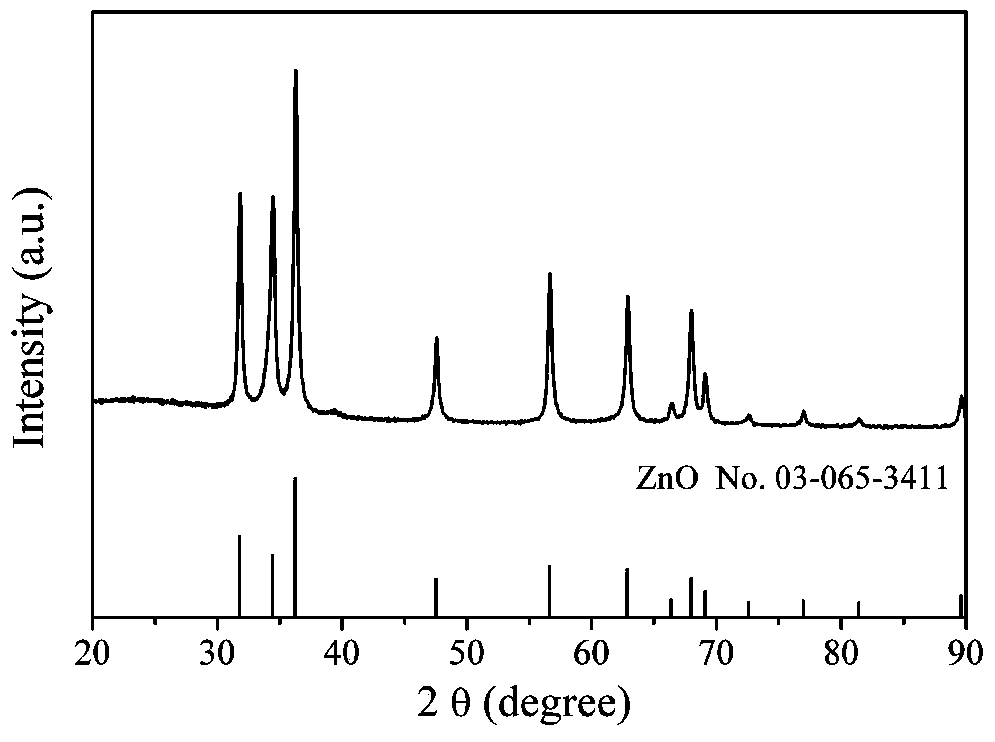

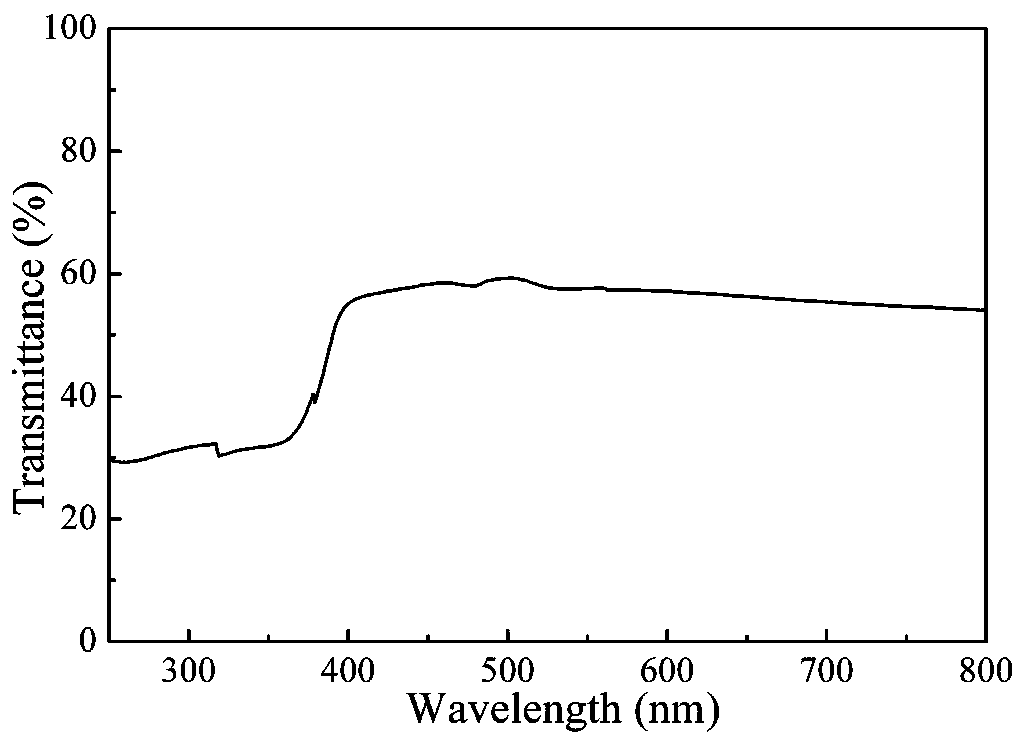

[0032] Zinc oxide ink for printed electronics was spin-coated on a glass substrate, heated with a heating plate in the air, and kept at 250°C for 10 minutes to obtain a zinc oxide film.

[0033] The viscosity of the zin...

Embodiment 2

[0035] The composition of the zinc oxide ink for printed electronics in this embodiment is, by mass percentage, zinc acetate: ethylenediamine: isopropanol = 45%: 30%: 25%.

[0036] The preparation method of the printed electronic zinc oxide ink of the present embodiment comprises the following steps:

[0037] According to the formula of zinc oxide ink for printed electronics, first dissolve ethylenediamine in isopropanol, mix for 8 minutes to achieve uniformity, then add zinc acetate to the mixture, stir at 25°C for 0.5h until dissolved, use Zinc oxide ink for printed electronics is obtained after filtration through a 0.22 μm microporous membrane.

[0038] The usage method of the printed electronic zinc oxide ink of the present embodiment comprises the following steps:

[0039] Coat the zinc oxide ink for printed electronics on the quartz substrate with a doctor blade, heat it in the air with a muffle furnace, and keep it at 330°C for 30 minutes to obtain a zinc oxide film. ...

Embodiment 3

[0042] The composition of the zinc oxide ink for printed electronics in this embodiment is, by mass percentage, zinc butyrate: isopropylamine: methanol: ethylene glycol = 40%: 37%: 15%: 7%.

[0043]The preparation method of the printed electronic zinc oxide ink of the present embodiment comprises the following steps:

[0044] According to the formula of zinc oxide ink for printed electronics, first dissolve isopropylamine in the mixed solution of methanol and ethylene glycol, mix for 10 minutes to achieve uniformity, then add zinc butyrate to the mixed solution, and stir at 25°C for 8 hours to Dissolve and filter through a 0.22 μm microporous membrane to obtain zinc oxide ink for printed electronics.

[0045] The usage method of the printed electronic zinc oxide ink of the present embodiment comprises the following steps:

[0046] Coating the zinc oxide ink wire bar for printed electronics on the glass substrate, heating in the air with a muffle furnace, and keeping the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com