Auxiliary moving structure

A technology of rotating parts and moving parts, applied in mechanical equipment, fixing devices, etc., can solve the problems of difficult assembly and disassembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

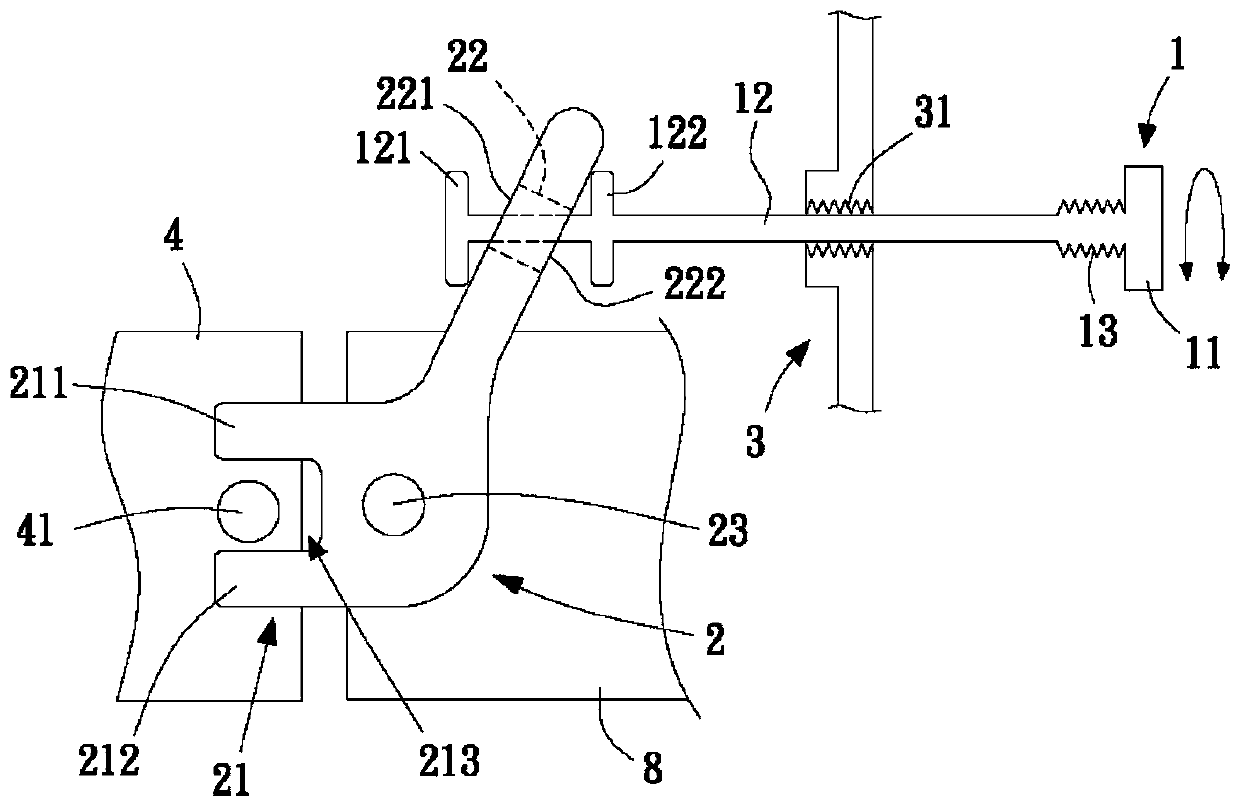

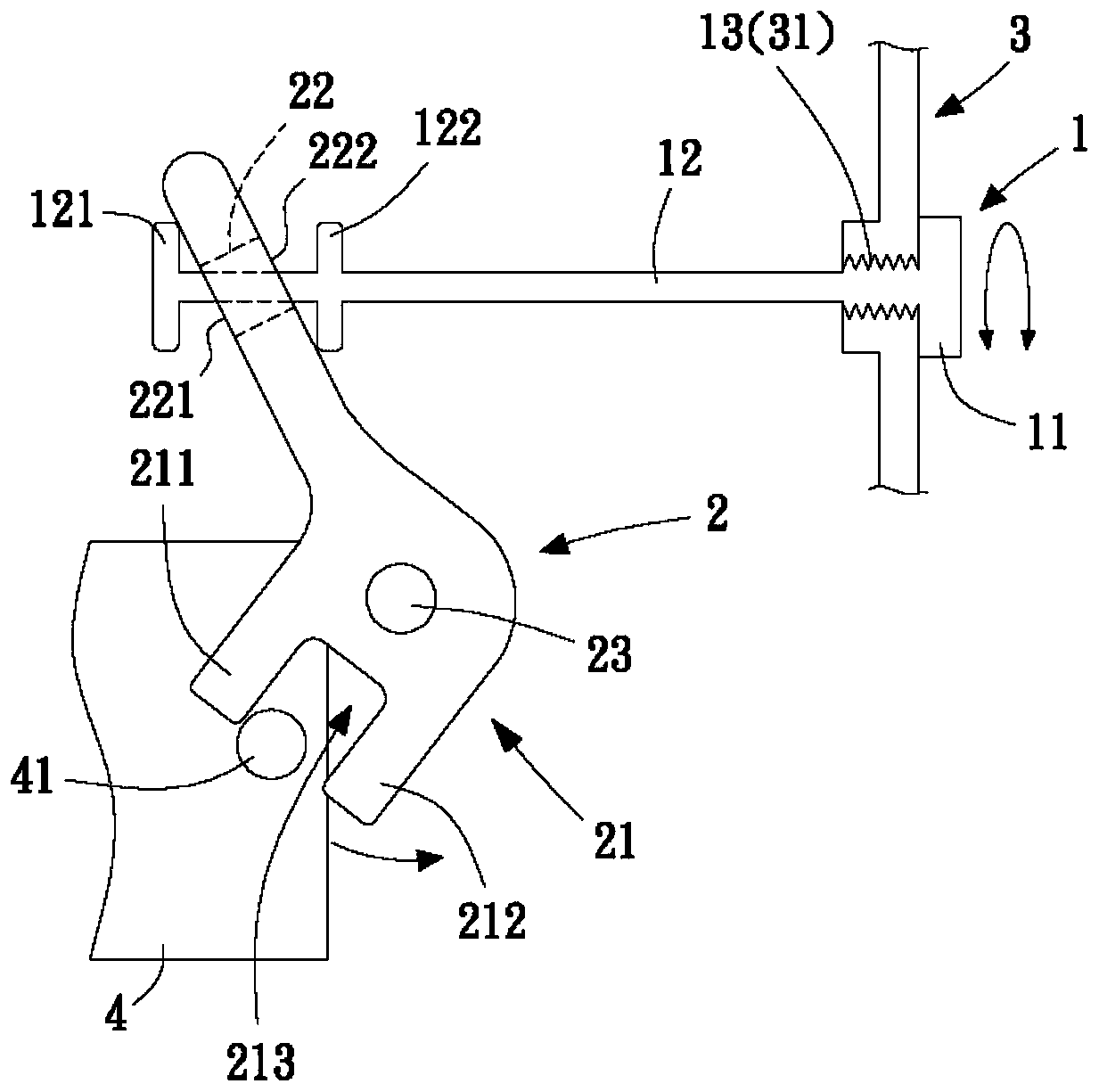

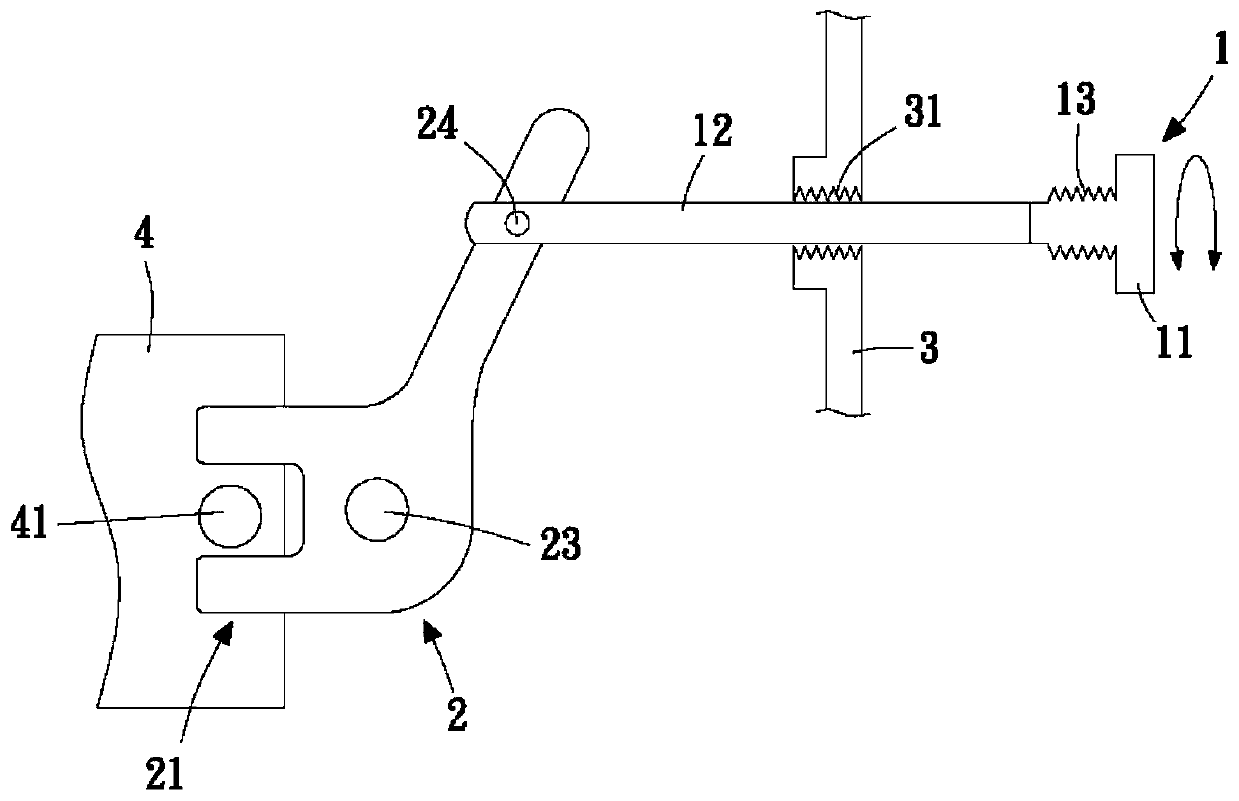

[0104] The following will further illustrate the driving-assisting structure of the embodiment of the present invention with reference to the accompanying drawings.

[0105] Please refer to figure 1 and figure 2 , as shown in the figure, the present invention provides a driving-assist structure, which includes a rotating member 1 and a blocking member 2 .

[0106] The rotating member 1 has an operating portion 11 and an actuating body portion 12 , and the actuating body portion 12 has a rotating portion 13 .

[0107] The abutting member 2 is movably assembled with the actuating body part 12, the abutting member 2 has an abutting part 21, and the rotating part 13 is used to cooperate with the corresponding rotating part 31 of the first object 3 to rotate. move, and then drive the blocking part 21 of the blocking member 2 to carry out blocking, position limiting, relative movement, driving, lever movement, Assembling, torque movement, helical force pushing, helical force pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com