Anti-shearing protective sleeve for connecting part of steel-plastic conversion pipe fitting

A technology for steel-plastic conversion and connection parts, which is applied in pipeline protection, pipeline anticorrosion/rust protection, pipes/pipe joints/pipe fittings, etc. It can solve problems such as weak resistance to ground subsidence, and achieve guaranteed strength and normal operation , to reduce the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

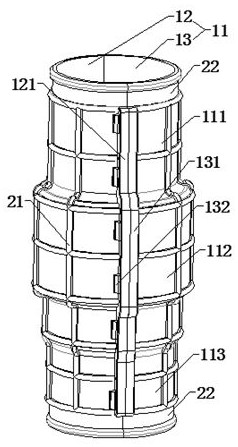

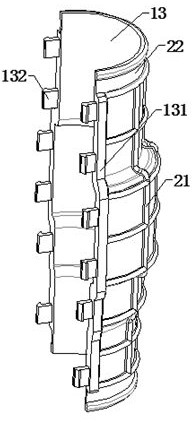

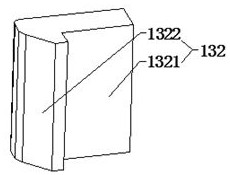

[0037] A kind of anti-shear protective sleeve of the connecting part of steel-plastic conversion pipe fitting in the preferred embodiment of the present invention, such as Figure 1-4 As shown, the protective cover main body 11 is axially divided into a first protective cover 12 and a second protective cover 13, so that the first protective cover 12 and the second protective cover 13 are hollowed out semi-cylindrical, so The section of the first protective cover 12 is provided with a first installation part 121, and the first installation part 121 is provided with a plurality of first through holes 122; the section of the second protective cover 13 is provided with the same A second installation part 131 corresponding to the first installation part 121, the second installation part 131 is provided with a lock 132 corresponding to the first through hole 122, the first protective cover 12 and the second protective cover 13 buckle synthetic protective cover main body 11; the side...

Embodiment 2

[0046] Such as Figure 5-7 As shown, the difference from Embodiment 1 is that in this embodiment, a lock cylinder 123 and a lock sleeve 124 corresponding to the lock cylinder 123 are also included, and the first mounting part 121 is provided with a The second through hole corresponding to the lock post 123, the first connecting portion 1321 is provided with a third through hole corresponding to the second through hole; the lock post 123 passes through the second through hole and the second through hole. The third through hole is described; the lower end of the lock cylinder 123 is provided with a thread corresponding to the lock sleeve 124; the upper end of the lock cylinder 123 is provided with a limit block, and the lower end is provided with a thread corresponding to the lock sleeve 124, so that the lock cylinder 123 runs through the second The second through hole and the third through hole are tightened through the locking sleeve 124 , and the stability of the installation...

Embodiment 3

[0048] Such as Figure 8-9 As shown, the difference from Embodiment 1 is that in this embodiment, the two ends of the protective cover body 11 are also provided with locking strips 23 extending toward the axis, and the outer wall of the steel-plastic conversion pipe is provided with a The groove corresponding to the locking strip 23; after the groove is provided on the outer wall of the steel-plastic conversion pipe fitting, when the protective cover is installed, the alignment can be quickly performed, and after the main body of the protective cover 11 is installed, the protective cover slips Condition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com