Magnetostrictive ultrasonic fluid valve

A technology of magnetostrictive and magnetostrictive materials, which is used in lift valves, valve details, diaphragm valves, etc., can solve the problems of difficult miniaturization and small deformation of piezoelectric materials, and achieves simple processing, compact structure, and easy engineering. effect of the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following descriptions are only preferred implementations of the present invention, and the scope of protection is not limited to this embodiment. All technical solutions under the idea of the present invention shall belong to the scope of protection of the present invention. At the same time, it should be pointed out that for those skilled in the art, some improvements and modifications without departing from the principle of the present invention should also be regarded as the protection scope of the present invention.

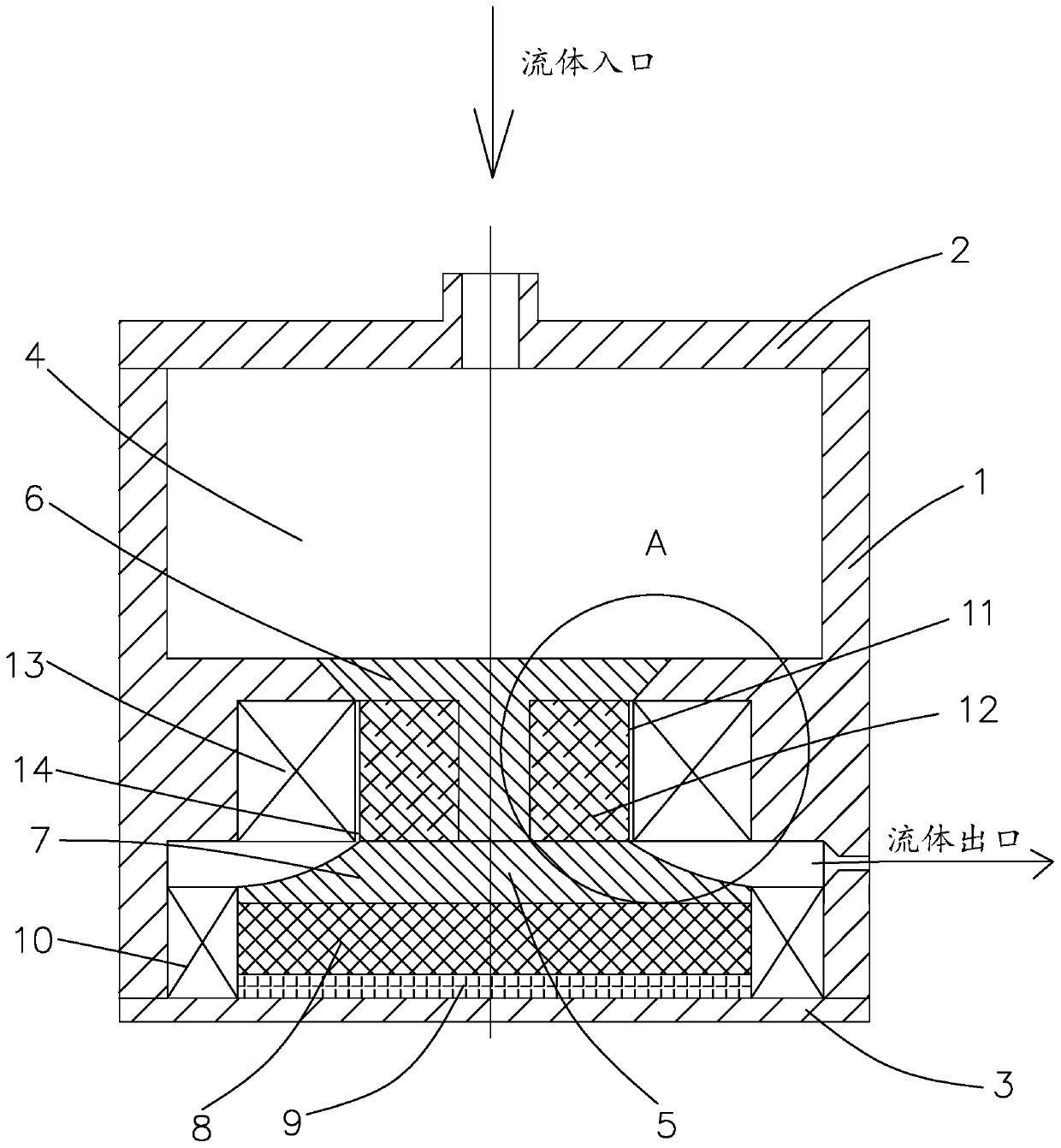

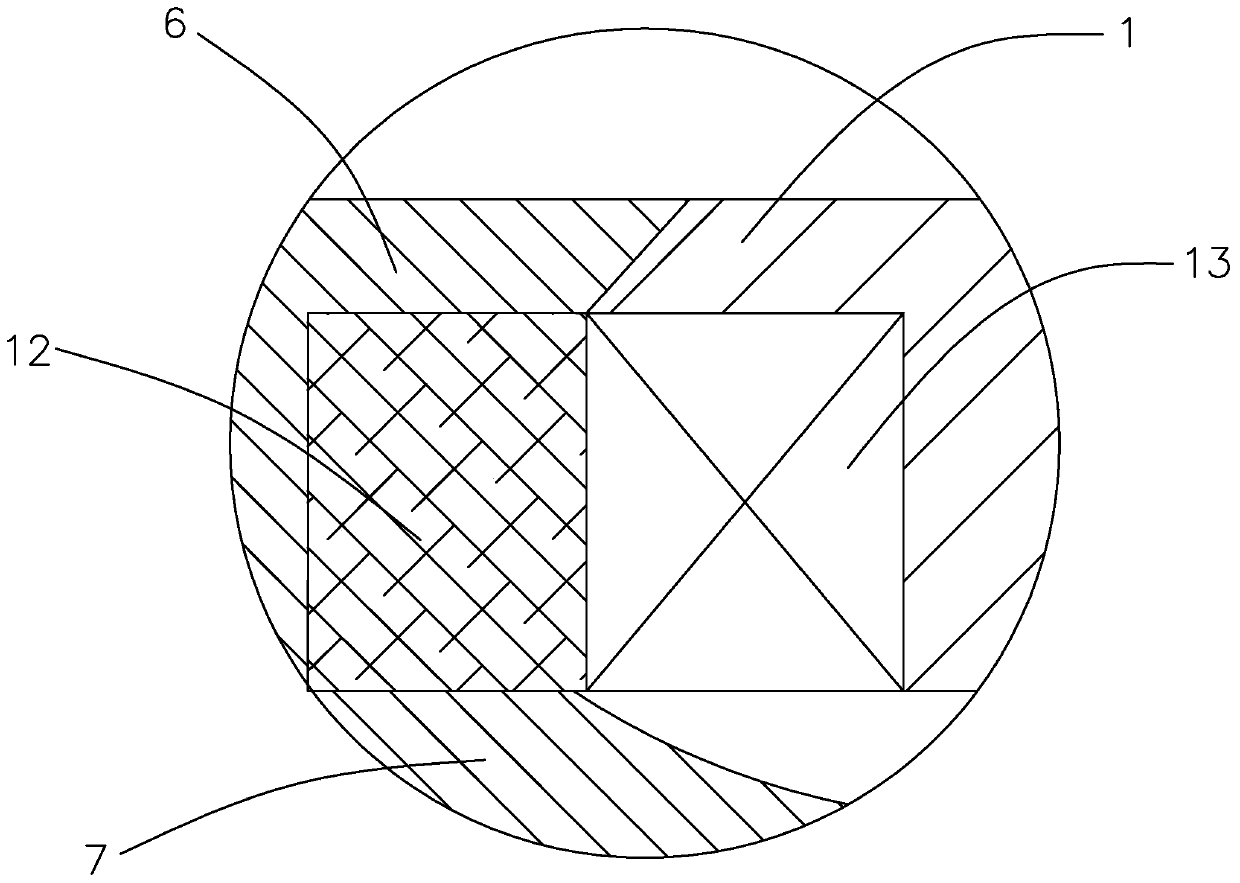

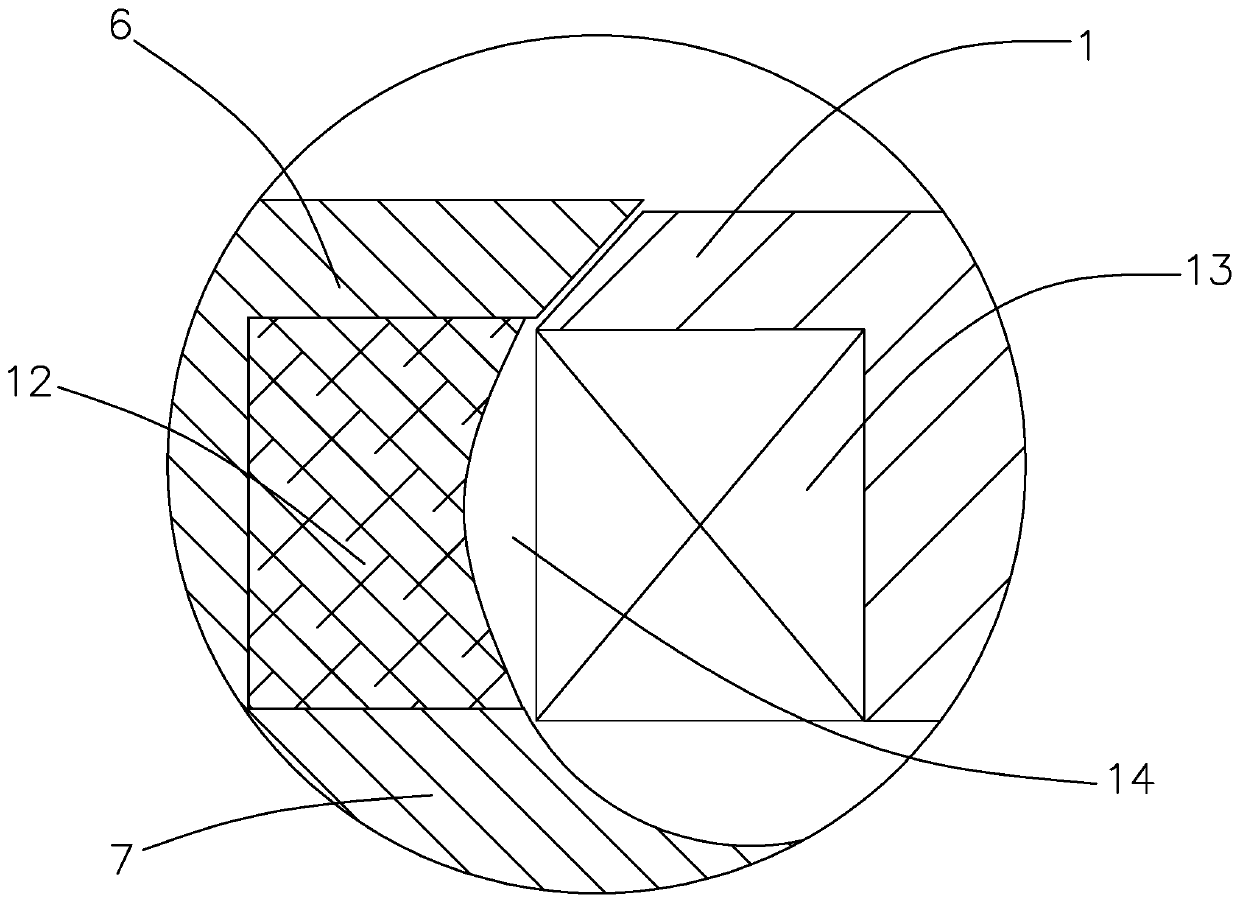

[0021] Such as Figure 1 to Figure 3 As shown, a magnetostrictive ultrasonic fluid valve includes a valve body 1, an upper end cover 2 and a lower end cover 3, the right side of the valve body 1 is provided with a fluid outlet, and the center of the upper end cover 2 has a fluid inlet, the valve body 1 and the upper end cover There is a fluid chamber 4 between the two, and an ultrasonic chamber 5 is provided between the valve body 1 and the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com