A liquid nitrogen refrigeration device composite variable temperature refrigeration temperature coupling mechanism

A technology of liquid nitrogen refrigeration and coupling mechanism, which is applied in the field of low temperature in space, can solve the problems of increased liquid nitrogen loss, difficulty in achieving the purpose of refrigeration, and reduction of effective working time, and achieves shortened cooling time, good consistency, and avoidance of temperature loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

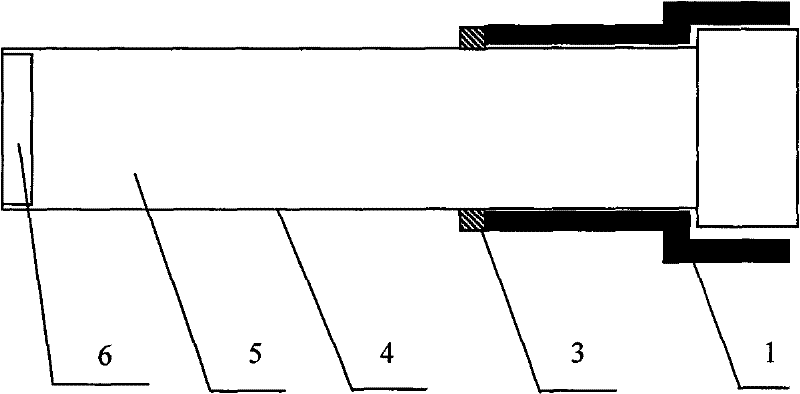

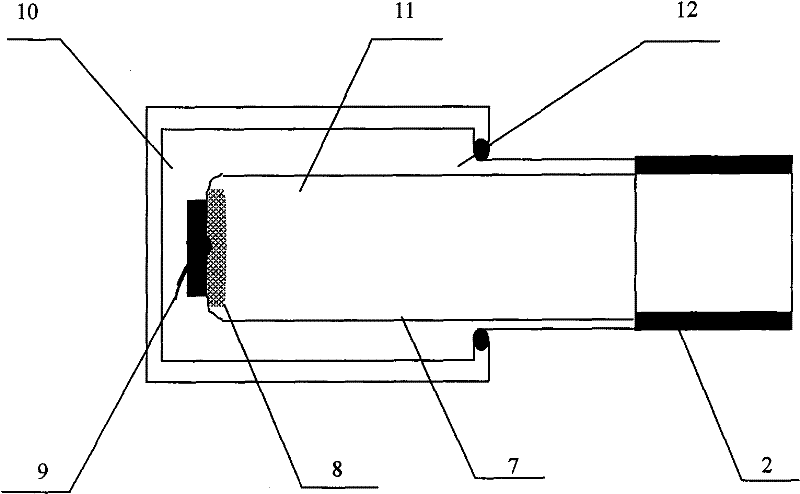

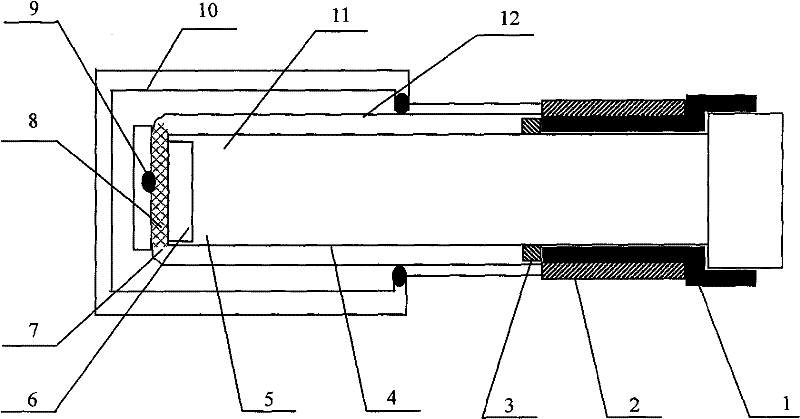

[0019] Using the dynamic compression screw sleeve 1, the fixed screw compression nut 2 and the positioning composite structure, the cold storage tube 3 and the cold head 4 are squeezed to the hot end through the temperature adjustment gap 7 in the axial direction, and the heat exchange is completed through the solid heat conduction of the heat conduction material . Since the fixed screw compression nut 2 is integrated with the cooled detector 9 and the detector Dewar 10, the fixed screw compression nut 2 is made of a section of M12 internal thread with a length of 6 mm, such as figure 2 As shown, the relative positions of the three are unchanged after the assembly is completed. The dynamic compression screw sleeve 1, the guide positioning ring 2, the cold storage tube 4, and the cold head 6 constitute axial moving parts, wherein the dynamic compression screw sleeve 1 is composed of a M12×0.75mm long 10mm external thread section and a manual rotation operation section A stepp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com