Wind turbine blades for broadband active control

A technology of wind power generator and active control, which is applied in the direction of wind power generator, control of wind power generator, wind power generation, etc. It can solve problems such as increased surface resistance of wind power blades, decreased system reliability, weak momentum output capability, etc., and achieves local control The effect of strong ability, small additional weight and wide response frequency range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0030] The present invention will be described in detail below with reference to the accompanying drawings and examples.

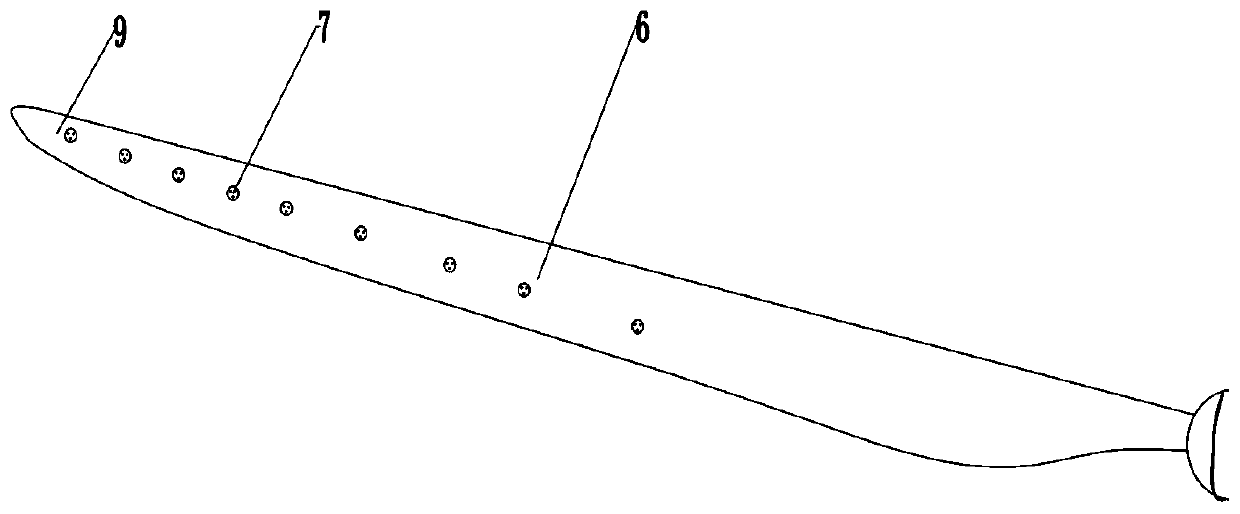

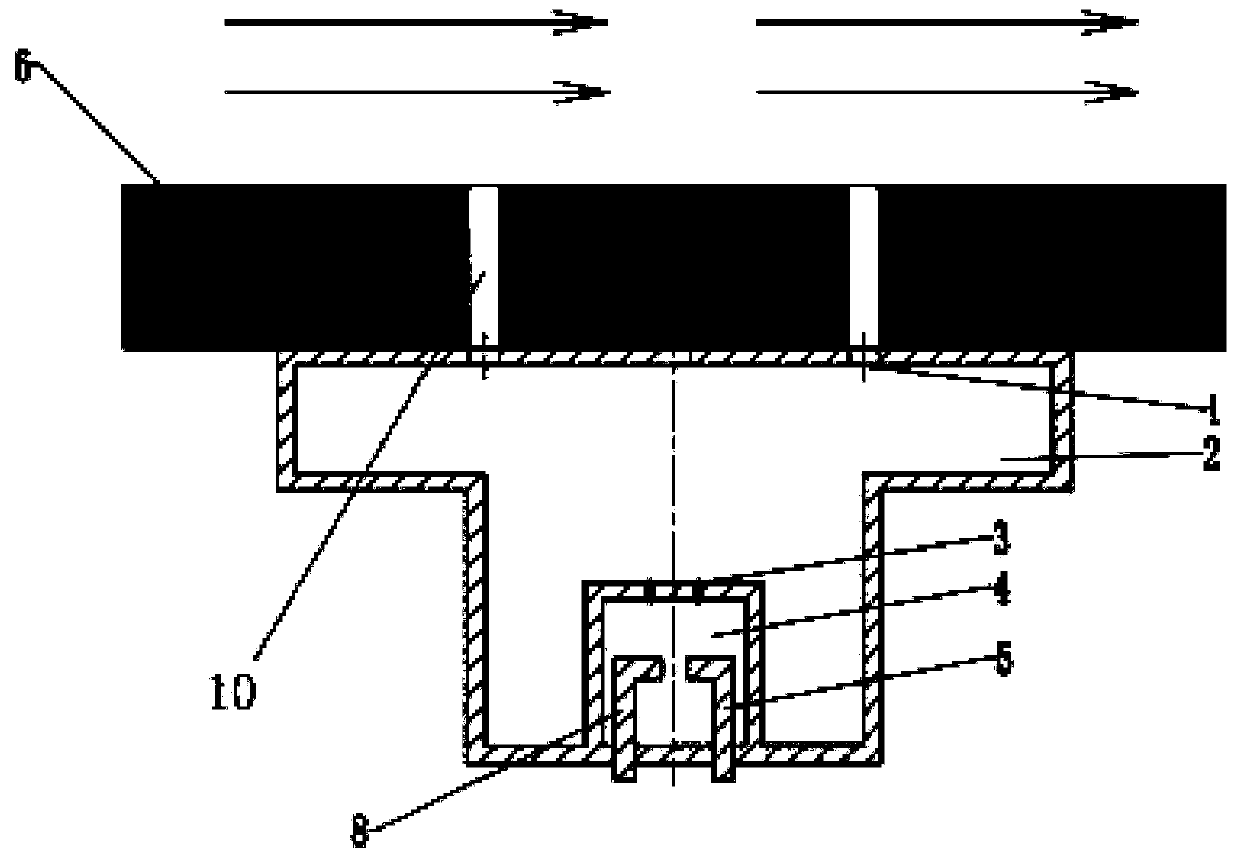

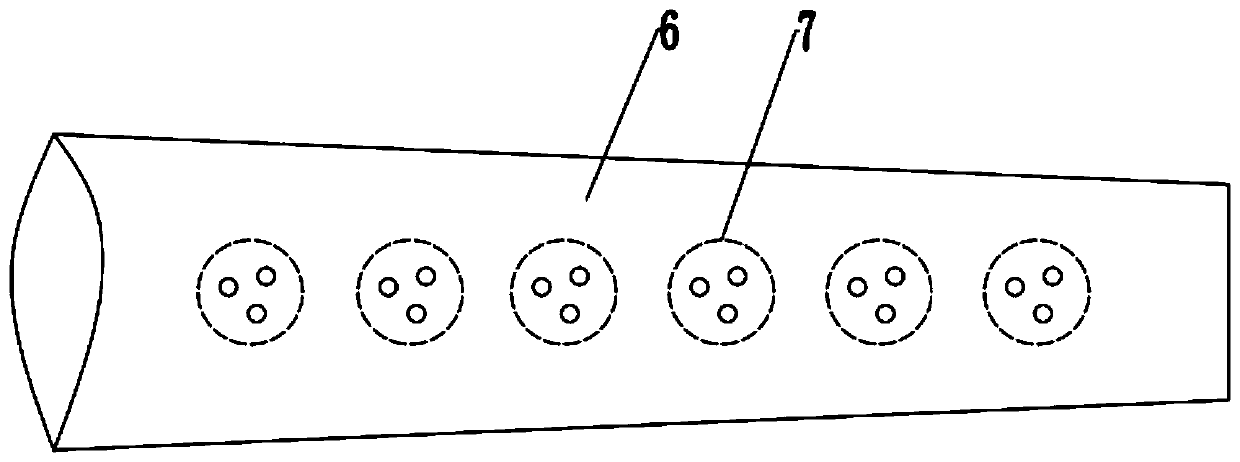

[0031] Such as Figure 1-Figure 2 As shown, a wind power generator blade for broadband active control, which includes a blade body 6 and several low Reynolds number plasma synthetic jet actuators 7, and several low Reynolds number plasma synthetic jet actuators 7 are arranged on the blade Under the surface of the body 6, several low Reynolds number plasma synthetic jet actuators 7 are arranged along the upstream side of the airflow separation line on the surface of the blade body 6, and are mainly arranged at the high-lift section 9 near the blade tip, on the surface of the blade body A plurality of jet outlets 10 communicating with the jet outlets of the low Reynolds number plasma synt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com