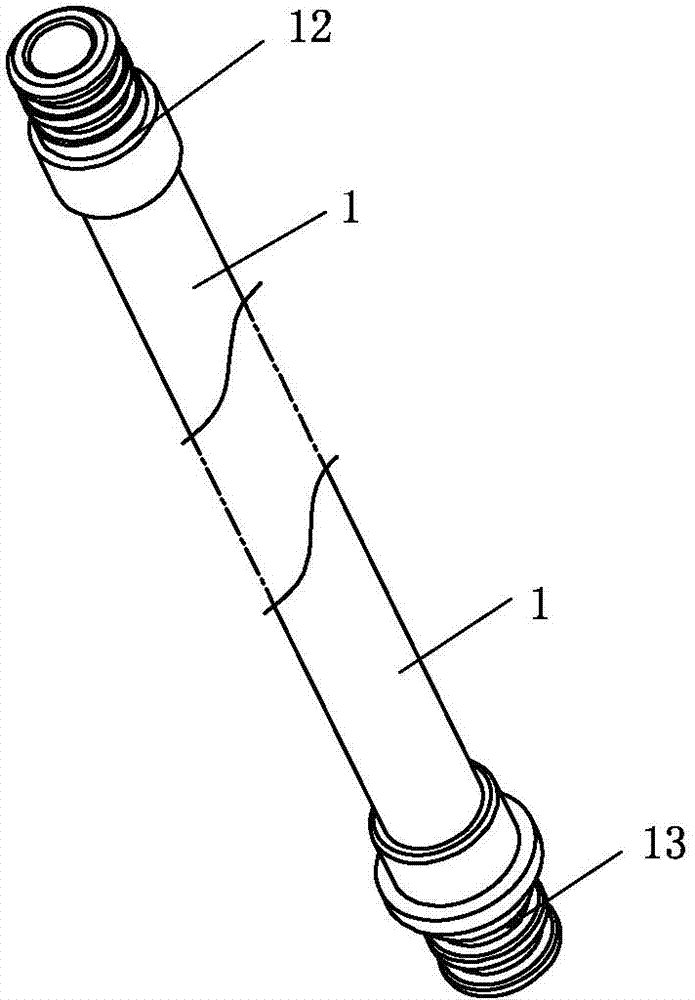

Mold for manufacturing plastic hose with joints and method for manufacturing plastic hose with joints at both ends

A technology for plastic hoses and joints, applied in the direction of coating, etc., can solve the problems of products not suitable for use in occasions with strict leakage requirements, leakage, etc., and achieve high product quality stability, simple additional structure, and easy promotion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

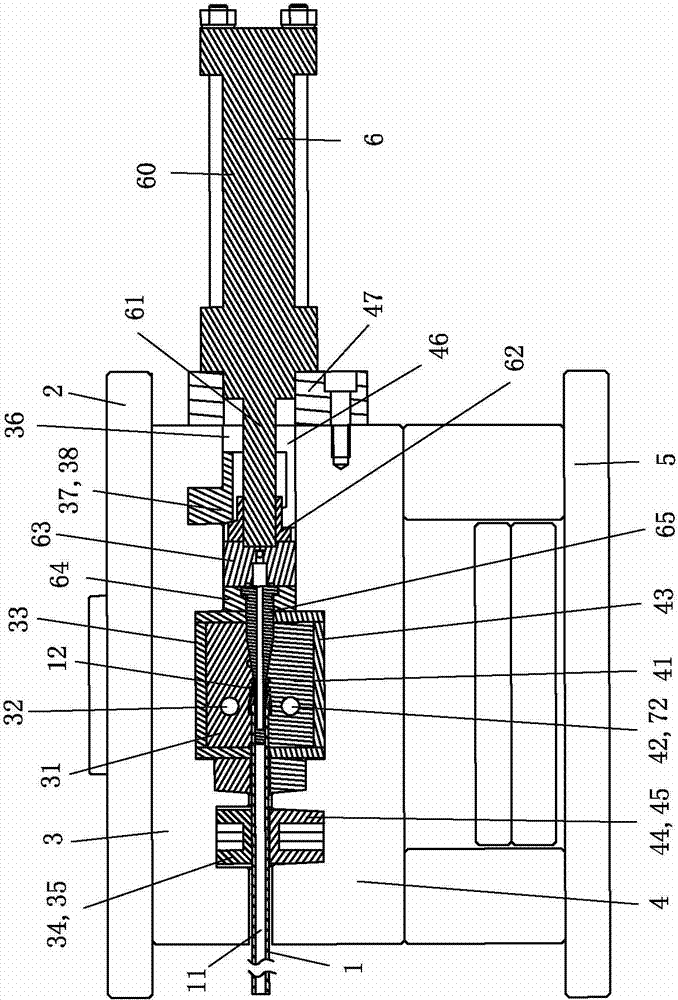

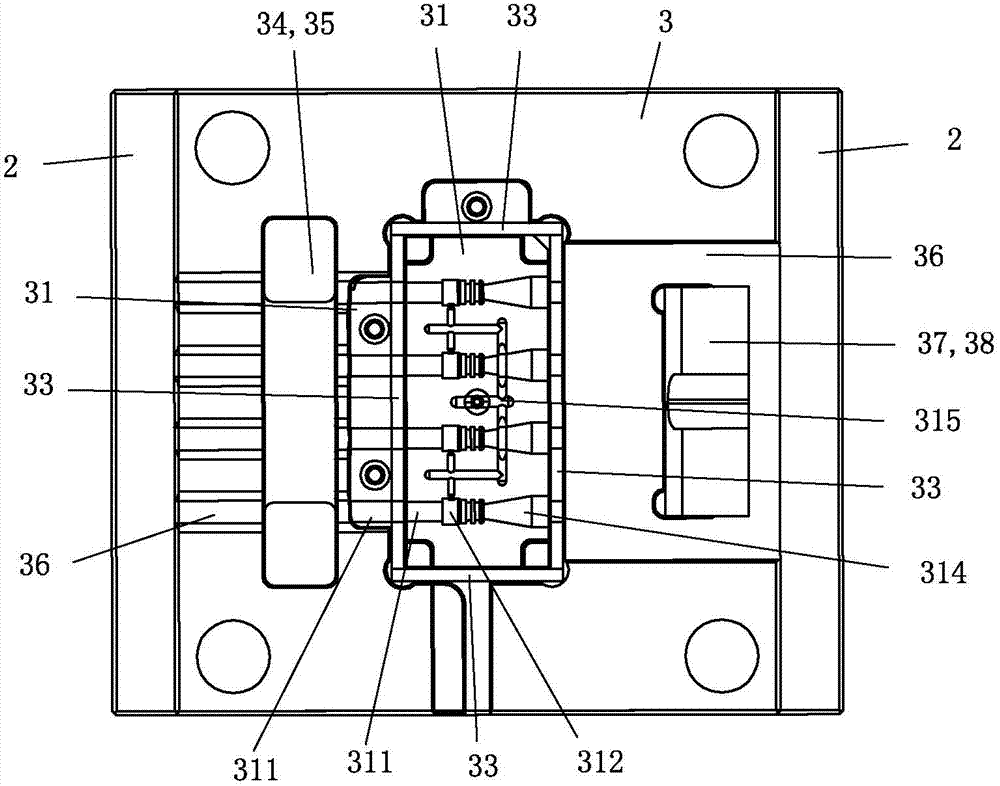

[0022] The present invention manufactures an embodiment of the mold of the plastic hose that has joint portion, as figure 2 As shown, the mold has a top plate 2, a fixed template 3, a fixed mold core 31, a movable template 4, a movable mold core 41, a bottom plate 5, a core pulling mechanism 6 and a heating mechanism.

[0023] The fixed template 3 is fixed on the top plate 2, and the fixed mold core 31 is fixed on the center of the fixed template 3 mold opening surface. The first heating element 71 in the heating mechanism is arranged in the mounting hole 32 inside the fixed mold core 31, and the fixed template 3 is provided with a box-shaped heat insulating material 33 to isolate the fixed mold core 31. The box-shaped heat insulating material 33 The open end of is consistent with the working surface of fixed die core 31. On the right side of the fixed formwork 3, there is a semi-cylindrical relief groove 36 extending uniformly from the right end surface of the fixed formwor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com