Electricity-leakage-preventive piezoelectric ceramic igniter body plastic shell

A technology of piezoelectric ceramics and igniters, which is applied in the field of leakage-proof voltage electric ceramic igniter body plastic shells, can solve problems such as failure to achieve results, leakage, and complicated procedures, and achieve the effect of simplifying the assembly process and eliminating hidden dangers of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

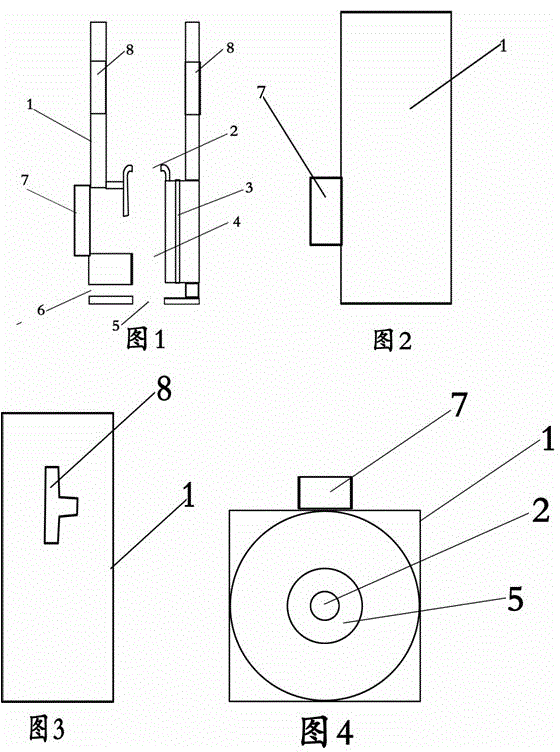

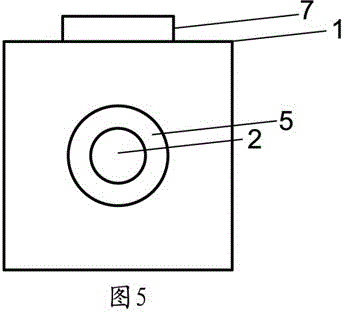

[0013] exist figure 1 , 2 , 3, 4, and 5, when the present invention is matched and assembled, in the plastic shell 1 of the body, a small cap nail is pressed into the small cap nail hole 2, and a conductive nail is pressed into the piezoelectric ceramic from the bottom hole 5 at position 3. At position 4, put the copper sheet at position 4, and put piezoelectric ceramics at position 4 from the bottom hole 5. Press the metal plate into the electrode square hole 6, so that the plastic shell of the main body and the parts to be assembled are integrated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com