Accessible roof heat-insulation leveling layer with water and air discharging system

A technology of emission system and leveling layer, applied in the direction of roof covering layer, roof, ventilation system, etc., can solve the problems of easily disturbed leakage sealing, hindering people's activities, affecting the appearance of roof decoration, etc., to improve the overall aesthetic feeling , The effect of a spacious and comfortable activity space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] One, structure description of the present invention:

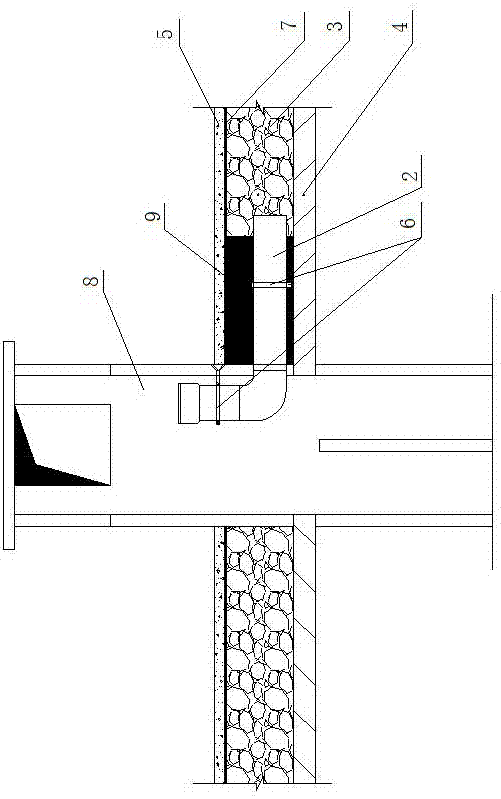

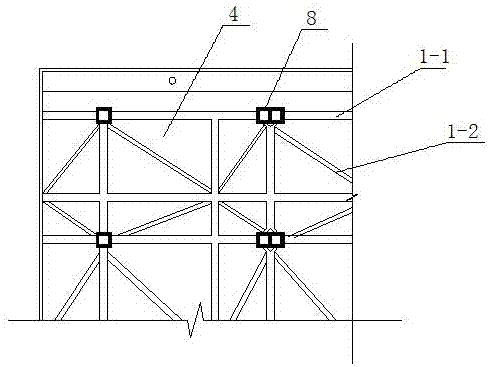

[0014] Such as figure 1 , 2 As shown, on the cast-in-place panel 4, the main pipeline 1-1 is arranged vertically and horizontally on the entire roof. A drainage air channel arranged horizontally in a grid pattern is formed.

[0015] When the intersection of each main pipe 1-1 just meets the toilet drainage channel (or oil fume discharge channel) 8 arranged on the cast-in-place roof panel 4, then this point is set as an exhaust elbow 2 Set up points.

[0016] Lay bean stones 3 in the drainage air duct (including all main pipes 1-1 and branch pipes 1-2), respectively cover linoleum 7 on top of all main pipes 1-1 and branch pipes 1-2, and then cover linoleum 7 Make cement mortar leveling layer 5 above.

[0017] At the establishment point of each set exhaust elbow 2, an L-shaped exhaust elbow 2 connected to the drain air passage is arranged on the side of the main pipe 1-1, and the exhaust elbow 2 can be separated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com