Heat insulating method with foamed plastics for building roof

A plastic foam and top plastic technology, applied in the direction of roof insulation materials, etc., can solve the problems of increasing the wind receiving area, high cost, roof overturning, etc., and achieve the effect of wide application prospect, simple operation and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The dense plastic foam board used in the present invention is generally a rectangular plate with a width of 1 meter, a length of 1.5 meters, and a thickness of 0.05 meters. Some of the plates will have a gap of 0.025 meters square on one corner of the plate for placing small bricks. and other supports.

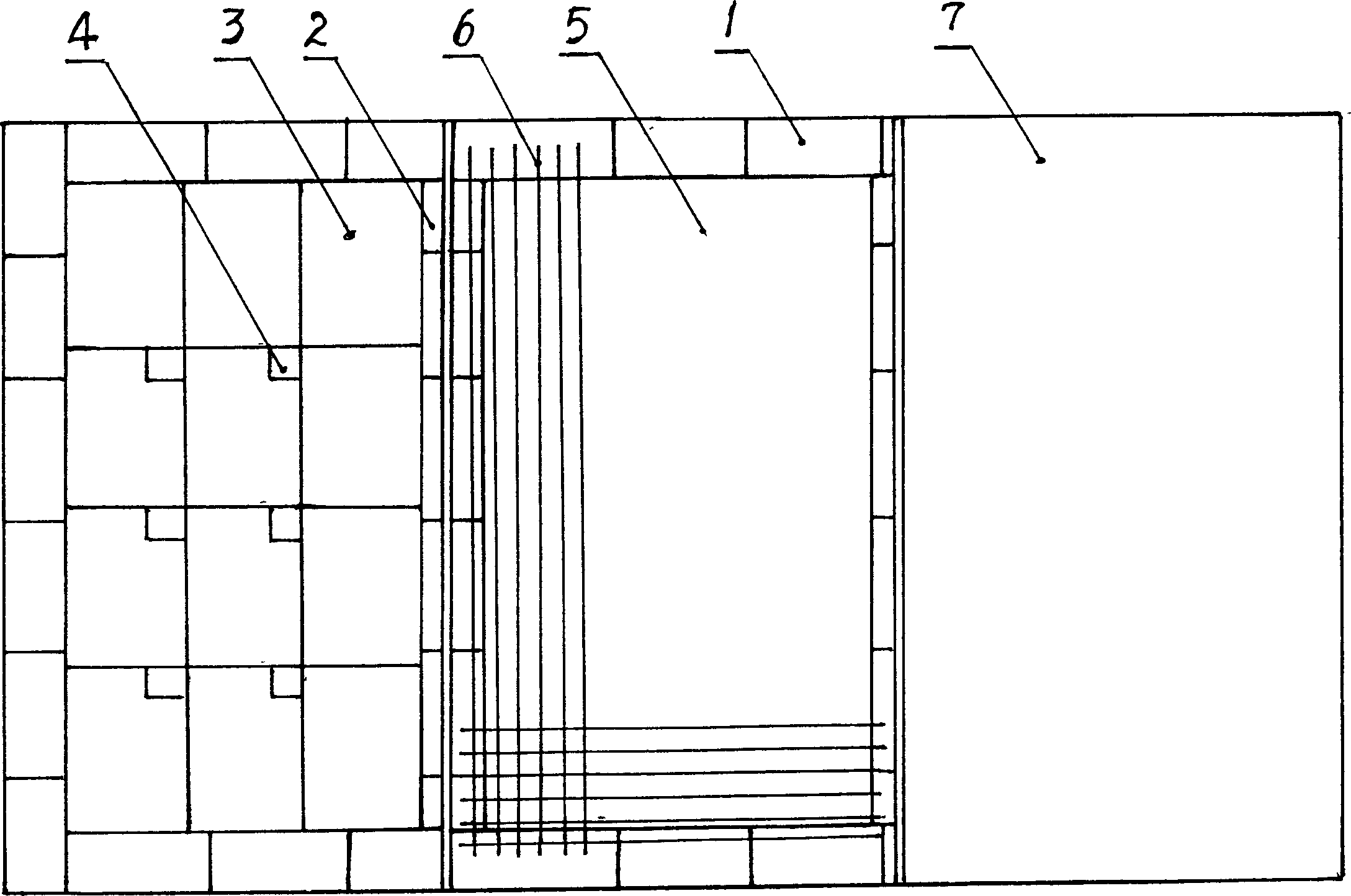

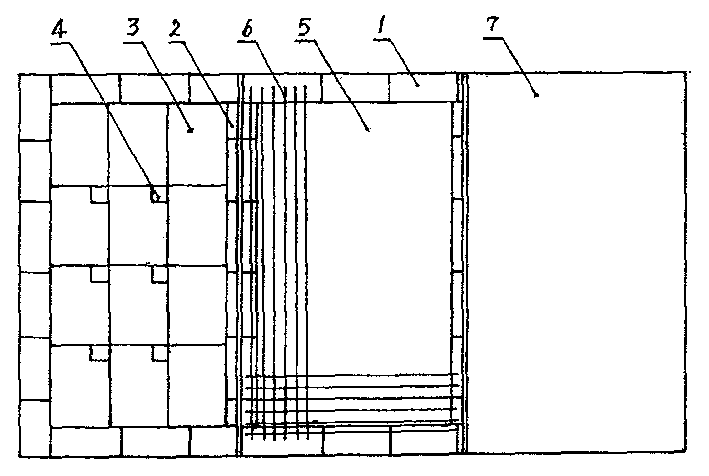

[0025] Such as figure 1 As shown, on the top floor of a house with an area of 300 square meters, a layer of cement mortar is first applied, and then a side brick 1 with a height of 0.06 meters and a width of 0.12 meters is laid with red bricks along the surrounding sides; The 0.12-meter partition brick 2 divides the roof into three long squares; the dense plastic foam board 3 is placed in the square; a small brick or cement with a height of 0.06 meters is placed in the reserved foam board gap The prefabricated block is used as support 4; a thick plastic film 5 is laid on the foamed plastic board in each square; 6mm steel bars are placed in units of each square; plas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com