Low-power-consumption high-voltage direct-current contactor

A high-voltage direct current, contactor technology, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of contactor product development requirements, high temperature rise, high power consumption, etc., to facilitate the promotion and implementation, reduce temperature The effect of increasing and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

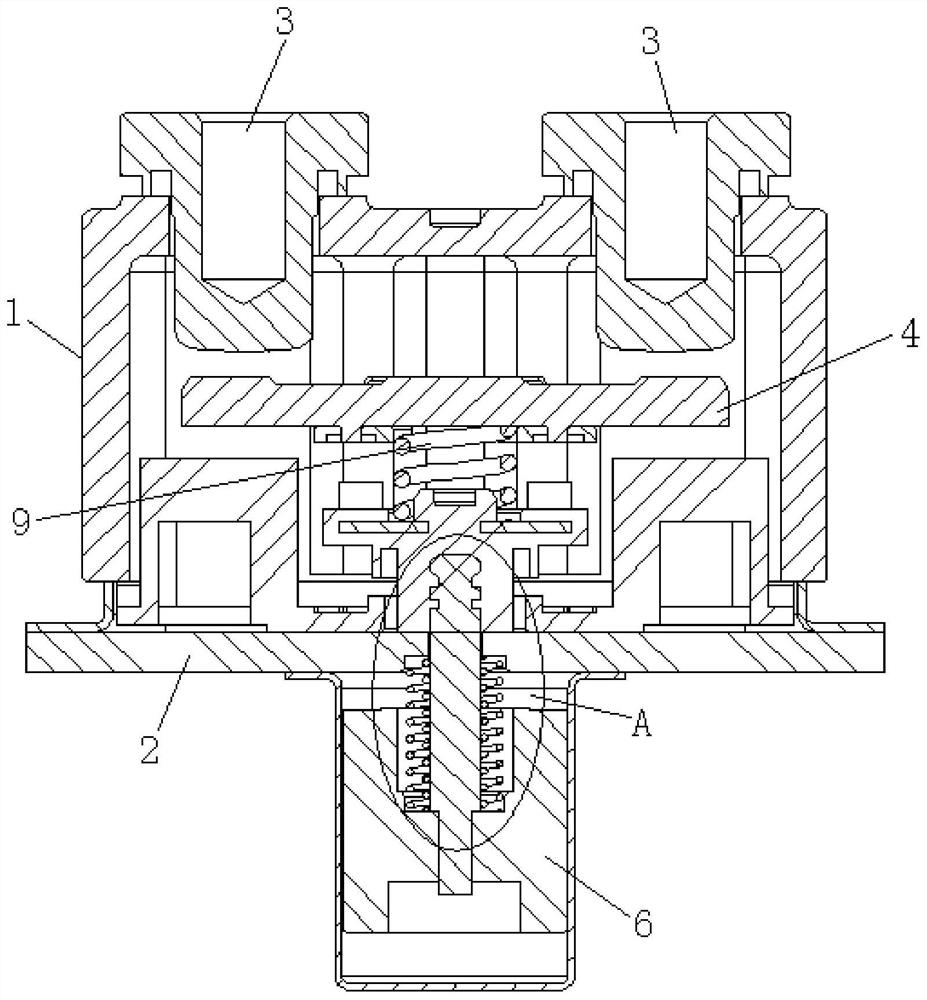

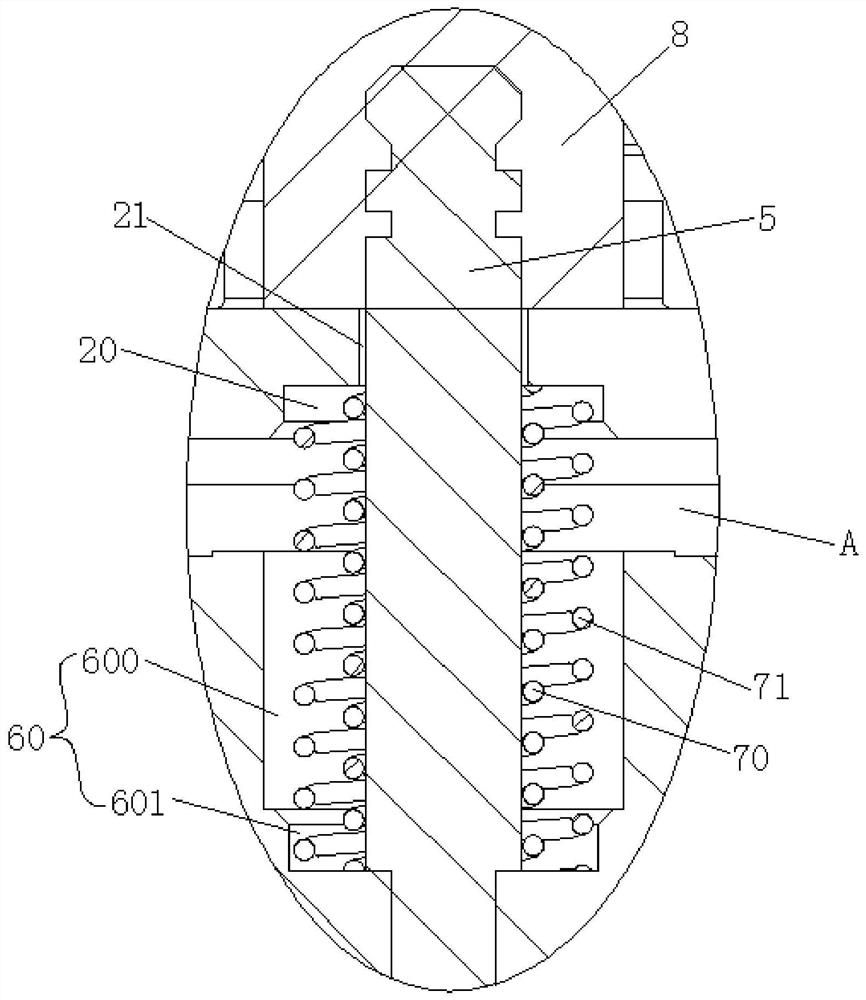

[0029] Please refer to the attached figure 1 and 2 Shown are the partial cross-sectional structure schematic diagram and the partial structure enlarged structural schematic diagram of the low-power high-voltage DC contactor of the present invention in the disconnected working state, respectively.

[0030] The low-power high-voltage DC contactor of the present invention includes a ceramic shell 1 with an open lower side, a magnetic pole plate 2 sealed and connected to the lower side of the ceramic shell 1, and two pole plates arranged side by side on the ceramic shell 1. The static contact point 3, a movable contact piece 4 built in the ceramic shell 1, and a vertically arranged push rod 5, wherein the dynamic contact piece 4 and the two static contact points 3 are respectively Arranged vertically relative to each other, the upper shaft end of the push rod 5 moves through the magnetic pole plate 2 and connects with the moving contact piece 4, and the lower shaft end of the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com