Method and apparatus for producing coil from piece of dough and separating sheet

A technology of spacer sheets and equipment, applied in the field of producing rolls made of dough sheets and spacer sheets, can solve problems such as inability to neatly fold and break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

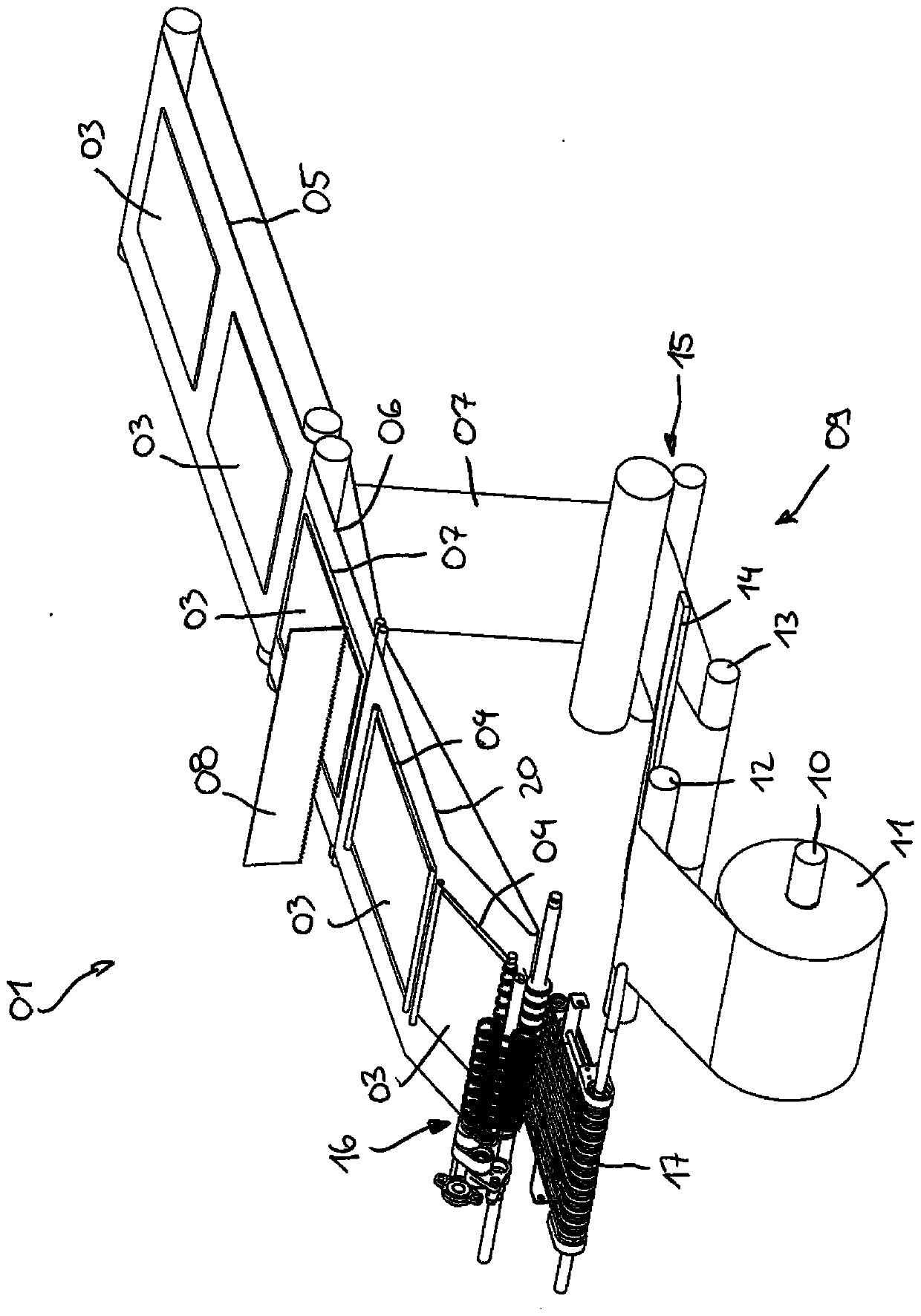

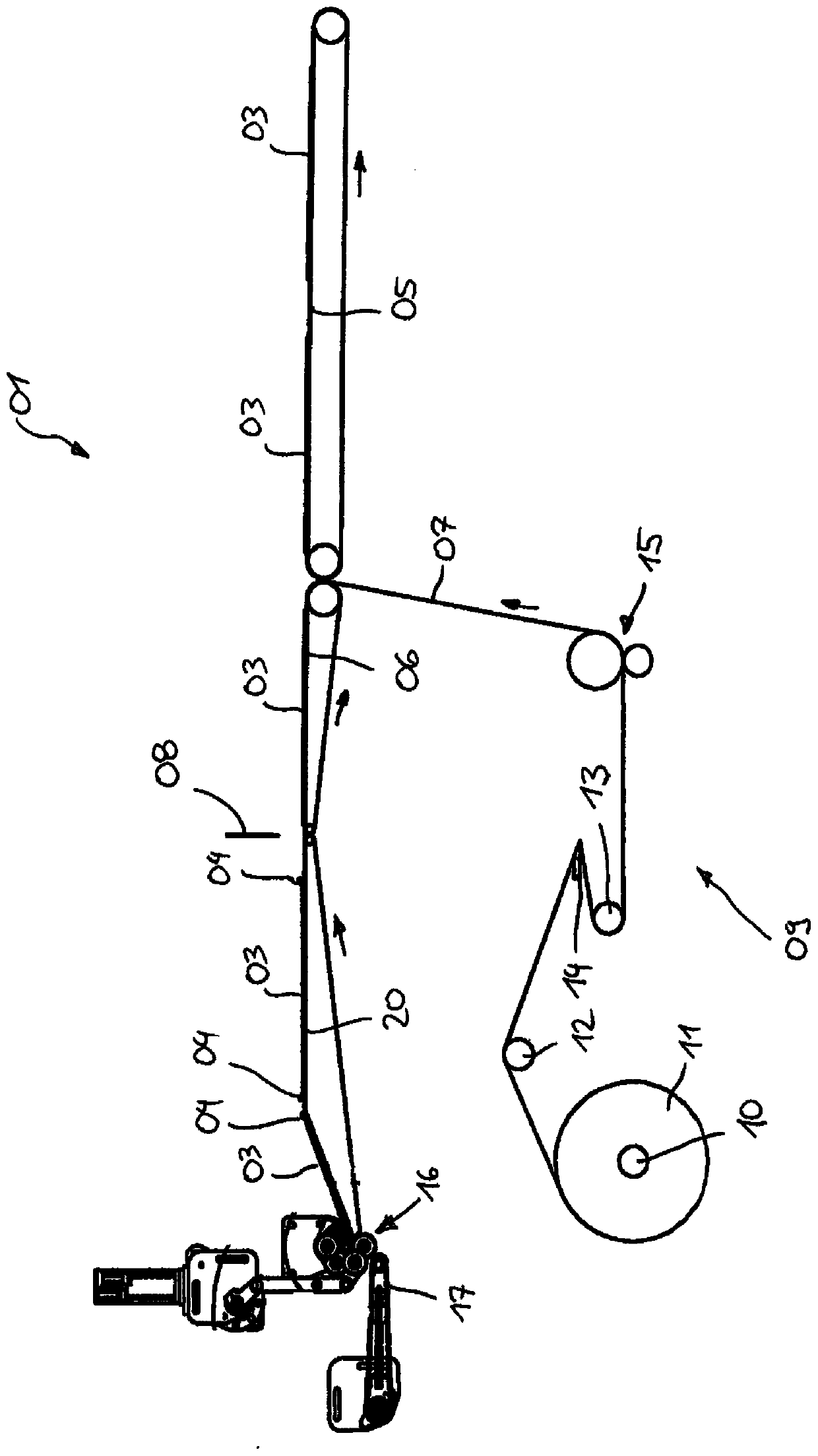

[0033] figure 1 Shown for production volume 02 (see Figure 10 ) of the device 01, each roll is made of a dough sheet 03 and a spacer sheet 04. Dough pieces 03 , which may be pizza dough or cake dough for example, have been conveyed by a conveying device 05 and then transferred to a feeding device 06 . In the feeding device 06 the dough sheet 03 is placed on a web of separator sheets 07 fed from below, which may be, for example, a baking paper material.

[0034] After the dough sheet 03 has been placed on the release sheet web 07, the release sheet web 07 is then cut to length by a cut-to-length device 08 which is formed like a strip knife to form the Separate sheet 04 for individual dough sheet 03.

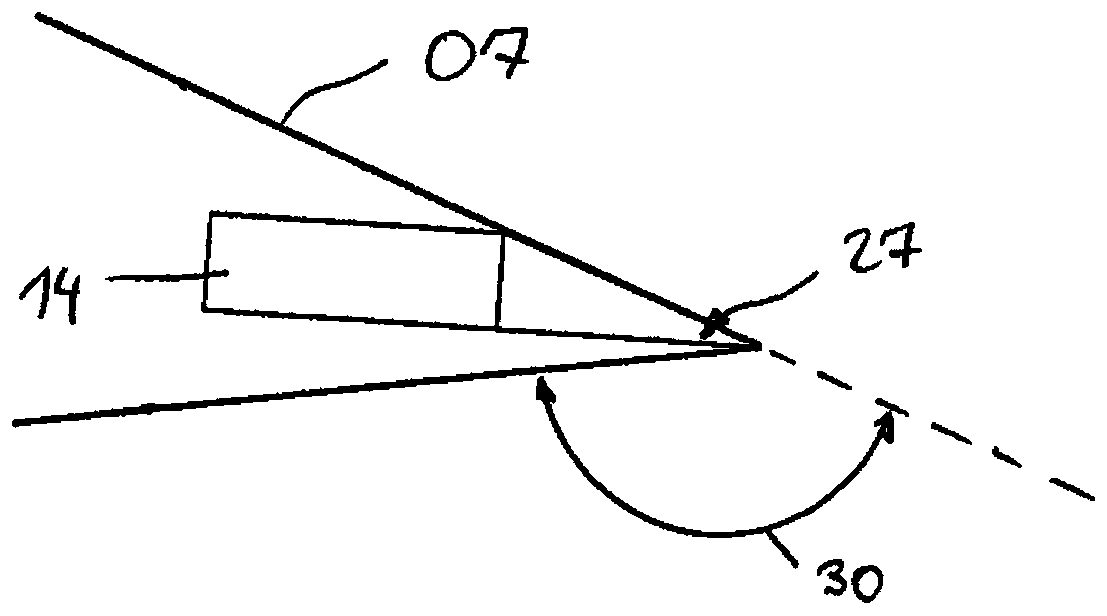

[0035] Before feeding the separator web 07 to the feeding device 06, said separator web 07 is deformed in the impact device 09, so that a predetermined residual stress state is produced in the separator web 07 in the conveying direction. The impact device 09 basically compris...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap