Glazed brick with fluorescent luster and preparation method thereof

A technique of polishing glazed tiles and luster, which is applied in the field of ceramic tiles, can solve the problems of lack of layers in products, and achieve the effect of strong layering, low Engler's viscosity, high uniformity and flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Polished glazed tiles with fluorescent luster include from bottom to top: green body layer, make-up soil layer, decorative layer, flashing layer, and glazed layer; the flashing layer contains mica flakes inside, and the mica flakes have fluorescent luster after firing. The flashing layer is composed of transparent glaze powder, water and mica flakes, and is composed of 100 parts of transparent glaze powder, 48 parts of water and 0.4 part of mica flakes by weight.

[0032] The particle size of the mica flakes is controlled according to the standard mesh number, and the mesh number is 15-30 mesh.

[0033] The mica sheet includes micas of two different colors, phlogopite and silver mica, and the composition of phlogopite and silver mica by weight is 40 parts of phlogopite and 60 parts of silver mica.

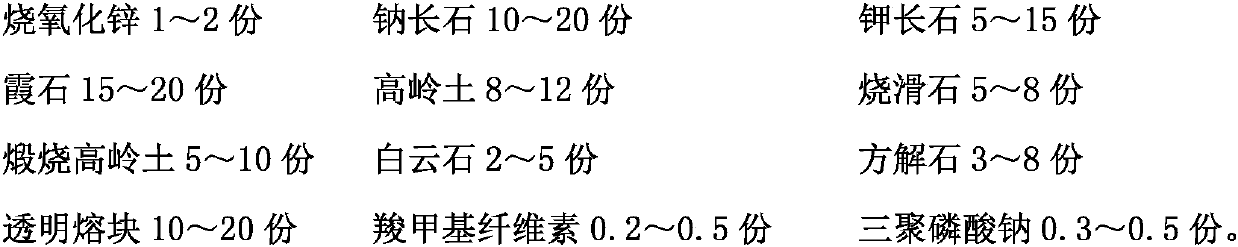

[0034] The weight composition of the transparent glaze powder of the flashing layer is: 1 part of burnt zinc oxide, 13 parts of albite, 15 parts of potassium feldspar, 16 pa...

Embodiment 2

[0045] Polished glazed tiles with fluorescent luster include from bottom to top: body layer, makeup soil layer, decorative layer, flashing layer, and glazed layer. Wherein the flash layer contains mica flakes inside, and the mica flakes have fluorescent luster after firing. The flashing layer is composed of transparent glaze powder, water and mica flakes, and is composed of 100 parts of transparent glaze powder, 48 parts of water and 0.8 part of mica flakes by weight.

[0046] The particle size of the mica sheet is controlled according to the standard mesh number, and the mesh number is 30-50 mesh.

[0047] Described mica sheet comprises phlogopite, silver mica, yellow mica, muscovite totally 4 kinds of micas of different colors, and phlogopite, silver mica, yellow mica and muscovite are made up of phlogopite 25 parts, silver mica 30 parts, yellow mica by weight. 10 parts of mica, 35 parts of muscovite.

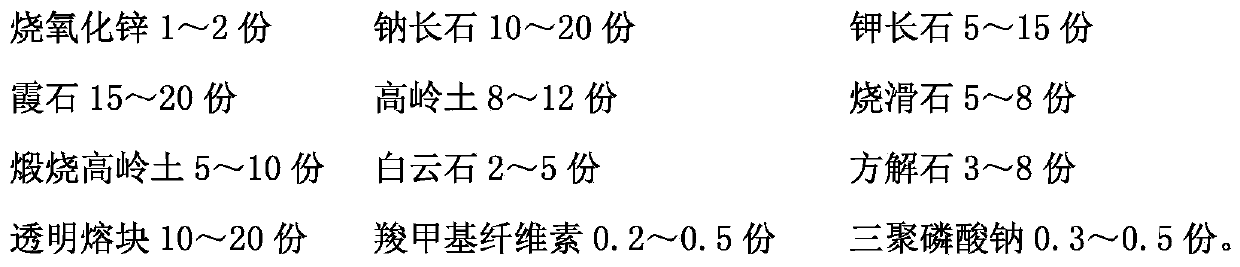

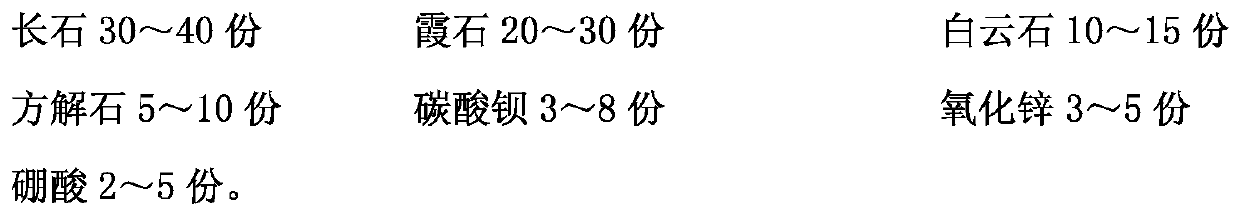

[0048] The weight composition of the transparent glaze powder of the f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap