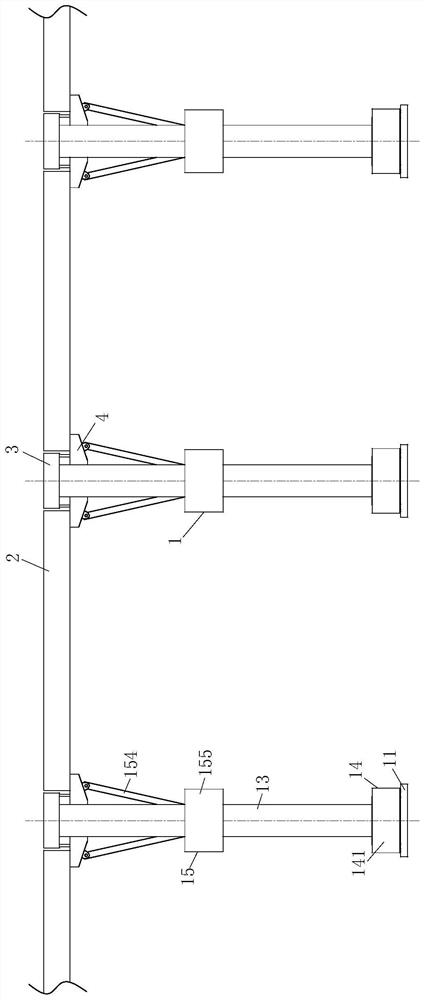

A quick and early demolition support for construction engineering

It is a construction engineering and fast technology, which is applied in the direction of construction, building structure, and preparation of building components on site. It can solve the problems of easy toppling of steel supports, waste of manpower, and difficulty in disassembly and assembly, so as to avoid shaking, increase speed, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

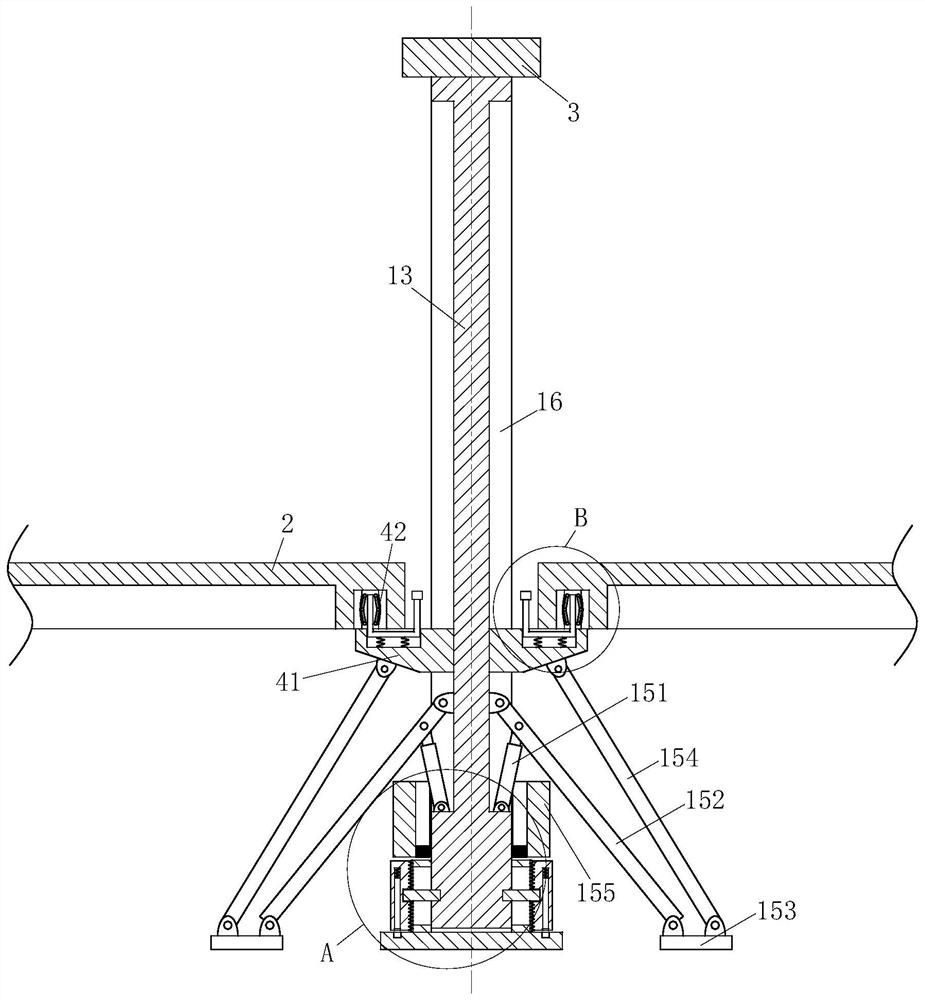

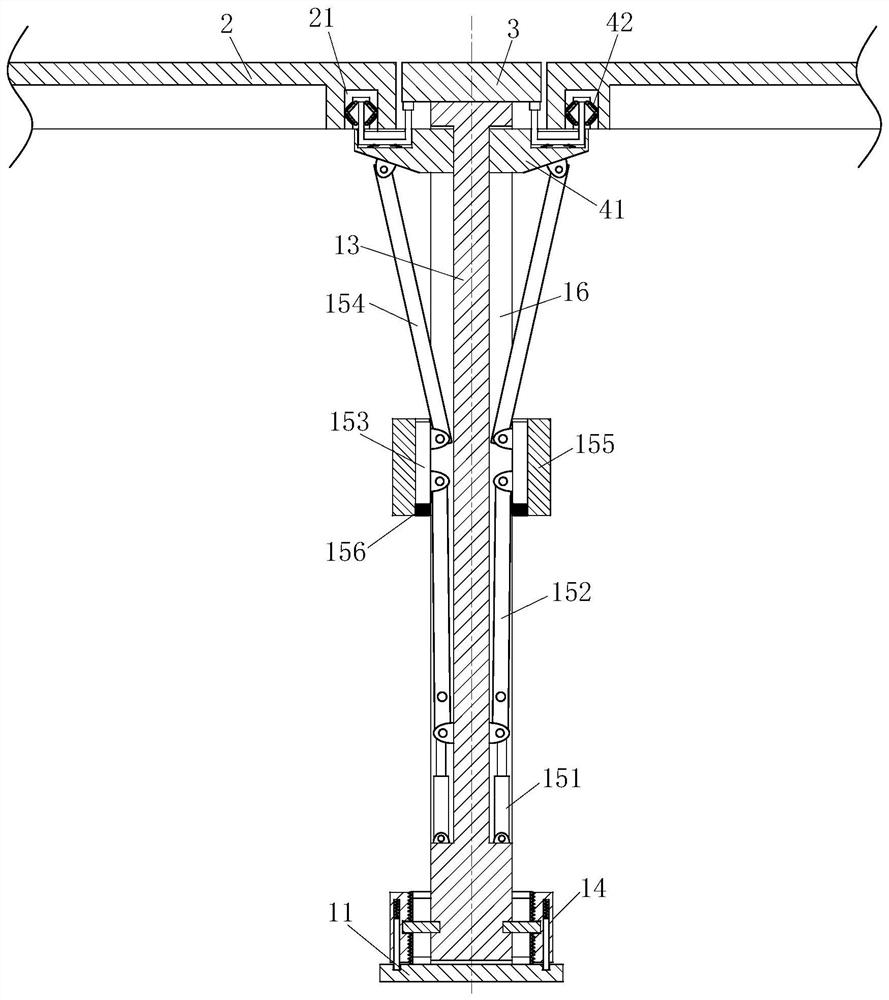

[0026] As an embodiment of the present invention, the lifting mechanism 15 includes an electric push rod 151, a No. 1 articulated rod 152, a support plate 153, a No. 2 articulated rod 154, a protective sleeve 155 and a magnet 156; the electric push rod 151 One end of one end is hinged on the bottom wall of the strip chute 16, and the other end of the electric push rod 151 is connected to the No. 1 articulated rod 152 through the rotation of the rotating shaft, and the electric push rod 151 is used to push the No. 1 articulated rod 152 to rotate; One end of No. articulated rod 152 is hinged on the sidewall of strip chute 16, and the other end of No. 1 hinged rod 152 is hinged on the upper side of support plate 153; Described support plate 153 is used for being supported on the ground, and support plate 153 It is an iron product; one end of the No. 2 articulated rod 154 is hinged to the upper side of the support plate 153, and the other end is hinged to the early dismantling head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com