Lifting upright post with rolling assemblies

A technology of lifting columns and rolling parts, which is applied to the connection of rods, connecting components, mechanical equipment, etc., which can solve the problems of unsmooth lifting of the inner tube, jamming, and increased resistance of the inner tube, so as to achieve simple structure and prevent mutual wear , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

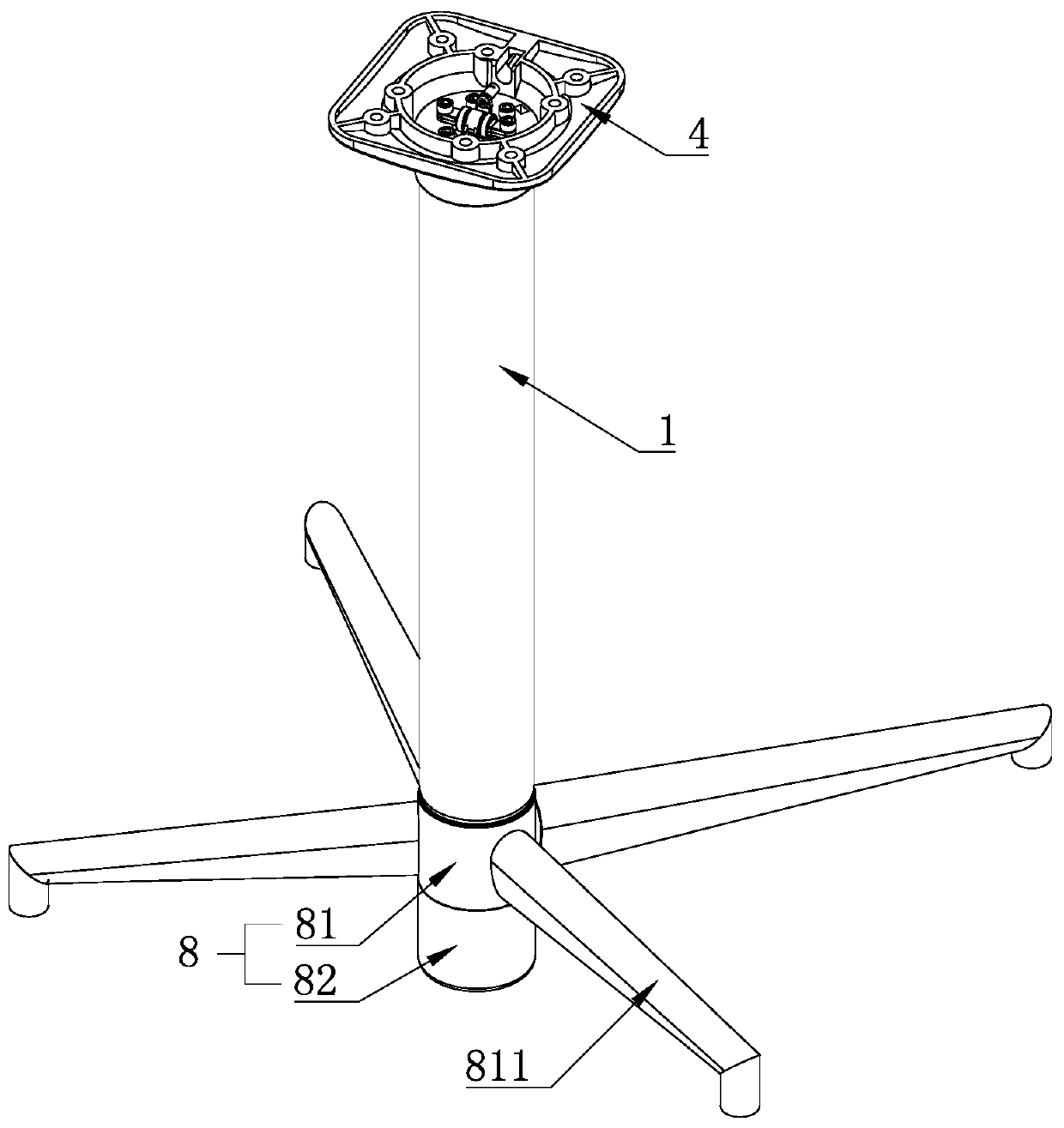

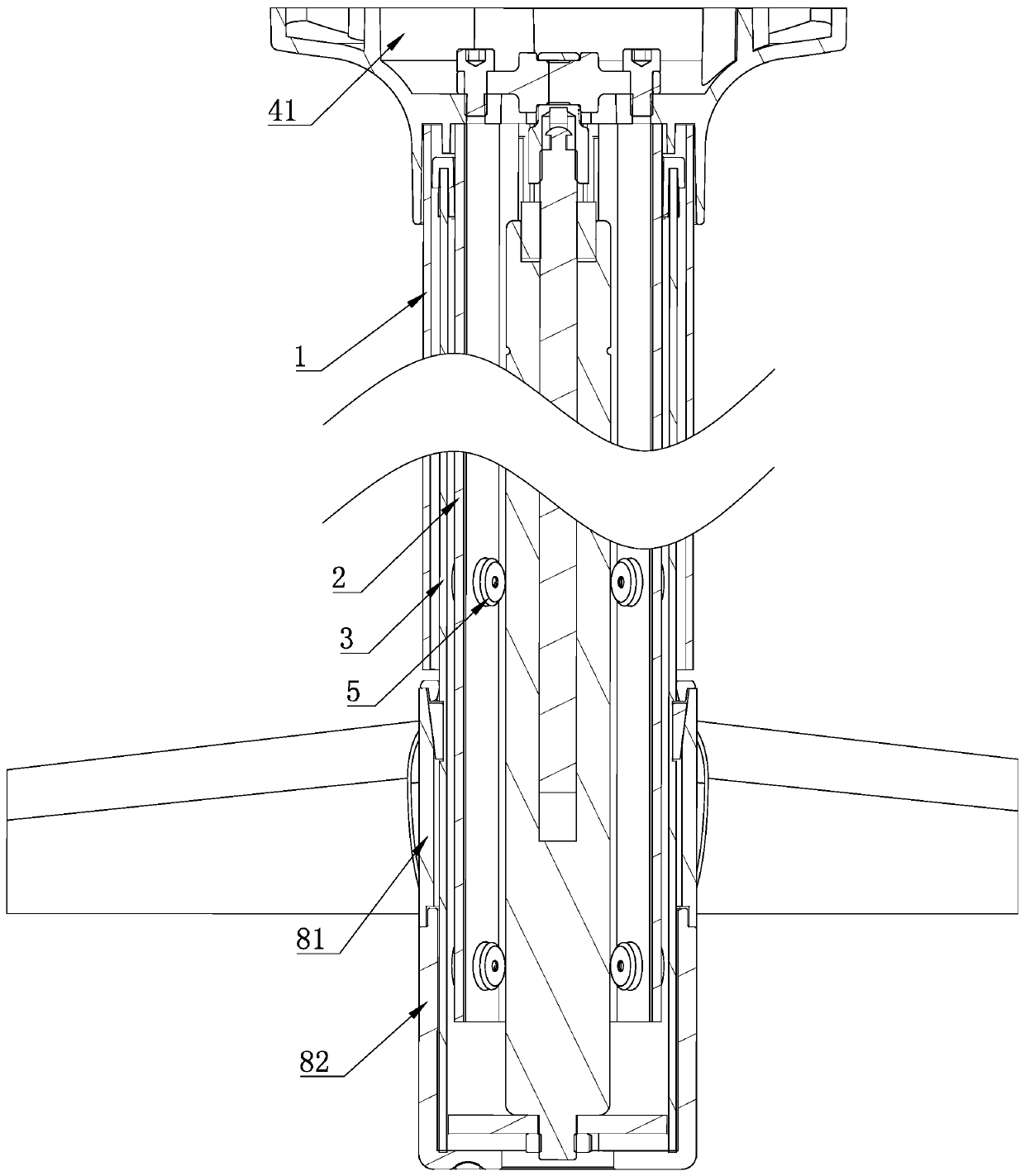

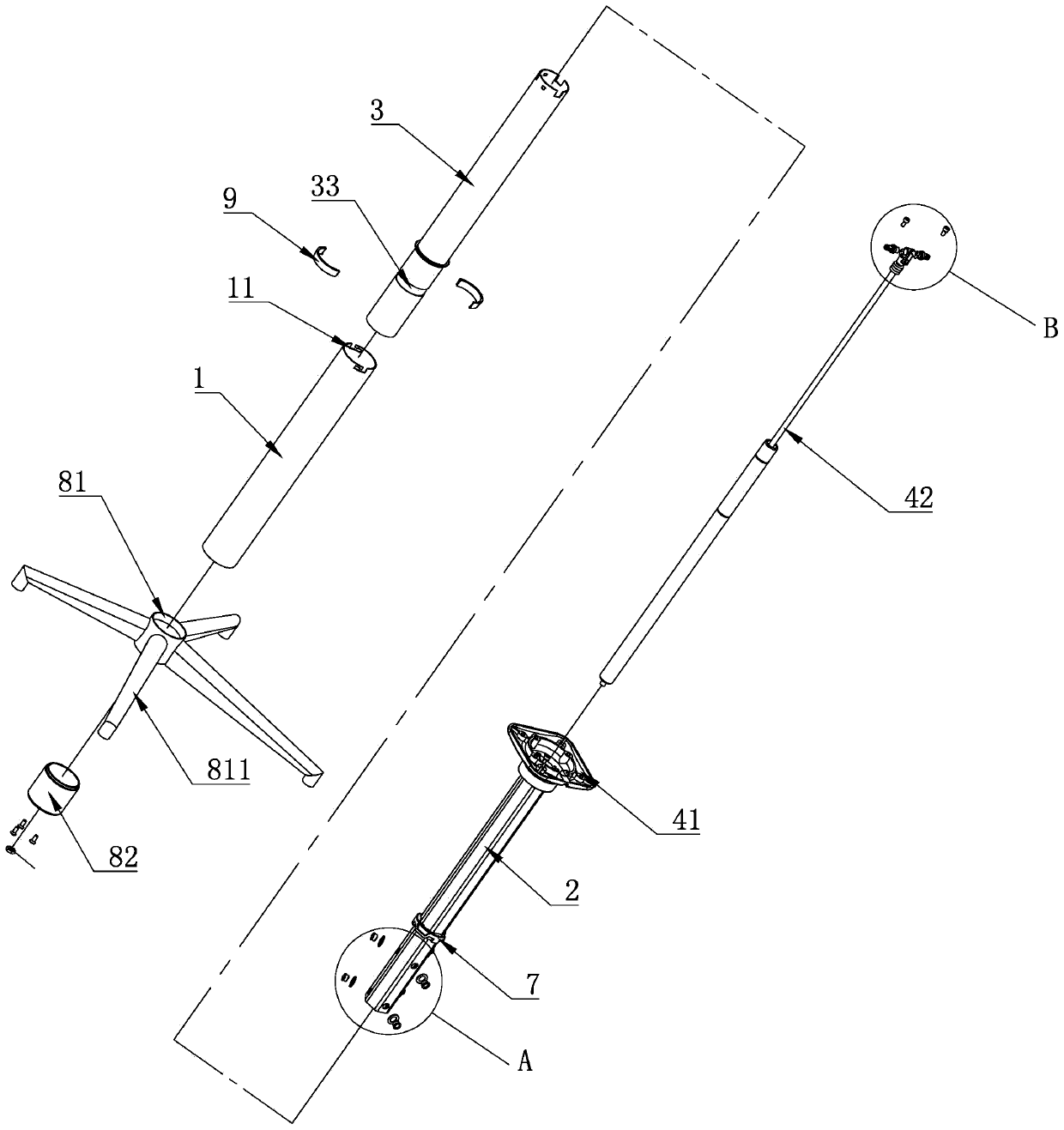

[0036] A lifting column with a rolling assembly, comprising an inner tube 2, an outer tube 3 sleeved outside the inner tube 2, a sleeve sleeve 1 sleeved outside the outer tube 3 to protect the inner tube 2 during lifting, and a sleeve sleeved on the outer tube The lifting base 8 at the bottom of 3 and the lifting assembly 4 that drives the inner tube 2 to lift up and down, the inner tube 2 and the outer tube 3 are slidably connected.

[0037]Between the inner tube 2 and the outer tube 3, there are at least two rolling assemblies 5 that prevent the inner tube 2 from shaking. In this embodiment, the inner tube 2 is preferably formed by a plurality of side walls, and the cross section of the inner tube 2 is polygonal. It is preferably hexagonal, and at least one installation hole is provided on the six side walls of the inner tube 2, and a rolling assembly 5 is respectively provided in each installation hole, and the rolling assembly 5 includes a base inserted on the inner tube 2 ...

Embodiment 2

[0042] The difference between the present embodiment and the first embodiment is that the base 51 and the adjusting gasket 6 are integrated, and the adjusting gasket 6 is in contact with the outer wall of the inner tube 2 . In this embodiment, the adjusting gasket 6 and the base 51 are arranged as an integral structure, and the base 51 of the adjusting gasket 6 with different thicknesses is selected according to the gap between the inner tube 2 and the outer tube 3, so that no matter whether the inner tube 2 or the outer tube What is the gap between 3? Each rolling assembly 5 always presses the inner wall of the outer tube 3 to prevent the rolling assembly 5 from moving between the inner tube 2 and the outer tube 3. At the same time, the rolling assembly 5 forms a support for the inner tube 2 to prevent The inner tube 2 shakes during the lifting process, and the integrated adjustment gasket 6 and base 51 make it unnecessary to assemble the adjustment gasket 6 and the base 51 du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com