Two-dimensional pre-stressing applying device and working method thereof

A technology of applying device and pre-stress, applied in the direction of measuring device, measuring force, instrument, etc., to solve the calibration problem and solve the effect of residual stress accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

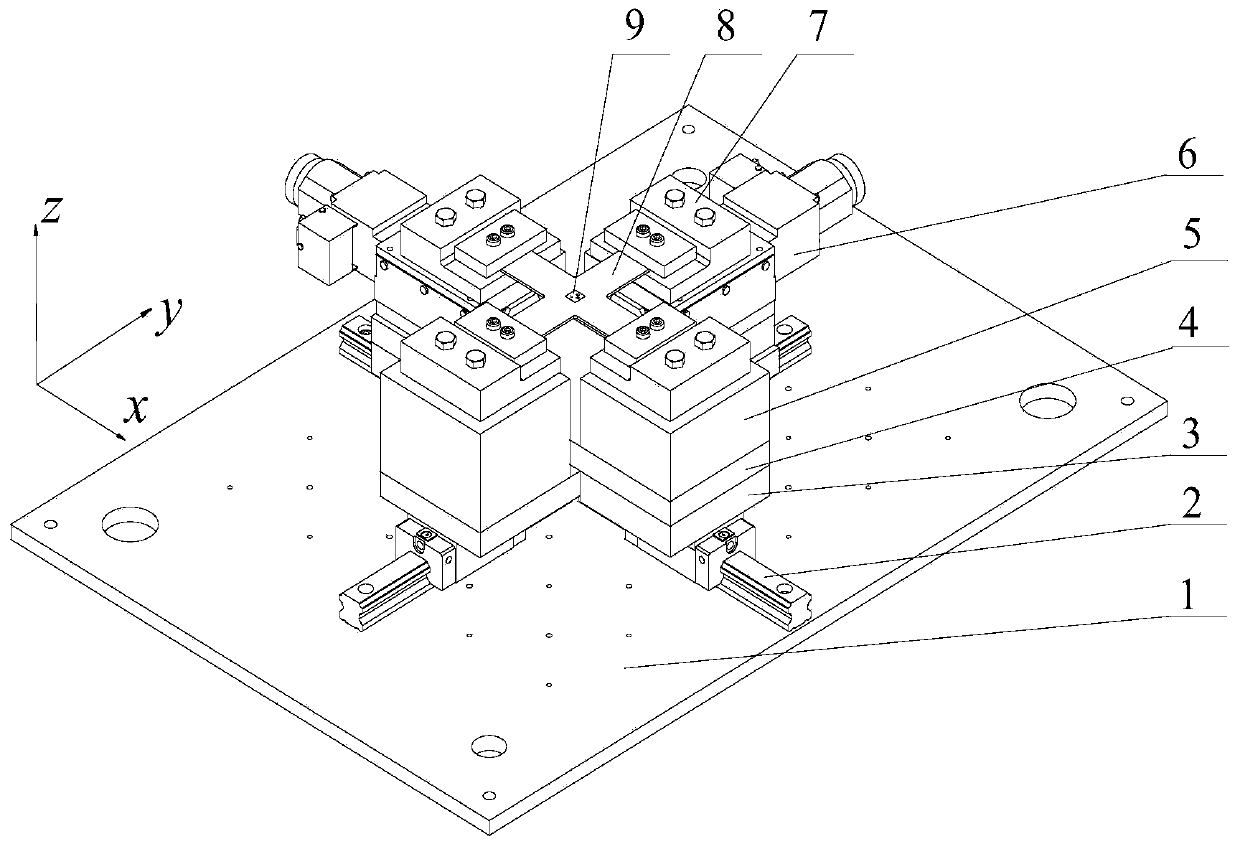

[0022] Such as figure 1 Shown is a two-dimensional prestressing device, including a workbench 1, two linear sliding modules 2 vertically intersecting on the workbench 1, and a cross sample 8;

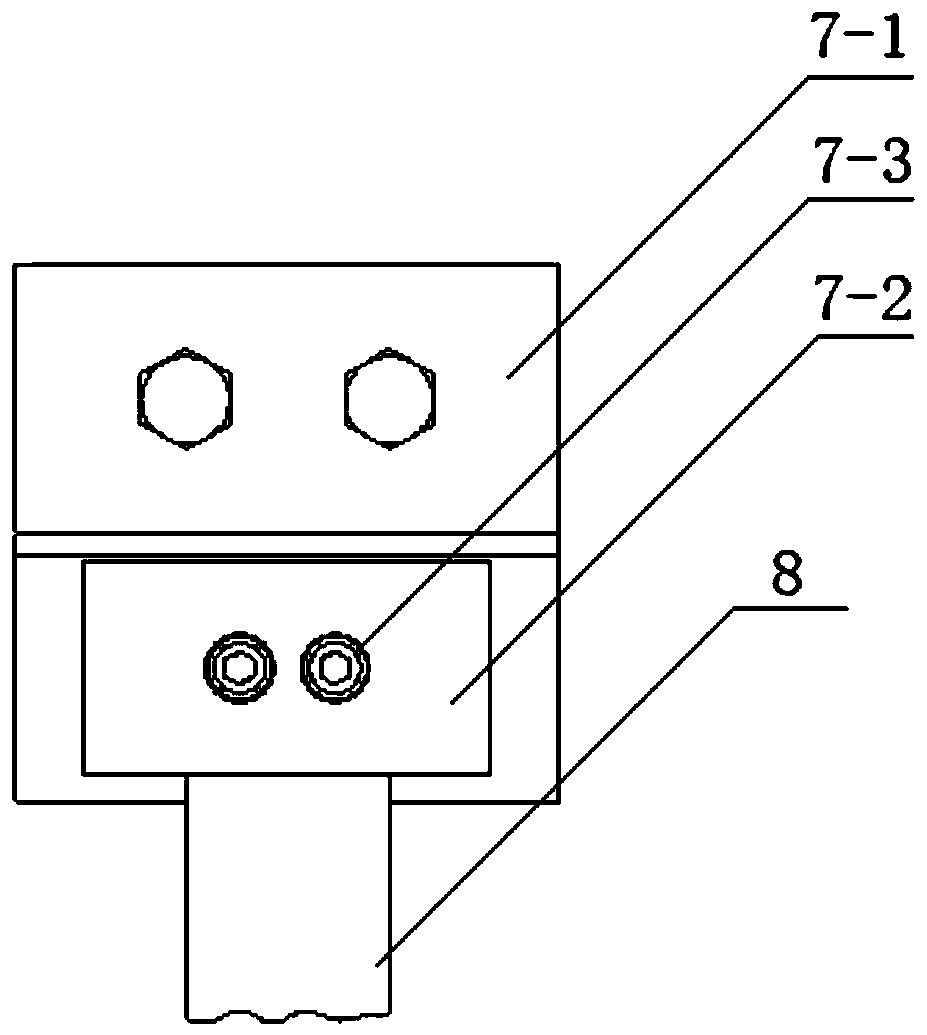

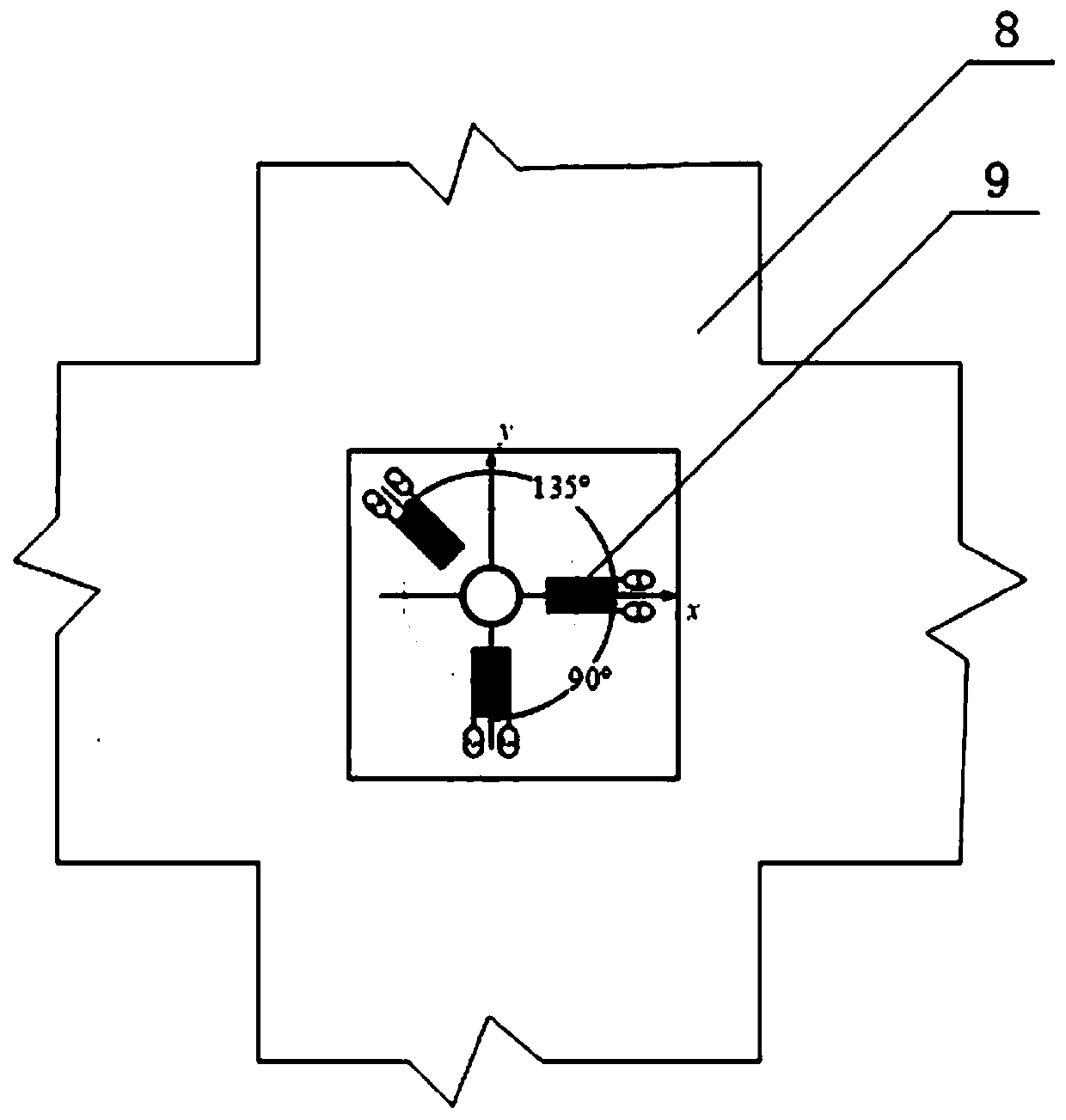

[0023] Wherein, the linear sliding module 2 includes a linear guide rail, two guide rail sliders adapted to the linear guide rail, and a connecting base plate 4 installed on the two guide rail sliders, and the two guide rail sliders are symmetrically distributed on the connecting base plate 4; the connecting bottom plates 4 on the two linear sliding modules 2 are vertically staggered up and down through the pads 3, and slide along their respective linear guide rails independently of each other; the two ends of the connecting bottom plates 4 are respectively installed with The electric platform 6 and the fixed platform 5 are respectively provided with sample clam...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap