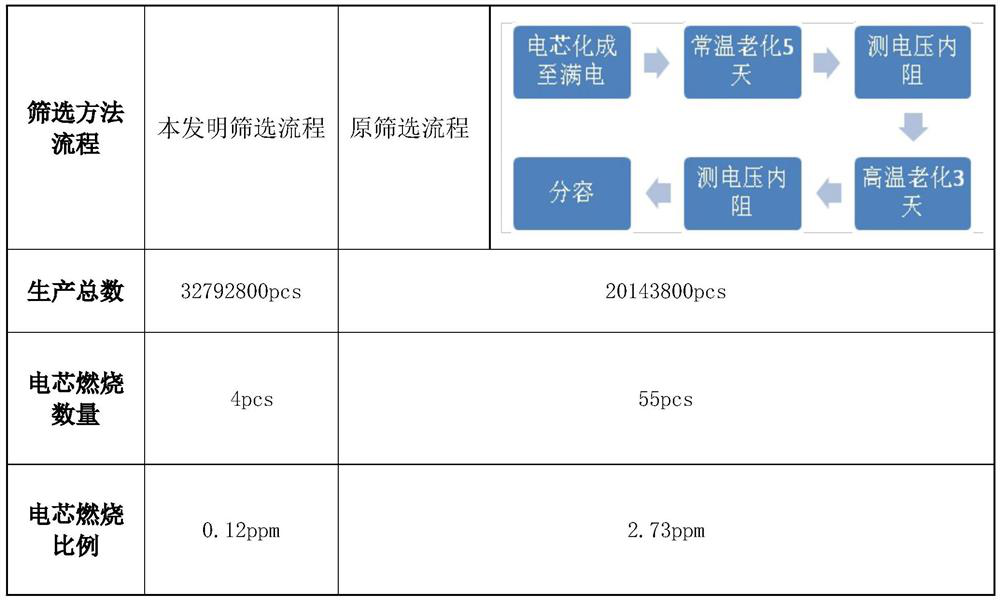

A screening method for lithium-ion battery cells based on a thermal imager

A lithium-ion battery, thermal imager technology, used in sorting and other directions, can solve problems such as threats to personal and property safety, combustion and even explosion, and achieve the effect of improving product quality and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

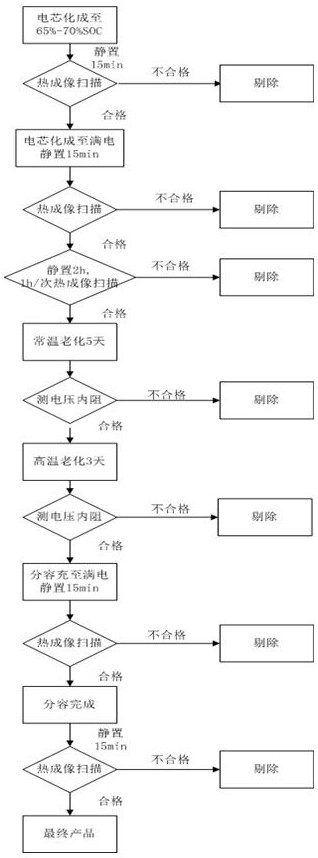

[0028] A kind of screening method based on the lithium-ion battery cell of thermal imager, it comprises the steps:

[0029] S1: Put the activated battery on the forming cabinet, after forming and charging to 65%-75% SOC, let it stand on the forming cabinet for 15±1min;

[0030] S2: Use the thermal imager to scan the battery cell, and judge whether the battery cell is normal through the color difference displayed on the thermal imager. The abnormal cell is bright yellow, and the normal cell is dark red. If it is normal, enter S3. Abnormal Then enter S14;

[0031] S3: Turn the normal battery in S2 into full charge and let it stand for 15±1min;

[0032] S4: Repeat S2 to judge whether the battery is normal, if normal, enter S5, and if abnormal, enter S14;

[0033] S5: After the formation is completed, put the battery cells into the material tank, lay it flat and let it stand for 2 hours, and remove the abnormal batteries every 1 hour / time of thermal imaging scan, if it is normal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com