Manual adjusting mechanism for automobile seat side wing width

A car seat, manual adjustment technology, applied in vehicle seats, vehicle parts, special positions of vehicles, etc., can solve the problems of reduced user constraints, inability to adjust the width of the flanks, and users easily leaving the seat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

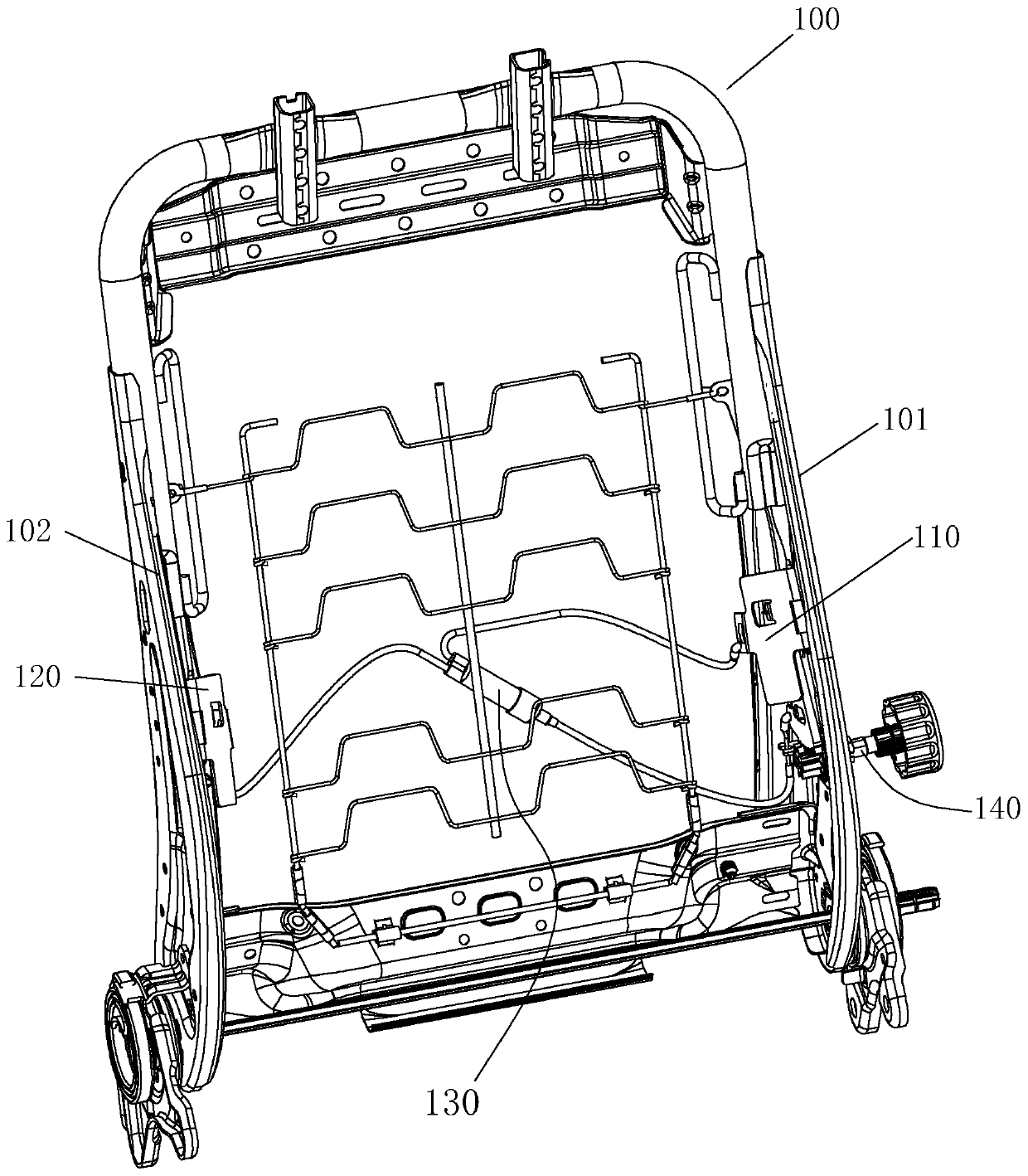

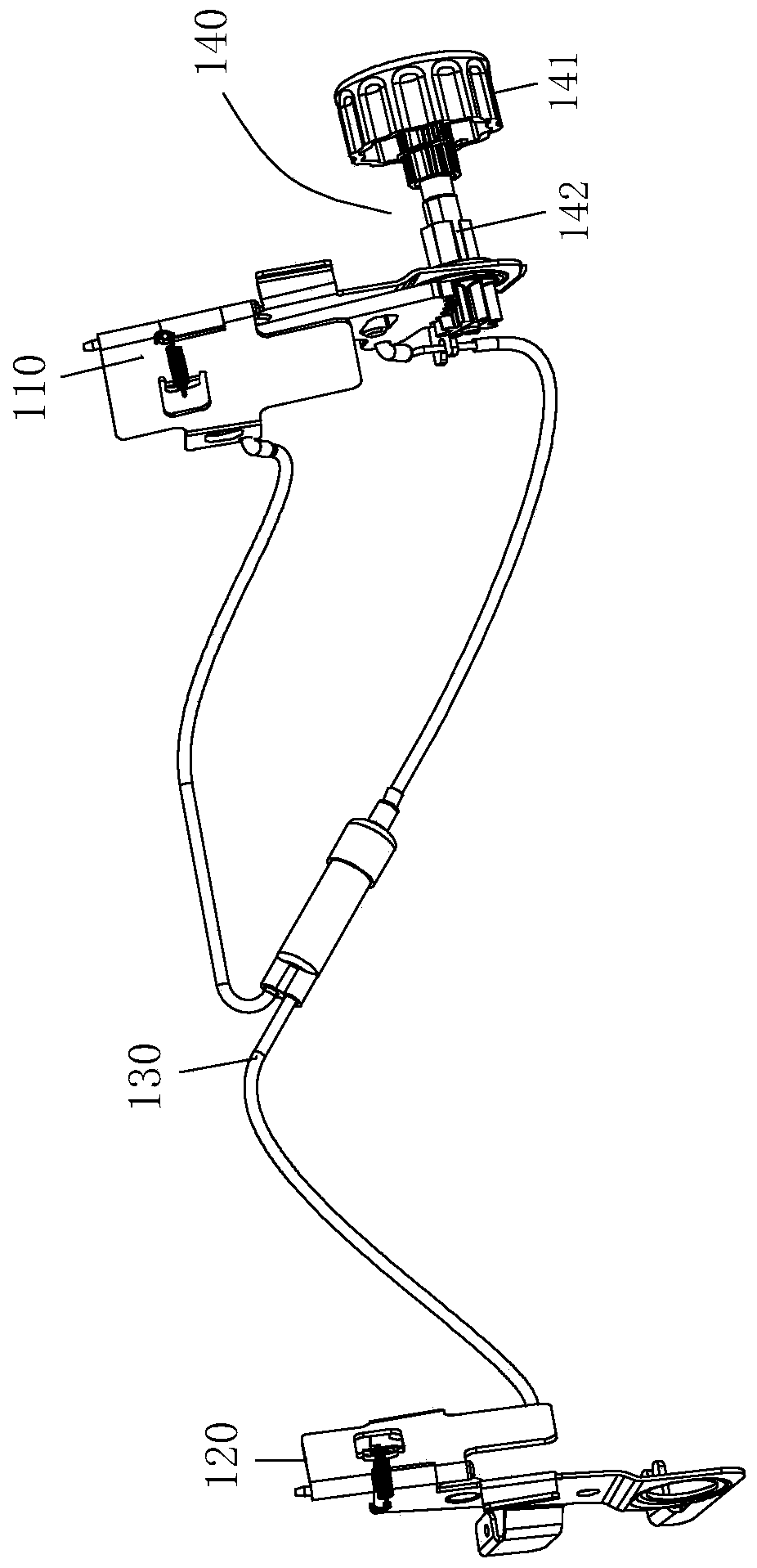

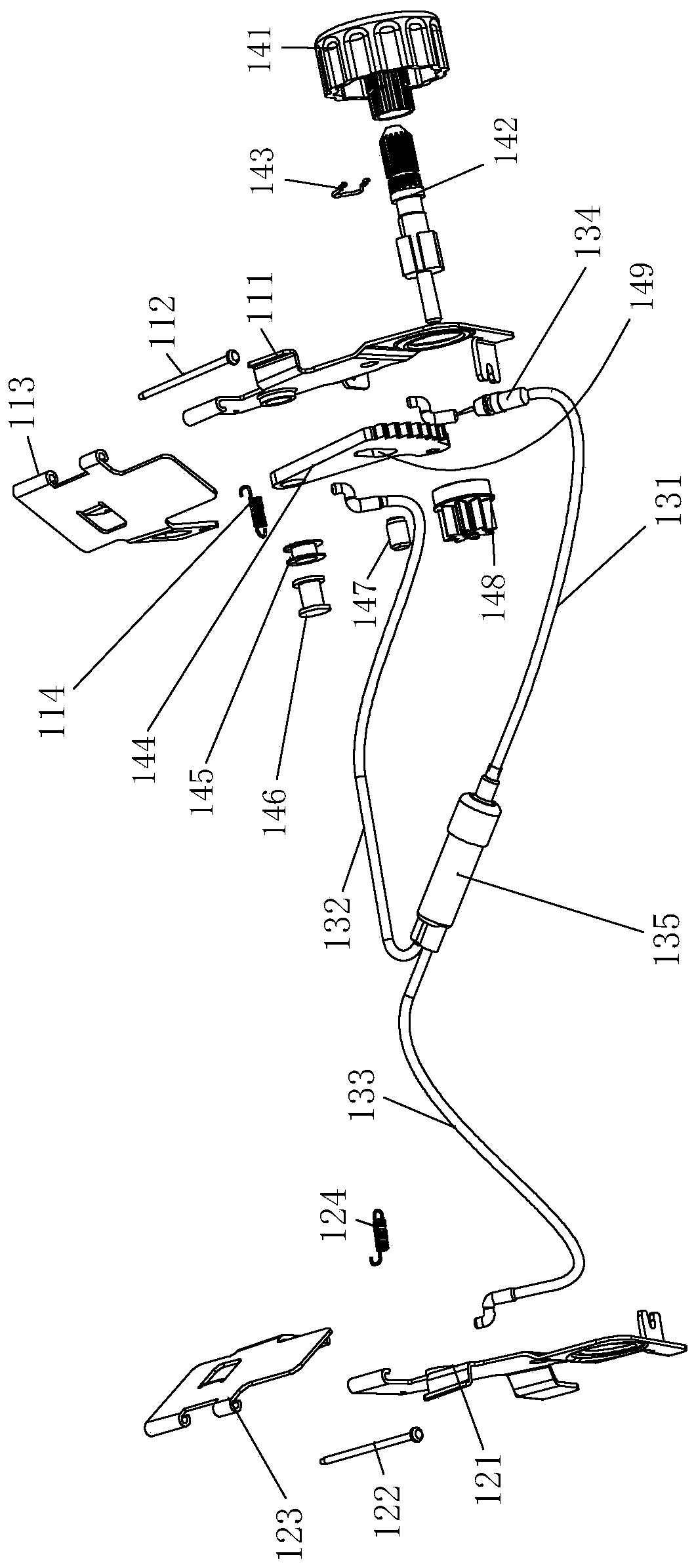

[0024] like Figure 1 to Figure 4 The shown car seat side wing width manual adjustment mechanism includes a left adjustment mechanism assembly 110, a right adjustment mechanism assembly 120, a cable assembly 130 and a manual drive assembly 140; the left adjustment mechanism assembly 110 and the seat frame 100 The left side panel of the seat frame 100 is connected and in contact with the left wing of the seat, the right adjustment mechanism assembly 120 is connected with the right side panel of the seat frame 100 and is in contact with the right side wing of the seat, the left adjustment mechanism assembly 110 and the right adjustment mechanism assembly 120 are also all connected with the drag cable assembly 130; the manual drive assembly 140 is installed on the left adjustment mechanism assembly 110, and the manual drive assembly 140 is connected with the drag cable assembly 130 to be able to pull The drag cable assembly 130 moves, thereby driving the left adjustment mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com