Supporting structure of conveying module and conveying module

A conveying module and supporting structure technology, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of easy occurrence of jams or retention, unreasonable support structures, etc., to prevent jams and reduce the occupation. The effect of land area and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

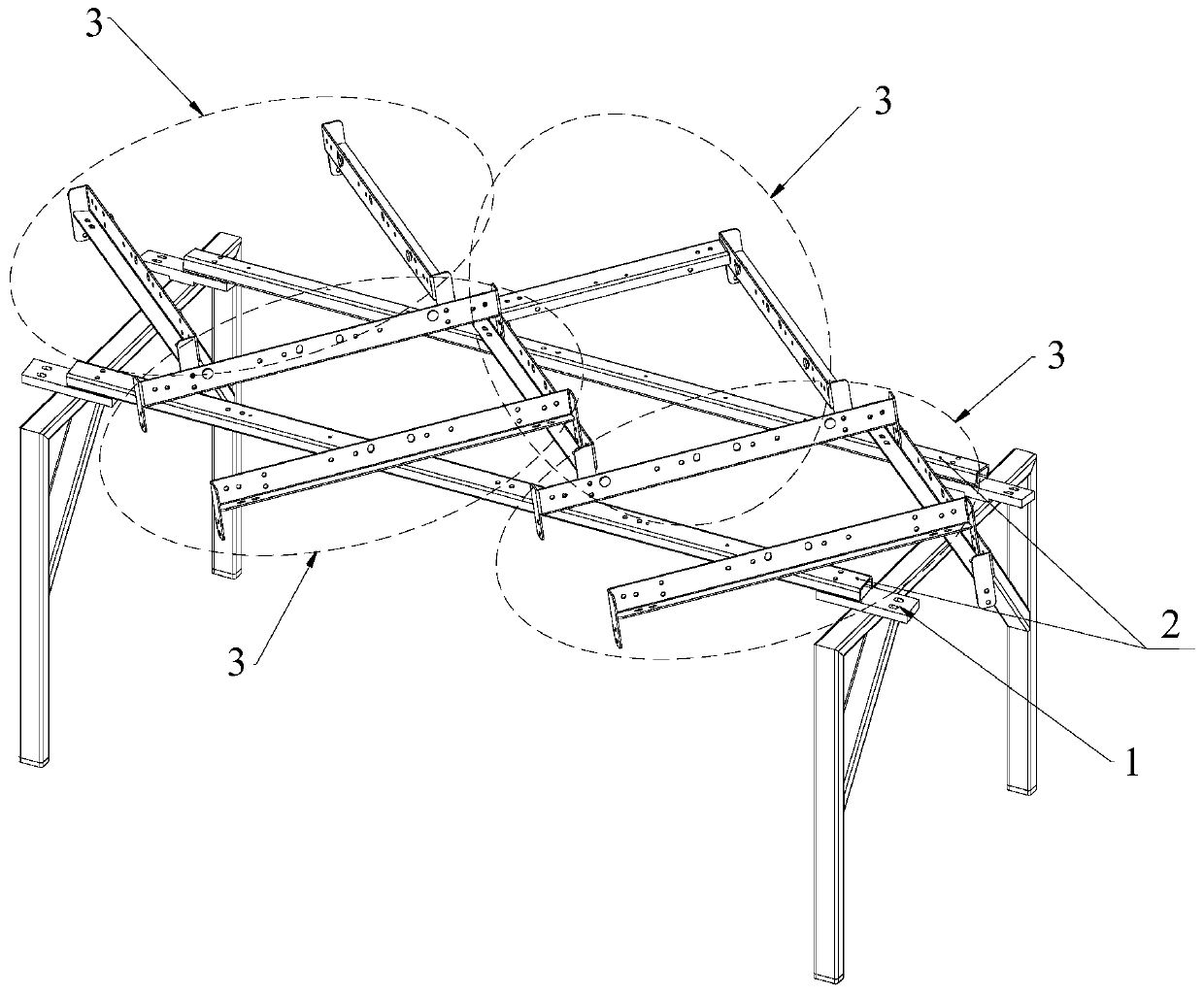

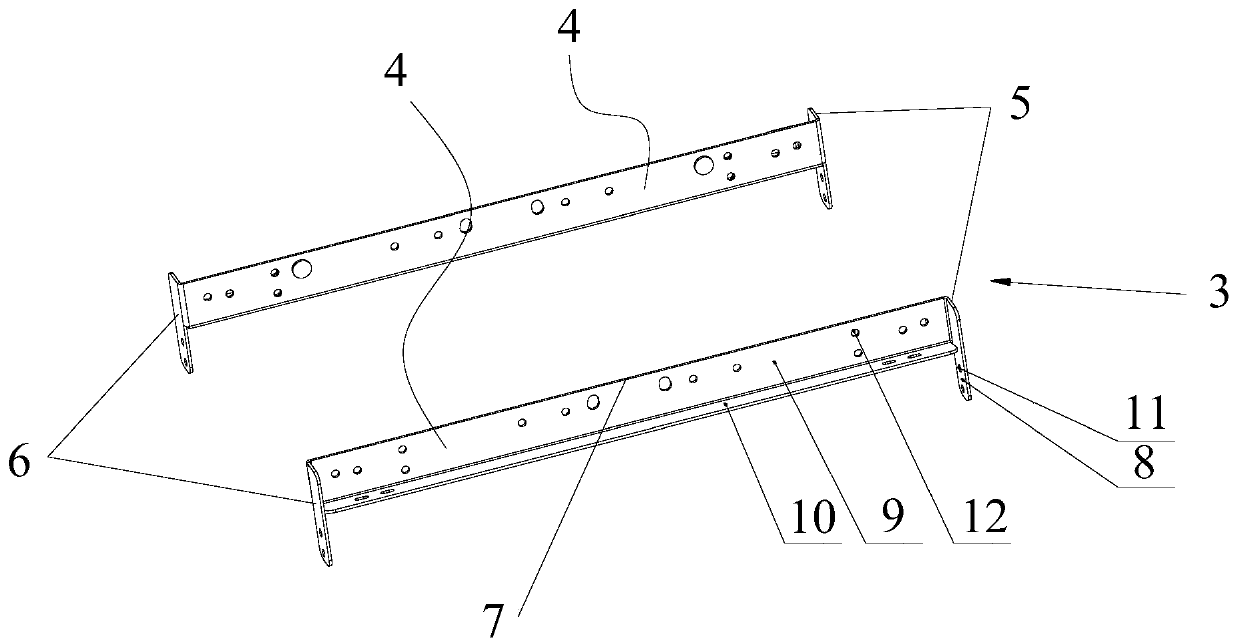

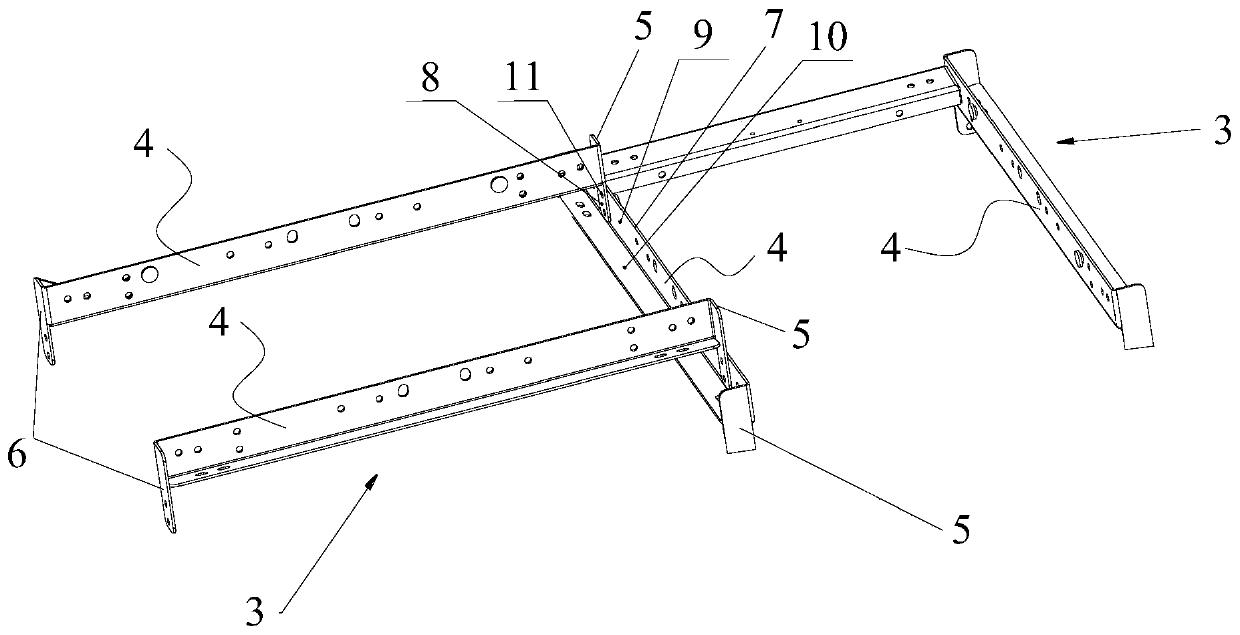

[0036] Such as Figure 4 and 5 As shown, this embodiment discloses a delivery module, including a support structure and a plurality of delivery units 14, each delivery unit 14 is installed on a corresponding fixed bracket 3; each delivery unit 14 cooperates sequentially, and the output of the previous delivery unit 14 The end 15 is docked with the input end 16 of the latter conveying unit 14, and the sorting end 17 of the conveying unit 14 is used for docking with the external package module 18. The conveying unit 14 includes a transmission mechanism and a drive mechanism, and the transmission mechanism is driven by the drive mechanism. The goods can be conveyed in two directions towards the output end 15 and the sorting end 17.

[0037] The conveying module itself of the present application is used as a conveying line for conveying the goods to be sorted to the corresponding packing module 18. It does not need a circular track, reduces the floor space, reduces the cost, and ...

Embodiment 2

[0051] Such as Figure 8 As shown, this embodiment discloses a sorting device, including a bag-up module 26, a bag-collecting module 18, a conveying module, an identification module and a controller, and the conveying module is the conveying module mentioned in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com