Large-span step-by-step cantilevered diagonal bracing structure and its construction method based on pull-up and bottom-embedded structures

A diagonal bracing and cantilever technology, applied in the direction of house structure support, house structure support, building structure, etc., can solve the problems of complex structure and difficult construction, increase the utilization rate of indoor space, and meet the requirements of structural safety and load. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

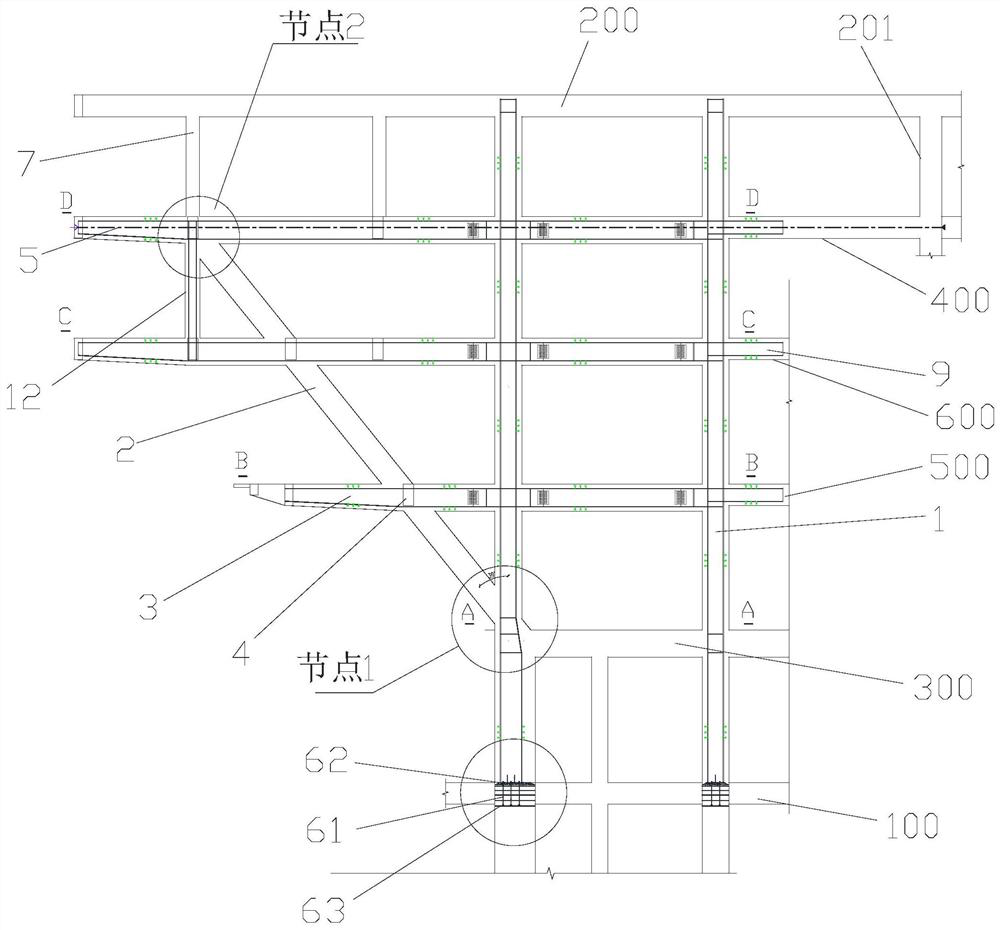

[0055] Please see attached figure 1 , the architectural shape is a warship, implying to go forward bravely. The building height is 22m. In order to ensure the large inclination angle of the front and rear of the warship, the cantilever of the second floor relative to the first floor is 8.9m, and the cantilever of the third and fourth floors is 15.6m relative to the first floor.

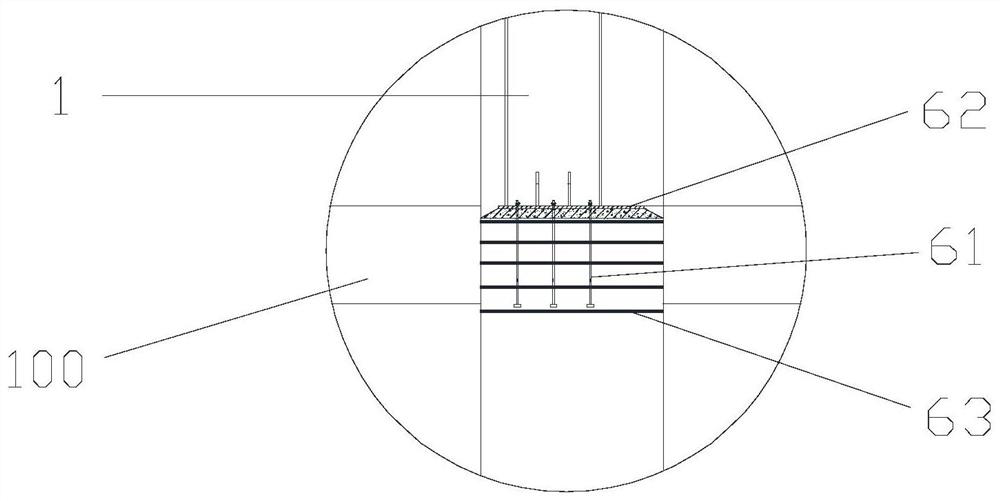

[0056] Please see attached figure 2 , all loaded steel columns 1 fall on the embedded part of the negative floor 100, and the embedded joints are anchored by 6M32 and 4M30 high-strength anchor bolts 61, embedded slabs 62 and the structure of the negative floor 100 to support the upper eccentric load. The floating grout at the horizontal construction joints must be chiseled out, and high-strength grouting materials are used to fill the joints under the pre-embedded slab 62 so that no gaps are left and the structural integrity is ensured.

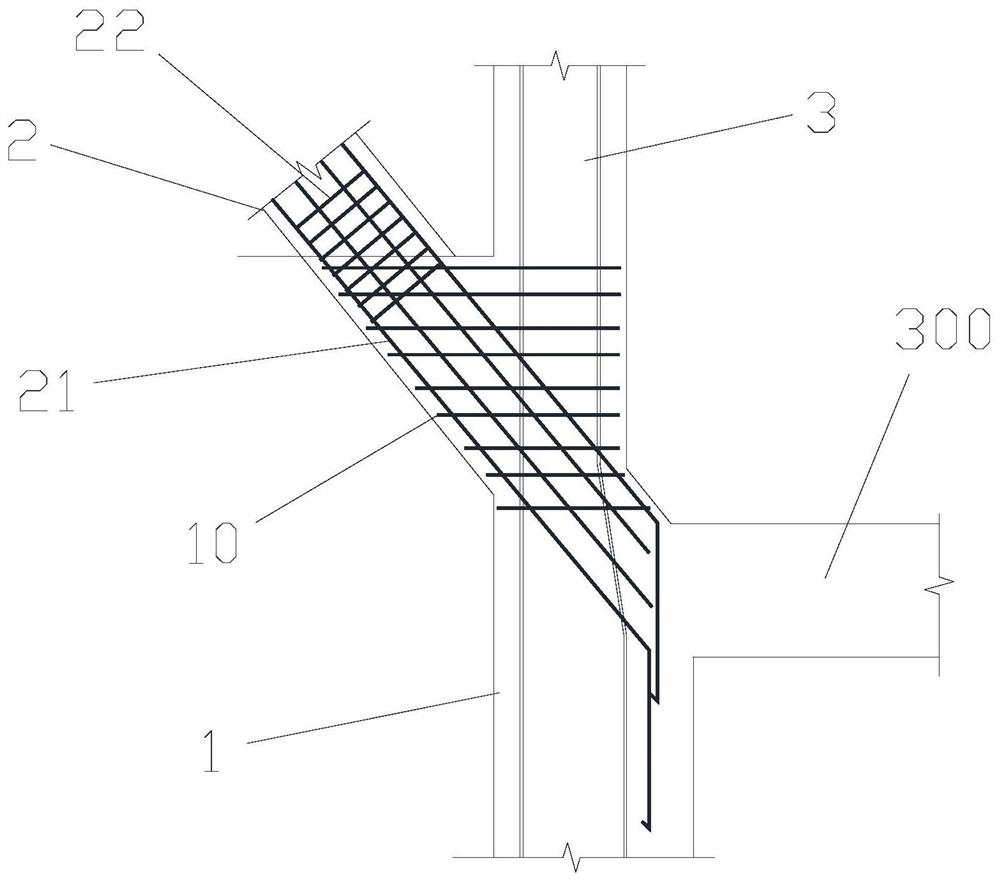

[0057] Please see attached image 3 And attached Figure 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com