A car door lock connection structure and its auxiliary positioning device

A technology for connecting structures and car doors, which is applied in the field of car body parts, can solve problems such as large lengths and affecting car handling performance, and achieve the effect of avoiding gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

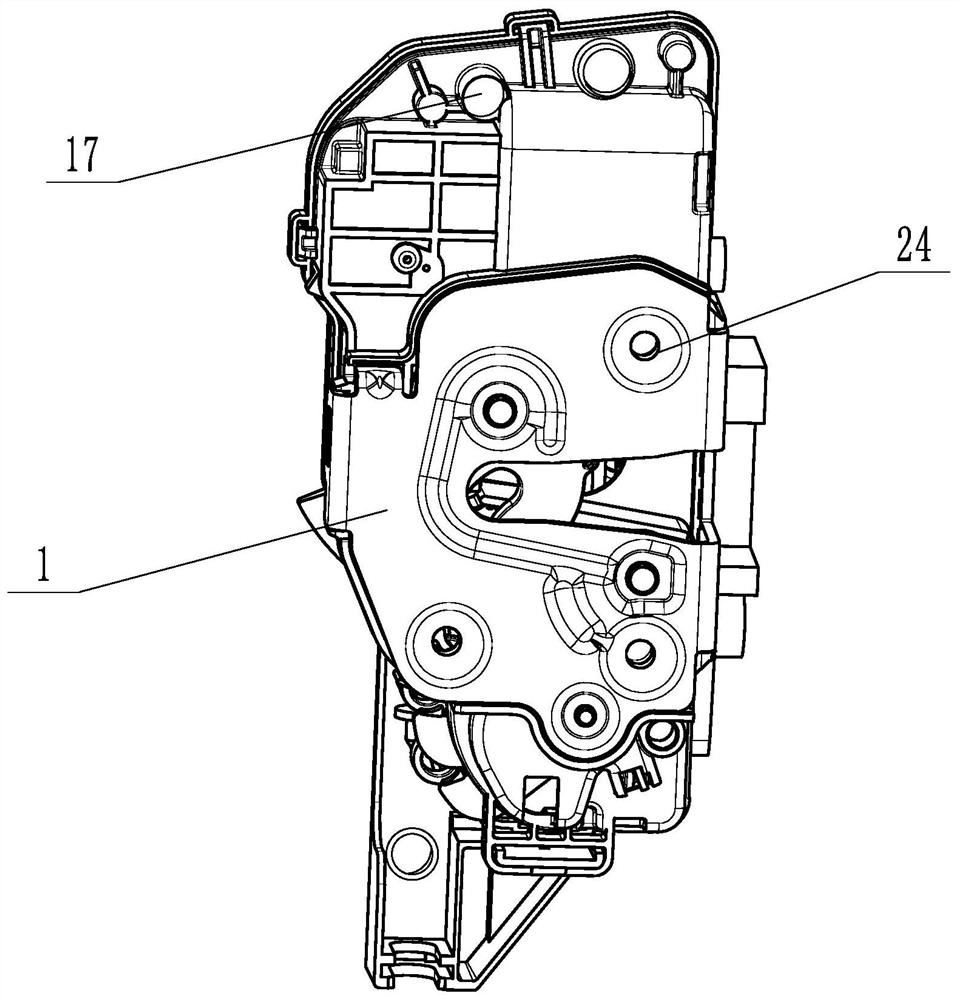

[0035] Number 24 is the threaded connection hole that the door lock device is fastened and connected with the mounting screw.

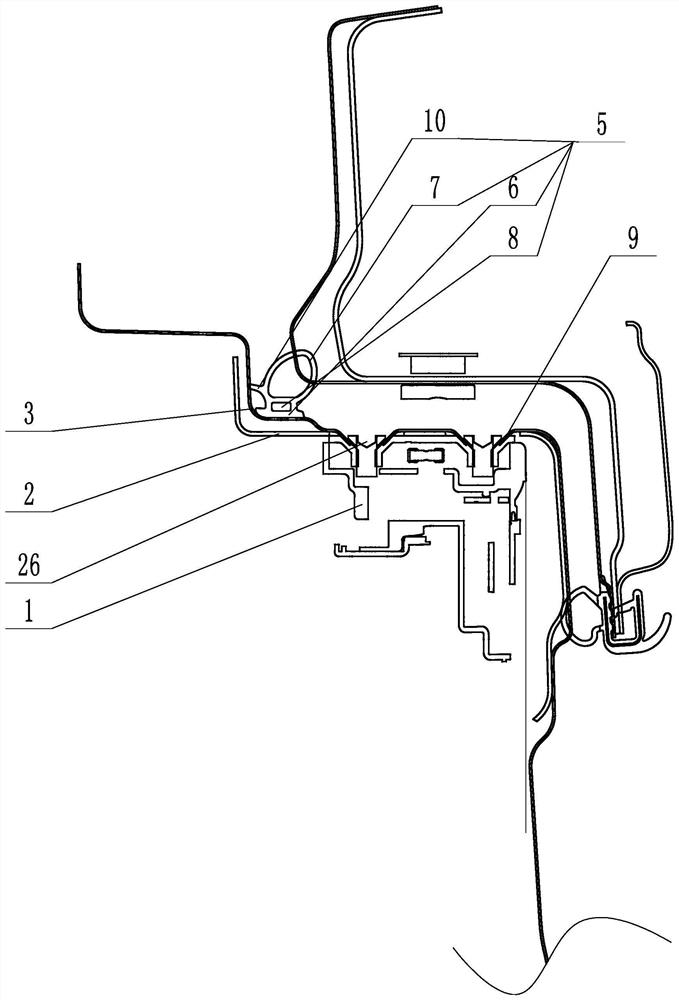

[0036] The door inner panel 3 and the door lock reinforcement plate 2 are processed into inwardly recessed tapered holes through the position of the mounting screws 4 through the stamping process, the door inner panel 3 and the door lock reinforcement plate 2 are welded and connected, and the door lock is threaded through the mounting screws 4 On the inner panel 3 of the car door. The surface of the nut of the mounting screw 4 is flush with the inner panel 3 of the car door, and the lower bottom surface of the nut protrudes downward to form a spherical crown shape. The lower bottom surface of the nut and the tapered hole have a larger bonding area. Design the tapered hole of the car door inner panel 3 to interfere with the door lock in advance. The pre-interference is about 0.4mm-0.8mm. When the door lock is installed to the designed position, the ...

Embodiment 2

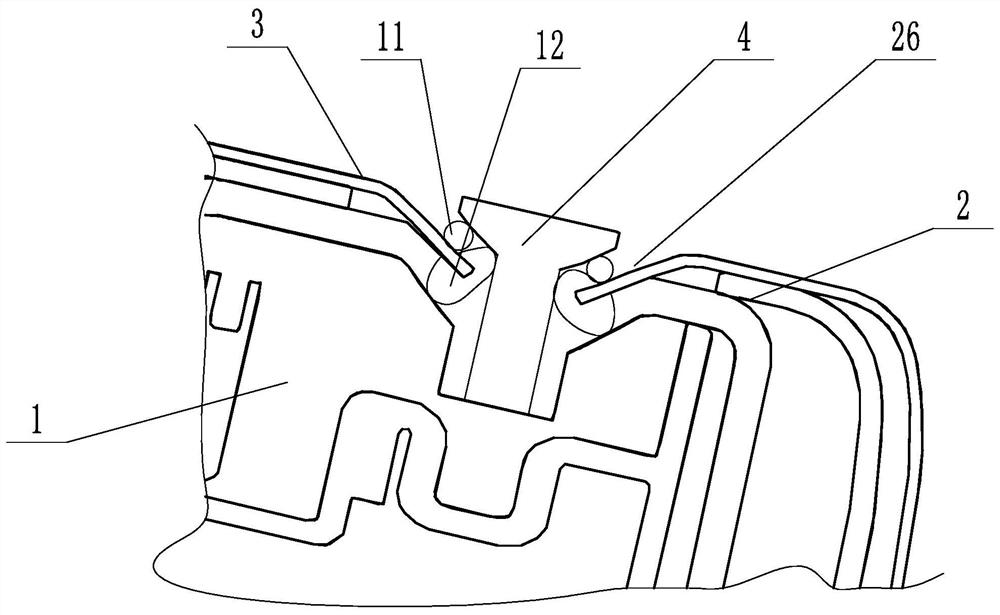

[0039] like Figure 4 As shown, there is no bottom plate 19 in the mounting portion 13, instead, the positioning hole 17 on the door lock device 1 is hexagonal. The threaded slider 25 includes an upper part 21 of the threaded slider and a lower part 22 of the threaded slider. The upper part 21 of the threaded slider is inserted into the positioning hole 17 of the door lock device. The hexagons and hexagonal prisms here are only for illustration, and in practical applications, any shape that can make the threaded slider 25 not rotate with the threaded rod 16 can be adopted.

[0040] The mechanical arm firstly attaches the door lock device 1 to the threaded rod 16, and then abuts each threaded rod 16 in the positioning groove 18. After the alignment is completed, the motor 15 works. Due to the existence of multiple connection points, the door lock device 1 does not occur. Instead, the rotation of the threaded rod 16 is converted into a forward and backward movement of the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com