Glue discharging nozzle for one-step beauty seam construction

A technology of glue nozzle and beautiful seam, applied in the field of beautiful seam, can solve the problems of high replacement frequency of glue nozzle, increase labor cost, increase construction cost, etc., and achieve the effect of less glue consumption, simple structure and improved utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

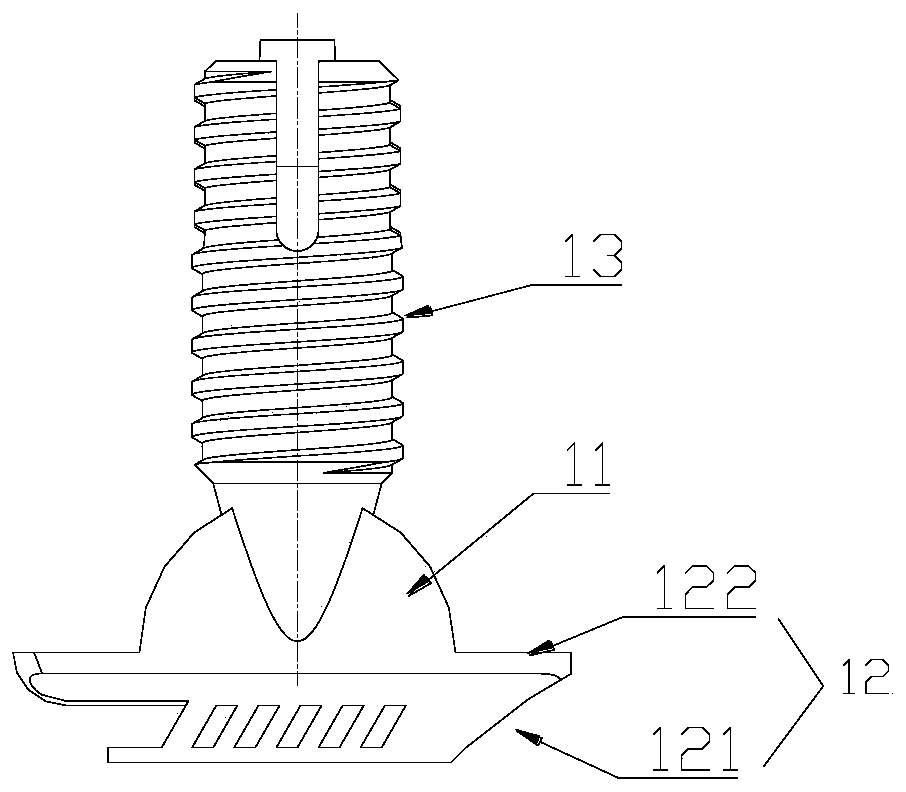

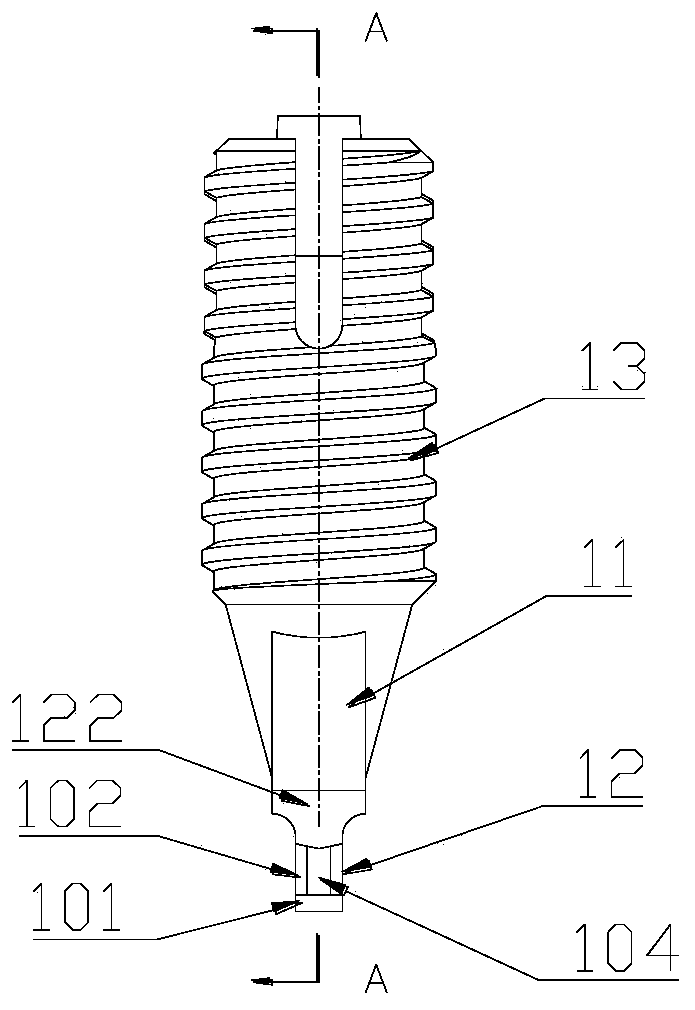

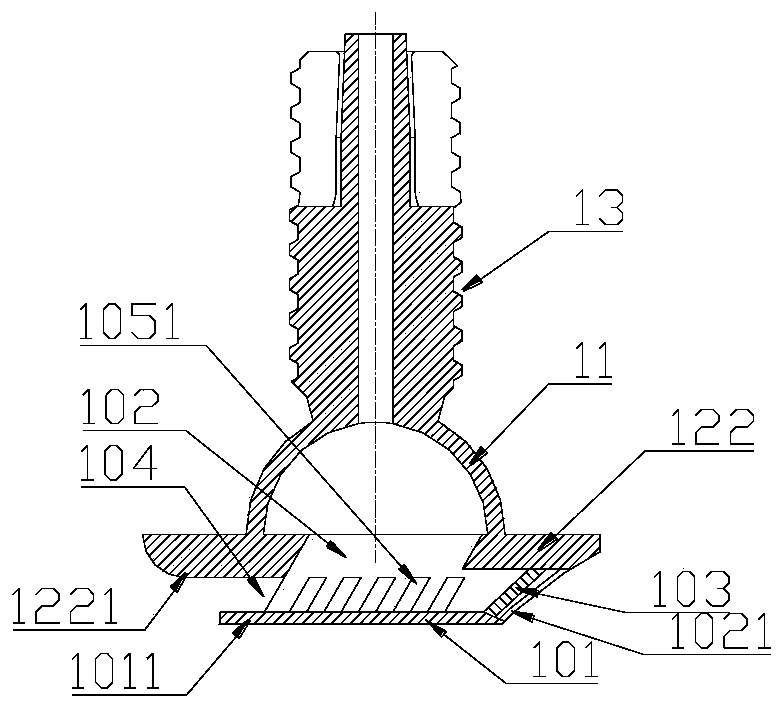

[0032] Such as figure 1 , figure 2 , image 3 As shown, a glue nozzle that completes the beautiful seam construction in one step includes a glue nozzle body 11, and the glue nozzle body 11 is a generally flat hard box body, which can be in the shape of a triangle, a square, a special shape, etc. This embodiment gives The glue outlet nozzle body 11 is a semicircle. Of course, since the glue nozzle body 11 does not need to be inserted into the tile seam, the glue nozzle body 11 can also be a non-flat body, such as a circle, a cube, a special shape, etc. The nozzle body 11 is provided with a shroud 12 under it, and a joint 13 connected with the rubber pipe is provided above it. Such as Figure 5 As shown, the joint 13 includes a screw joint 131 with an external thread and a plug joint 132 at the center of the screw joint 131; the plug joint 132 is coaxial with the screw joint 131 and an annular cavity 133 for accommodating the end of the rubber tube is left therebetween The...

Embodiment 2

[0038] Such as figure 1 , 5 As shown, the difference between this embodiment and Embodiment 1 is that the angle between the end surface of the side plate 102 and the bottom plate 101 is greater than 90°, and the angle between the end surface and the bottom plate towards the direction of travel is less than 90°, generally about 45° is appropriate, and the structure The guide end 107 is convenient for inserting the gluing part into the seam of tiles.

Embodiment 3

[0040] Such as image 3 , Figure 4 , Figure 5 As shown, in order to prevent the glue from falling into the bottom of the tile seam, this embodiment is based on Embodiment 1, and the end of the bottom plate 101 facing away from the traveling direction is designed to be longer than the side plate 102 to form a glue baffle 1011 . After the beautifying agent comes out from the first glue outlet 104, it is buffered by the rubber baffle 1011, so that it will not quickly fall into the bottom of the seam under the pressure of glue application, thereby saving glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com