Relief wine box and manufacturing process thereof

A manufacturing process and embossing technology, which is applied in the field of embossed wine boxes and its manufacturing process, can solve the problems of high defective rate, easy degumming, poor three-dimensional effect, etc., and achieve the effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

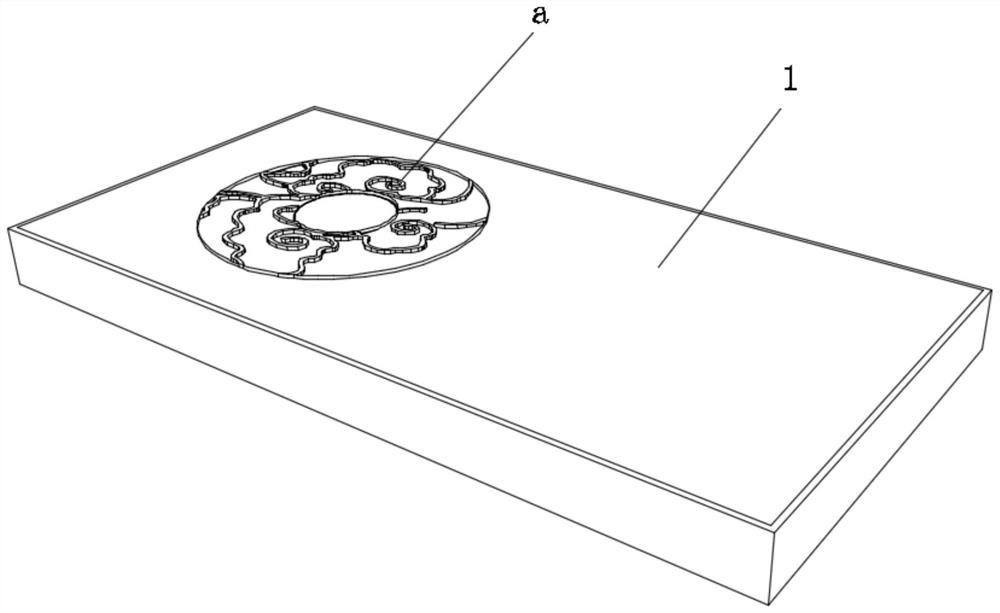

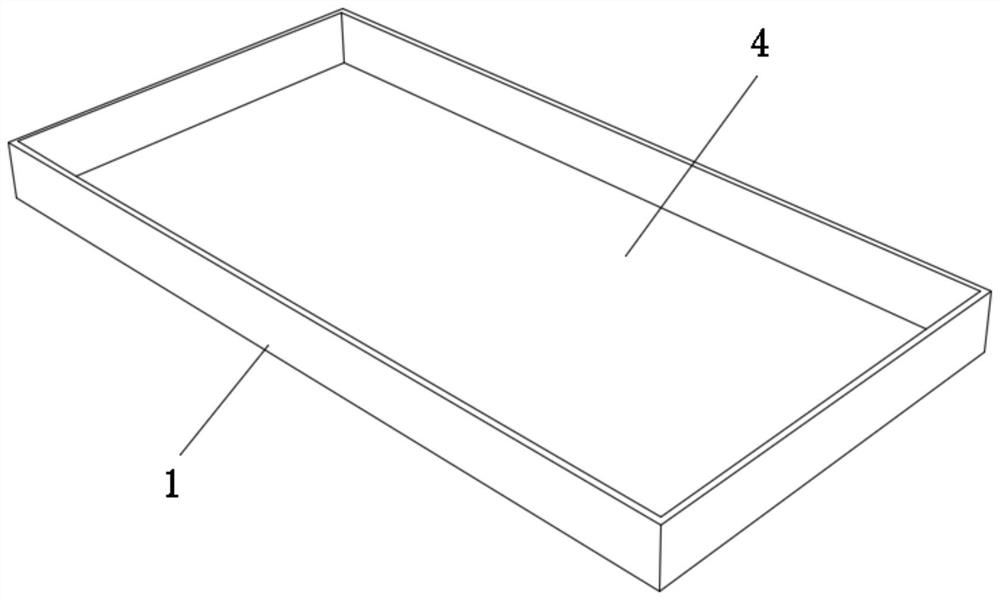

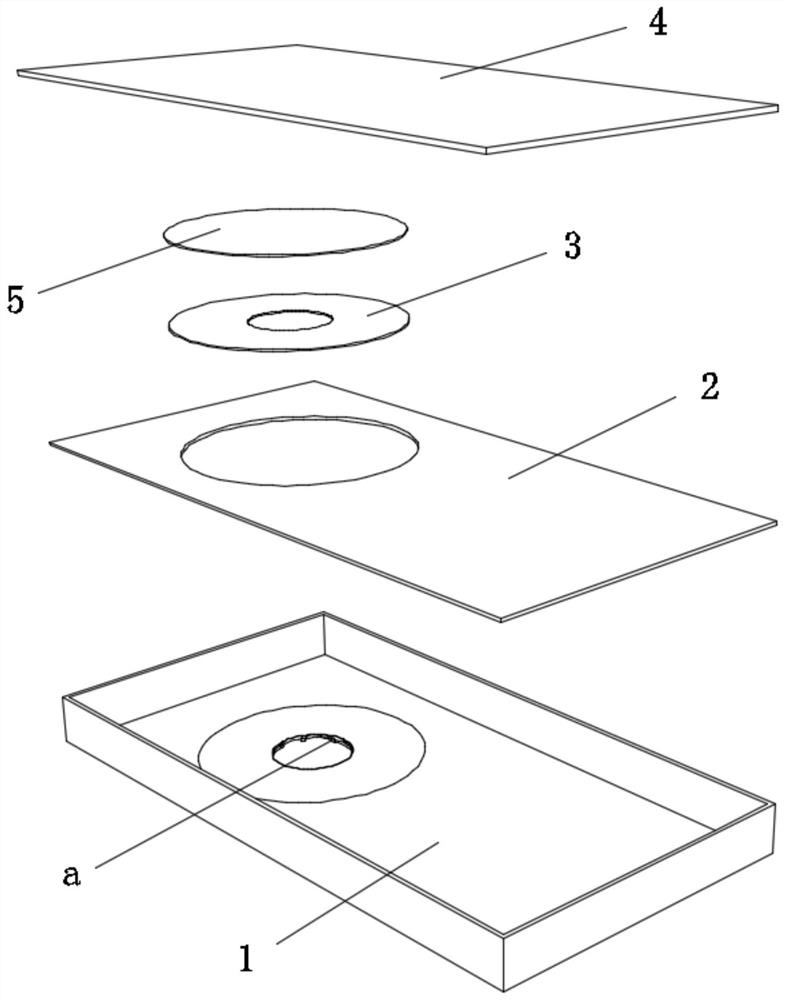

[0035] Embodiment 1: a kind of embossed wine box, such as Figure 1-Figure 3 As shown, it includes: an outer packaging box 1 with an embossed finish a, a first grey cardboard layer 2 , a second grey cardboard layer 5 , a soft layer 3 and an inner lining layer 4 . Simple structure and low cost.

[0036] Wherein, the first gray cardboard layer 2 is fixedly adhered to the inner side of the outer packaging box 1, and is hollowed out at a position corresponding to the embossed surface a. The soft layer 3 is fixedly adhered to the inner side of the outer packaging box 1 , filled in the hollowed out place of the first grey cardboard layer 2 , and used to push out the position a of the embossed surface of the outer packaging box 1 . The inner lining layer 4 is fixedly adhered to the other side of the first gray cardboard layer 2 and covers the soft layer 3 . The second gray cardboard layer 5 is fixedly adhered to the other side of the soft layer 3 , and the second gray cardboard lay...

Embodiment 2

[0050] Embodiment 2: a kind of embossed wine box, such as figure 1 , figure 2 and Figure 4 As shown, it includes: an outer packaging box 1 with an embossed finish a, a first grey cardboard layer 2 , a soft layer 3 and an inner lining layer 4 . Simple structure and low cost.

[0051] Wherein, the first gray cardboard layer 2 is fixedly adhered to the inner side of the outer packaging box 1, and is hollowed out at a position corresponding to the embossed surface a. The soft layer 3 is fixedly adhered to the inner side of the outer packaging box 1 , filled in the hollowed out place of the first grey cardboard layer 2 , and used to push out the position a of the embossed surface of the outer packaging box 1 . The inner lining layer 4 is fixedly adhered to the other side of the first gray cardboard layer 2 and covers the soft layer 3 .

[0052] After the soft layer 3 is fixed and pasted, the soft layer 3 is flush with the first gray cardboard layer 2 .

[0053] In this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com