Corridor roof connection structure

A technology for connecting structures and steel beams, which is applied in building construction, construction, etc., and can solve problems such as large size and weight, poor strength and reliability, and overlapping welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031]This embodiment provides a middle corridor roof connection structure.

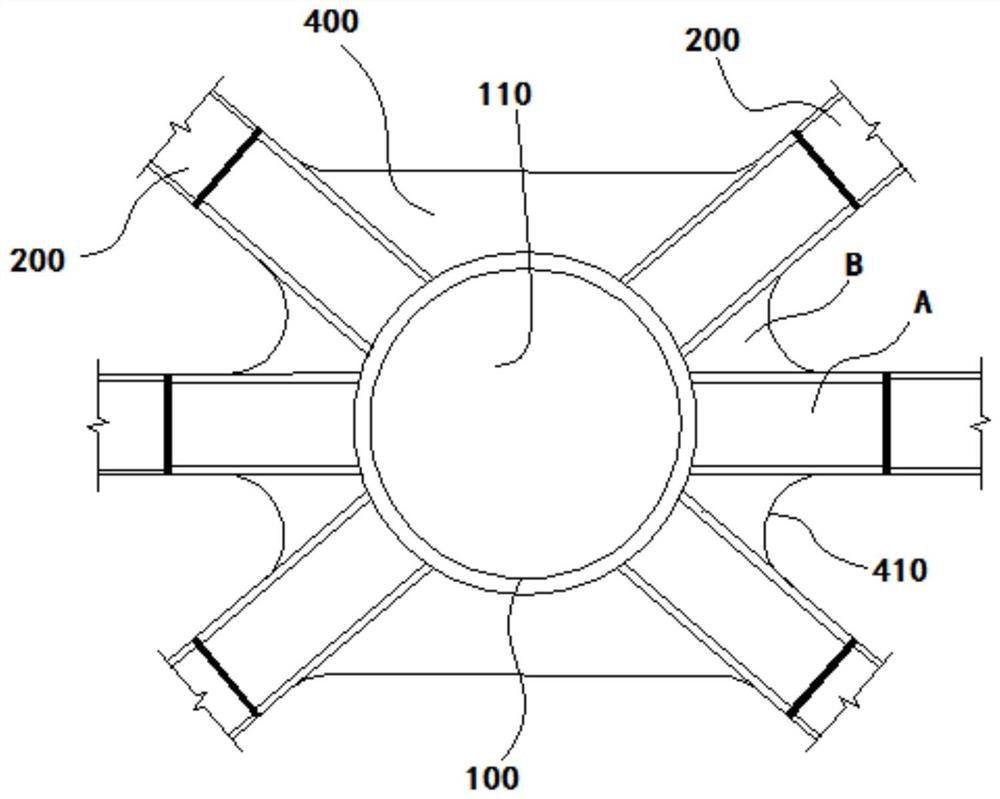

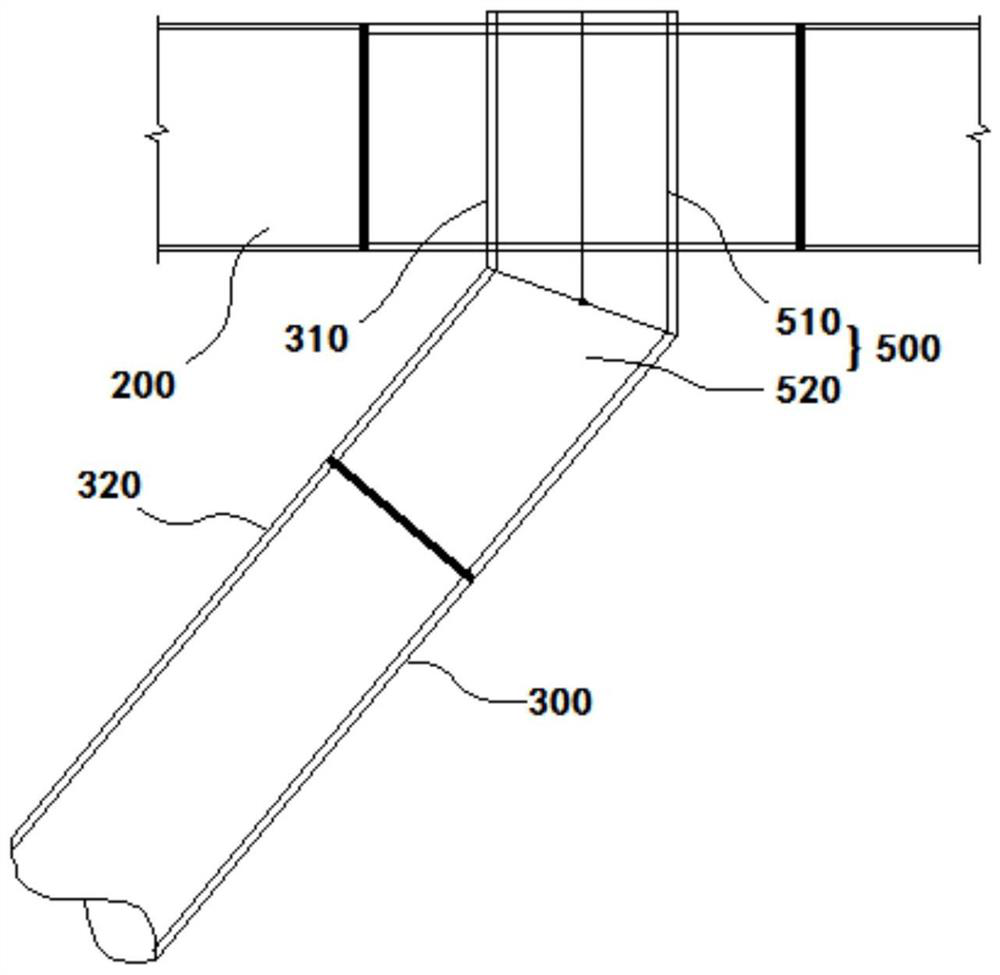

[0032]Please refer toFigure 1-2The middle corridor roof connection structure includes a middle round pipe 100, a roof steel beam 200, and a roof bifurcation column 300.

[0033]Wherein, the intermediate round tube 100 has a hollow installation channel 110, which is mainly used as an intermediate medium for connecting the roof steel beam 200 and the roof bifurcation column 300.

[0034]The roof steel beam 200 is welded to the peripheral wall of the middle round tube 100, and the roof bifurcation column 300 is welded to the installation channel 110.

[0035]In this way, due to the arrangement of the middle round tube 100, the roof steel beam 200 and the roof bifurcation column 300 can be welded with the middle round tube 100 as a medium, and the roof steel beam 200 can be welded to the peripheral wall of the middle round tube 100, and The roof bifurcated column 300 can be welded in the installation channel 110 of the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com