A system and method for acquiring and managing three-dimensional data on the surface of a civil aviation aircraft fuselage

A technology of three-dimensional data and management system, applied in image data processing, TV system components, supporting machines, etc., can solve problems such as accidental scratches on the fuselage, high labor intensity, and increased labor intensity of inspectors, etc., to achieve a comprehensive image The effect of covering collection, reducing labor intensity, and improving inspection and maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

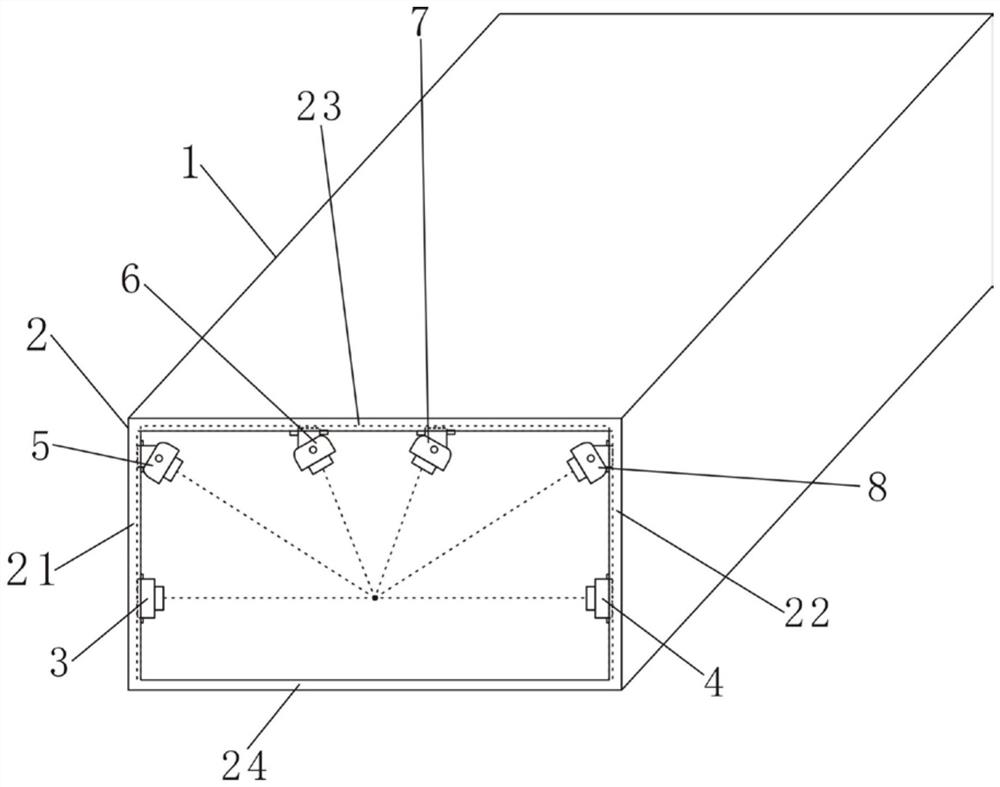

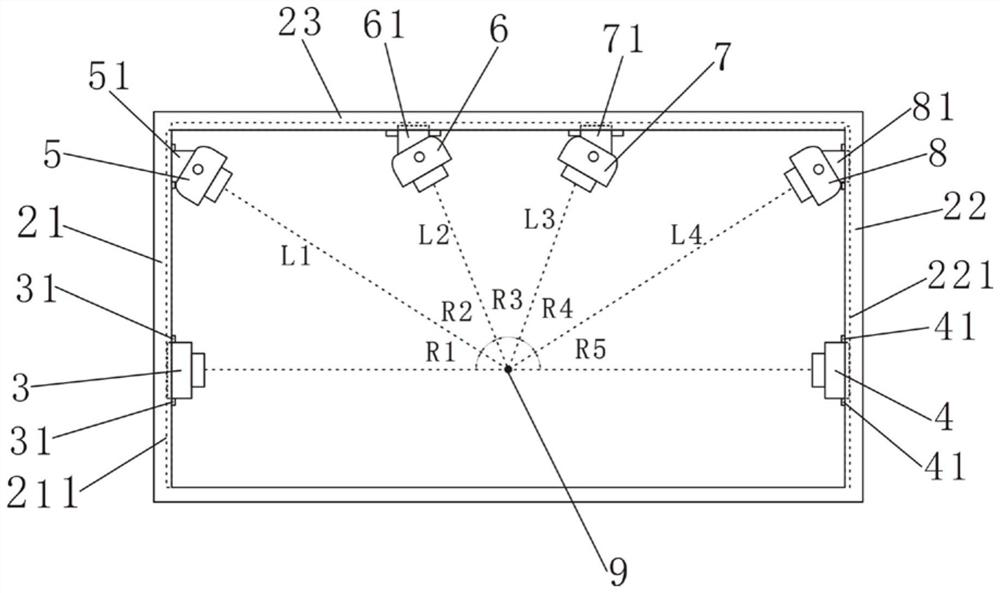

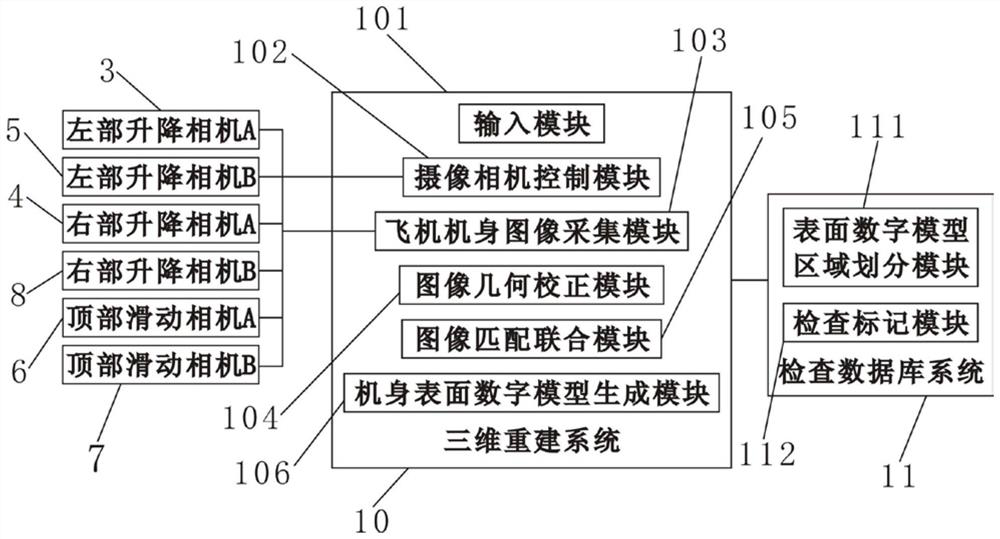

[0031] Such as Figure 1 ~ Figure 3 As shown, a three-dimensional data acquisition and management system for the fuselage surface of a civil aviation airliner includes a hangar 1, the hangar door of the hangar 1 is provided with a hangar acquisition door frame 2, and the hangar acquisition door frame 2 includes a left frame 21, a right door frame 22 and top frame 23, vertically have lifting chute A211 on the left frame 21, as figure 1 , figure 2 As shown, in the lifting chute A211 of the present embodiment, the left lifting camera A3 and the left lifting camera B5 are sequentially lifted and slidably installed from bottom to top, the left lifting camera A3 is provided with a lifting slider A, and the left lifting camera A3 The lifting slider A is slidably fitted in the lifting chute A211, and the upper and lower sides of the left lifting camera A3 are respectively fixed with positioning locks A31, and the shooting direction of the photographing lens A of the left lifting cam...

Embodiment 2

[0040] Such as Figure 1 ~ Figure 3 As shown, a three-dimensional data acquisition and management system for the fuselage surface of a civil aviation airliner includes a hangar 1, the hangar door of the hangar 1 is provided with a hangar acquisition door frame 2, and the hangar acquisition door frame 2 includes a left frame 21, a right door frame 22 and top frame 23, vertically have lifting chute A211 on the left frame 21, as figure 1 , figure 2 As shown, in the lifting chute A211 of the present embodiment, the left lifting camera A3 and the left lifting camera B5 are sequentially lifted and slidably installed from bottom to top, the left lifting camera A3 is provided with a lifting slider A, and the left lifting camera A3 The lifting slider A is slidably fitted in the lifting chute A211, and the upper and lower sides of the left lifting camera A3 are respectively fixed with positioning locks A31, and the shooting direction of the photographing lens A of the left lifting cam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com