Baking torch device of ship steel structure

A steel structure and torch technology, applied in welding equipment, metal processing equipment, gas flame welding equipment, etc., can solve problems such as prone to accidents, inconvenient inspection by staff, and delays in construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

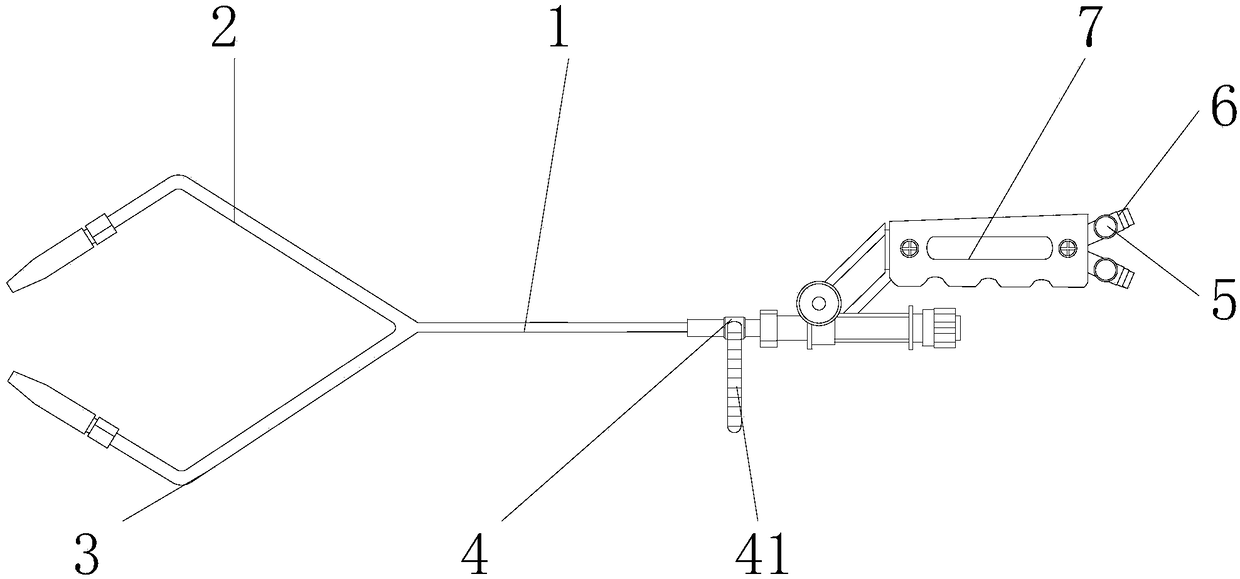

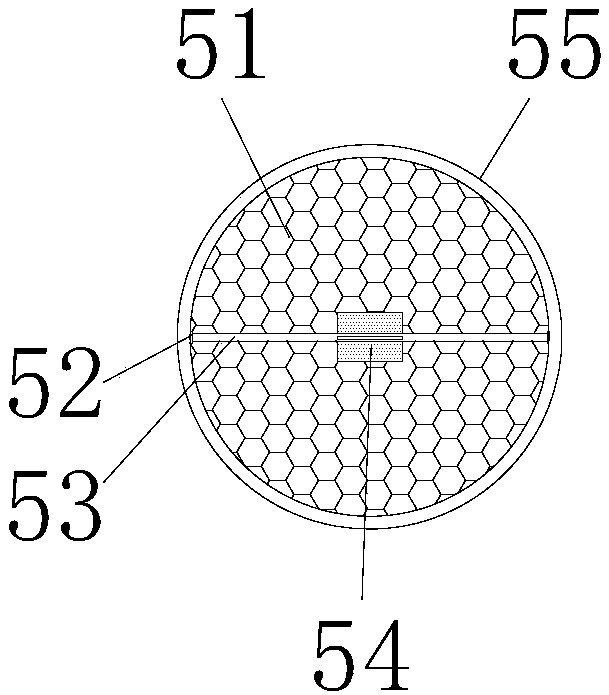

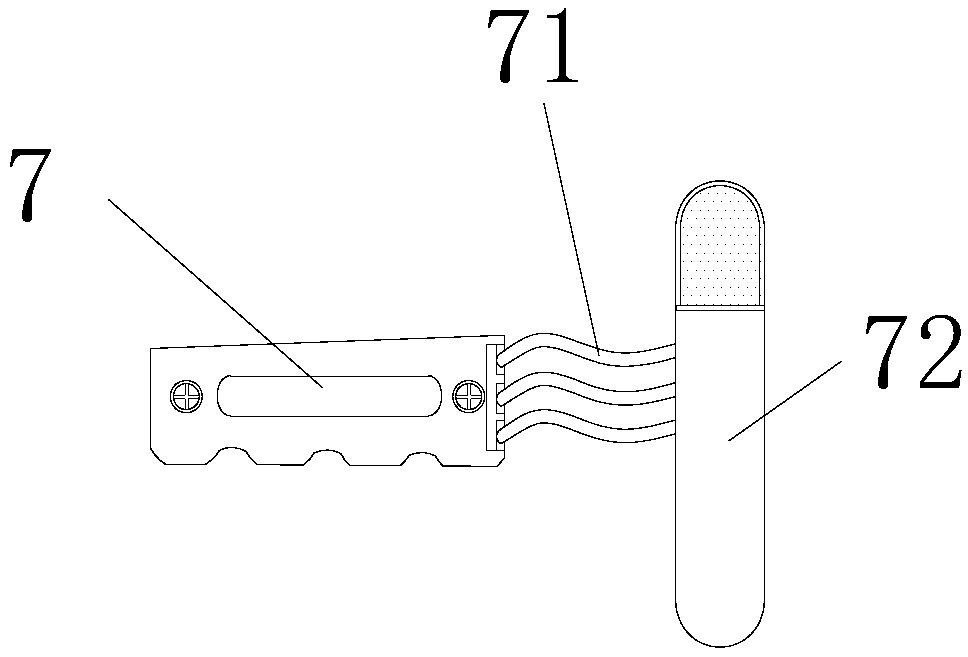

[0029] A kind of torch equipment with ship steel structure, comprising a torch body 1, a first welding tip 2 fixed on one end of the torch body 1, a second welding tip 3 fixed on one end of the torch body 1, and close to the first welding tip 2, the torch body 1, the first welding tip 2 and the second welding tip 3 are integrally formed, the spring automatic return ball valve 4 is welded and fixed inside the torch body 1, and the ball valve handle 41 is rotatably connected to the spring automatic return ball valve 4, the handle 7 is welded and fixed on the side of the torch body 1 away from the first welding tip 2, the two connecting pipes 6 are welded and fixed on the end of the handle 7 away from the first welding tip 2, and the inspection mechanism 5 is welded and fixed on the Connecting to the inside of the pipe 6 , the connecting rope 71 is glued and fixed on the front surface of the handle 7 , and the Velcro strap 72 is glued and fixed on the end of the connecting rope 71...

Embodiment 2

[0047] The difference from Example 1 is that the handle 7 is coated with an anti-skid layer, and the preparation method of the anti-skid layer is:

[0048]Take the following raw materials for each component by weight: 22.3 parts of epoxy resin, 13.6 parts of polyalkylaryl silicone resin, 5.7 parts of silicon dioxide powder, 7 parts of titanium dioxide, 3 parts of aluminum powder, isophorone two 4.2 parts of amine, 1.6 parts of polyethylene polyamine, 2.3 parts of alkyl glucoside, 22.1 parts of ethylene glycol ether.

[0049] S1. Grinding: Mix silicon dioxide powder, titanium dioxide, aluminum powder, isophorone diamine, polyethylene polyamine, and alkyl glucoside and stir evenly. Grind at a high speed in a ball mill until a mesh size of 42 is obtained. between the powder;

[0050] S2. Preparation of color paste: adding epoxy resin, polyalkylaryl silicone resin, and ethylene glycol ether to the powder obtained in S1, and performing high-speed grinding to a fineness of 32 μm to...

Embodiment 3

[0056] The difference from Example 2 is that the specific gravity of the formula has been modified, and the modified formula is:

[0057] Take the following raw materials of each component by weight for later use: 25.9 parts of epoxy resin, 15.4 parts of polyalkylaryl silicone resin, 5.9 parts of silicon dioxide powder, 9 parts of titanium dioxide, 4 parts of aluminum powder, isophorone two 4.8 parts of amine, 1.8 parts of polyethylene polyamine, 2.5 parts of alkyl glucoside, 23.5 parts of ethylene glycol ether.

[0058] S1. Grinding: Mix silicon dioxide powder, titanium dioxide, aluminum powder, isophorone diamine, polyethylene polyamine, and alkyl glucoside and stir evenly. Grind at a high speed in a ball mill until a mesh size of 42 is obtained. between the powder;

[0059] S2. Preparation of color paste: adding epoxy resin, polyalkylaryl silicone resin, and ethylene glycol ether to the powder obtained in S1, and performing high-speed grinding to a fineness of 32 μm to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com