A phase-stabilized method for unbalanced motion control of magnetic suspension bearing rotors

A magnetic levitation bearing and rotor unbalanced technology, applied in the direction of anti-centrifugal force rotating parts, bearings, shafts and bearings, can solve problems such as system failures and system dynamic performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

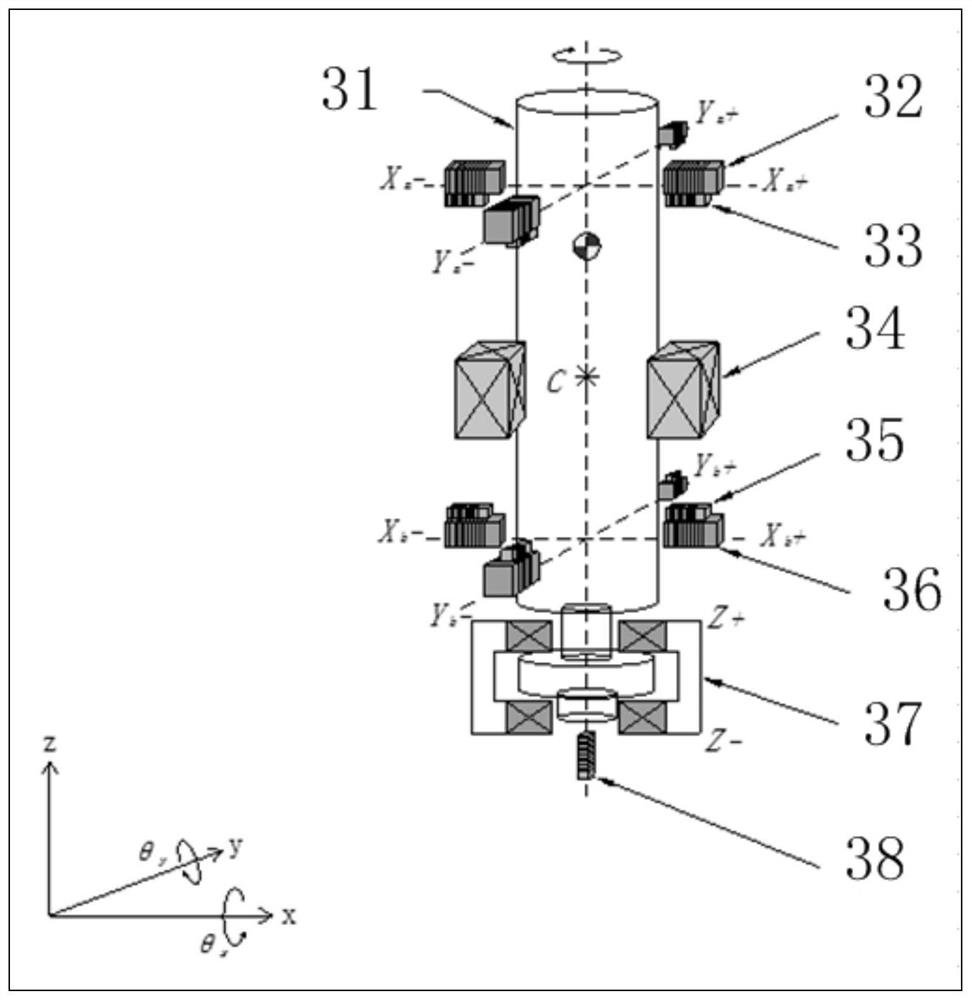

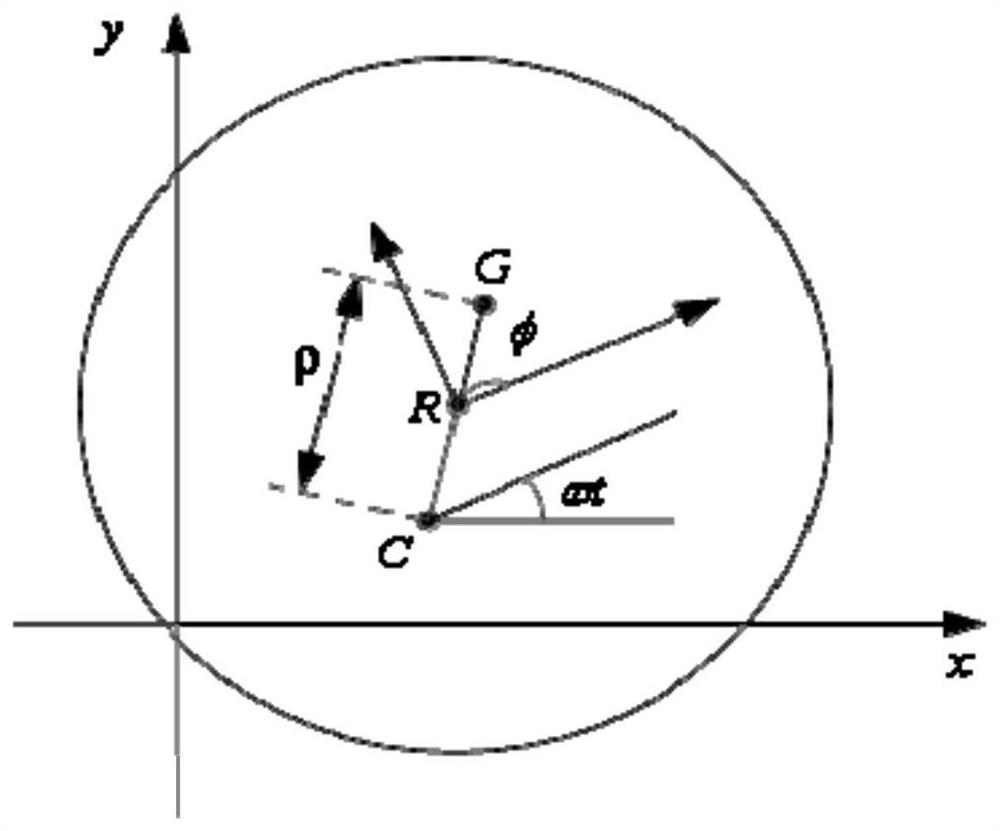

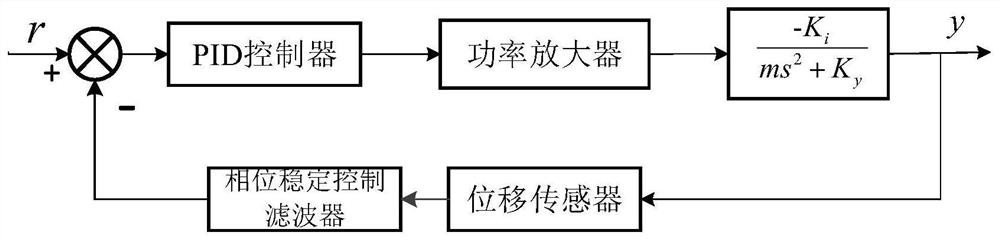

[0031] Since the displacement signal detected by the sensor is mixed with a disturbing signal, the electromagnetic force generated by the control current cannot make the rotor move around the shaft. produce unbalanced vibrations. This unbalanced vibration has a great influence on the dynamic performance index of the system, and the range of vibration exceeds the maximum range, which will cause system failure. Aiming at this disturbance signal, the present invention designs a phase-stable control method to reduce its influence on the system controller. combine Figure 1 to Figure 5 , the steps of the present invention are as follows:

[0032] Step S1: Establish the magnetic suspension bearing rotor system coordinate system, establish the x and y axes in the radial direction of the magnetic suspension bearing, and the z axis in the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com