Inclined ejector multi-directional core pulling mechanism of middle frame injection mold

A technology of injection mold and core-pulling mechanism, which is applied in the field of inclined top multi-directional core-pulling mechanism, can solve the problems of increasing secondary ejection, increasing mold manufacturing cost, increasing the complexity of mold structure, etc., and achieves the effect of reducing unnecessary troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

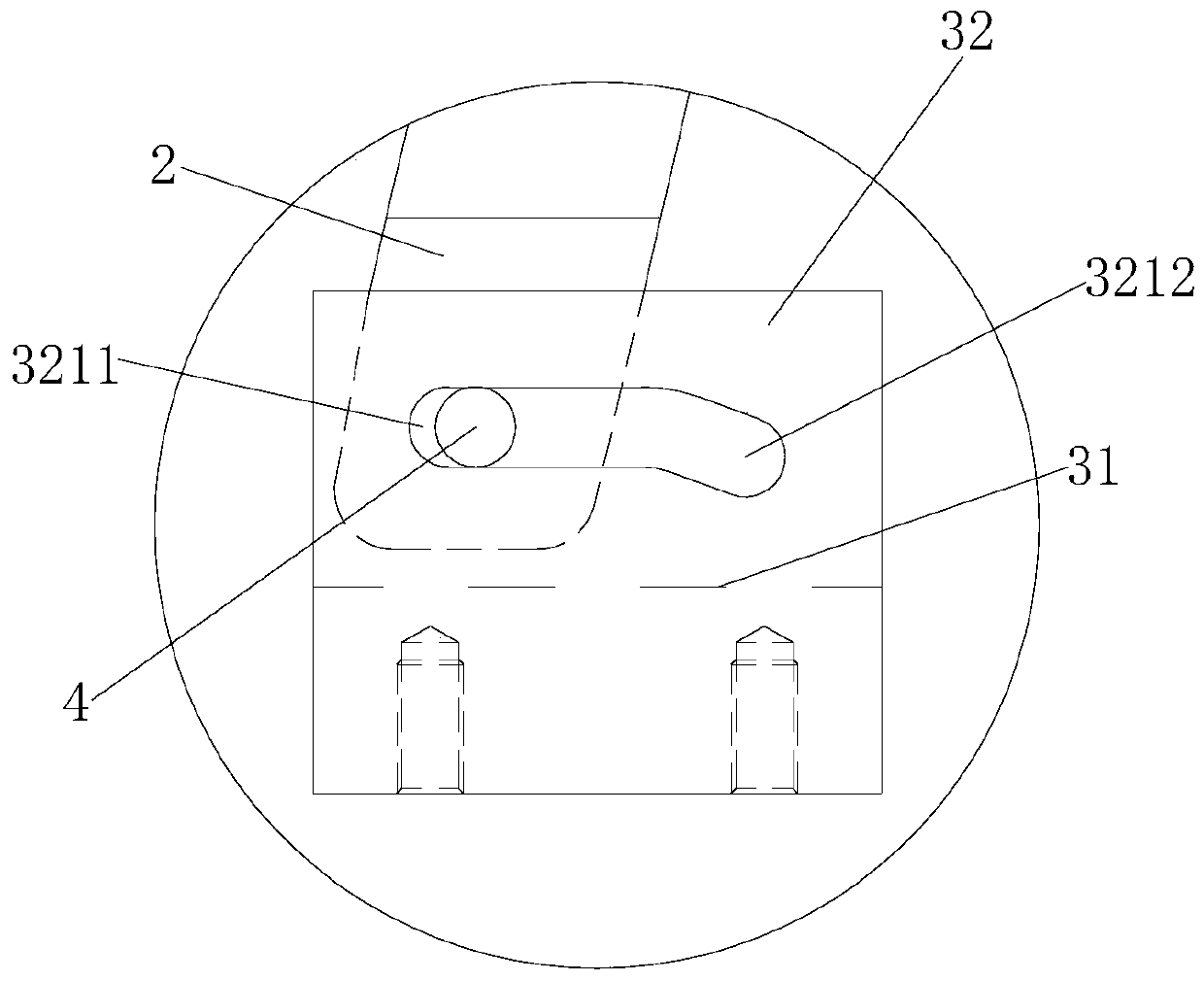

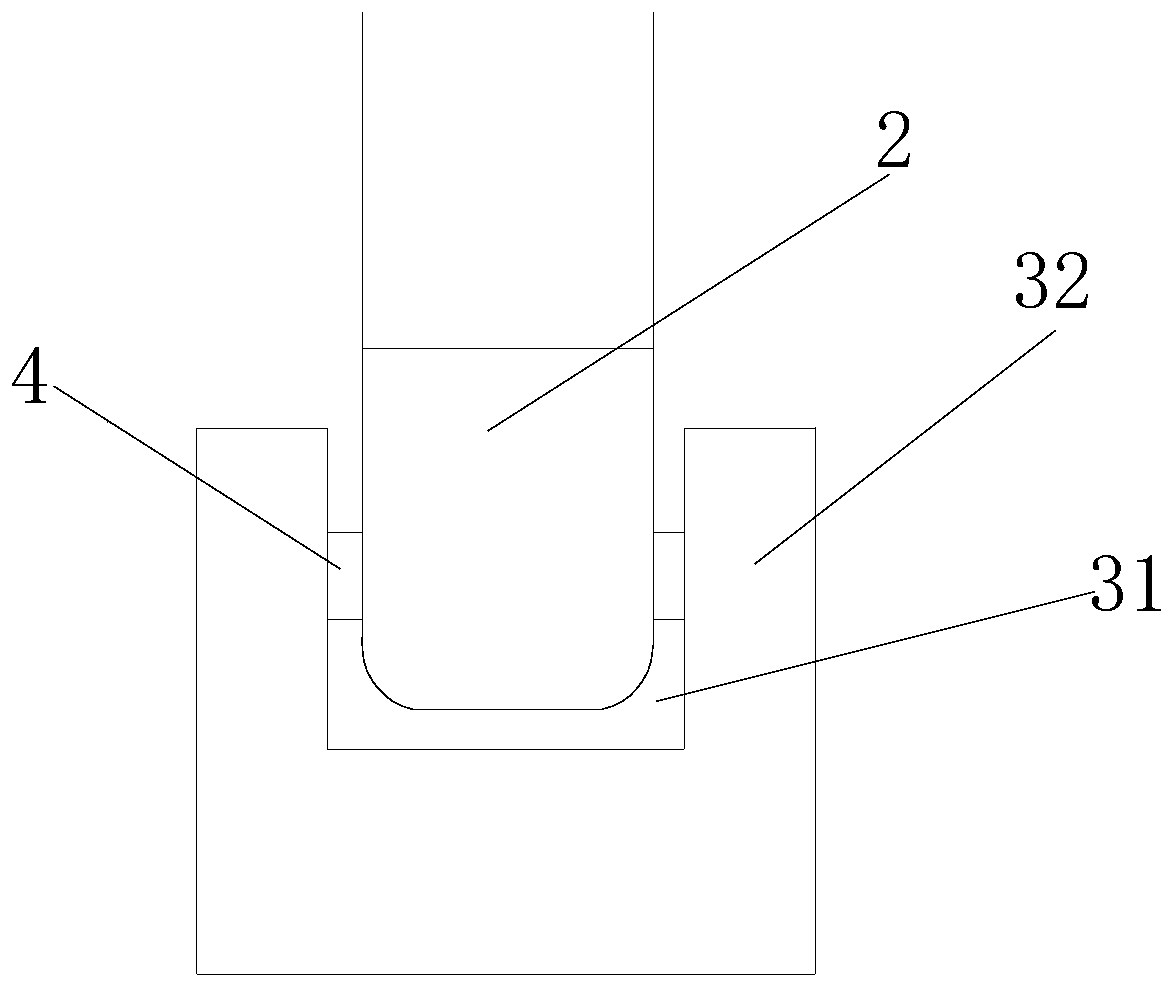

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Such as Figure 1-3 As shown, the inclined top multi-directional core-pulling mechanism of the middle frame injection mold includes an inclined ejector head 1, an inclined ejector rod 2 supporting the inclined ejector head 1, and a guide slider 3 for installing the inclined ejector rod 2. The inclined ejector The rod 2 is set obliquely. Described guide slider 3 is shaped on inclined top groove 31, as image 3 As shown, the tail of the inclined ejector rod 2 is located in the inclined ejector groove 31, and the guide slider 3 is fixedly installed on the ejector pin plate. The groove walls 32 on both sides of the inclined roof groove 31 are shaped on strip holes 321, such as figure 2 As shown, the first half section of the strip hole 321 is a horizontal section 3211 arranged horizontally, and the second half section is an inclined section 3212 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com