Integrated intelligent equipment and processing technology for post-processing of hemp degumming

An intelligent device and hemp degumming technology are applied in the processing of textile material equipment configuration, textile material processing, and textile material container processing, which can solve the problem of increased workload of processing equipment maintenance and maintenance, labor-intensive or transshipment equipment, and huge Take up space and other issues, to achieve the effect of reducing unnecessary trouble, balanced quality, energy saving and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

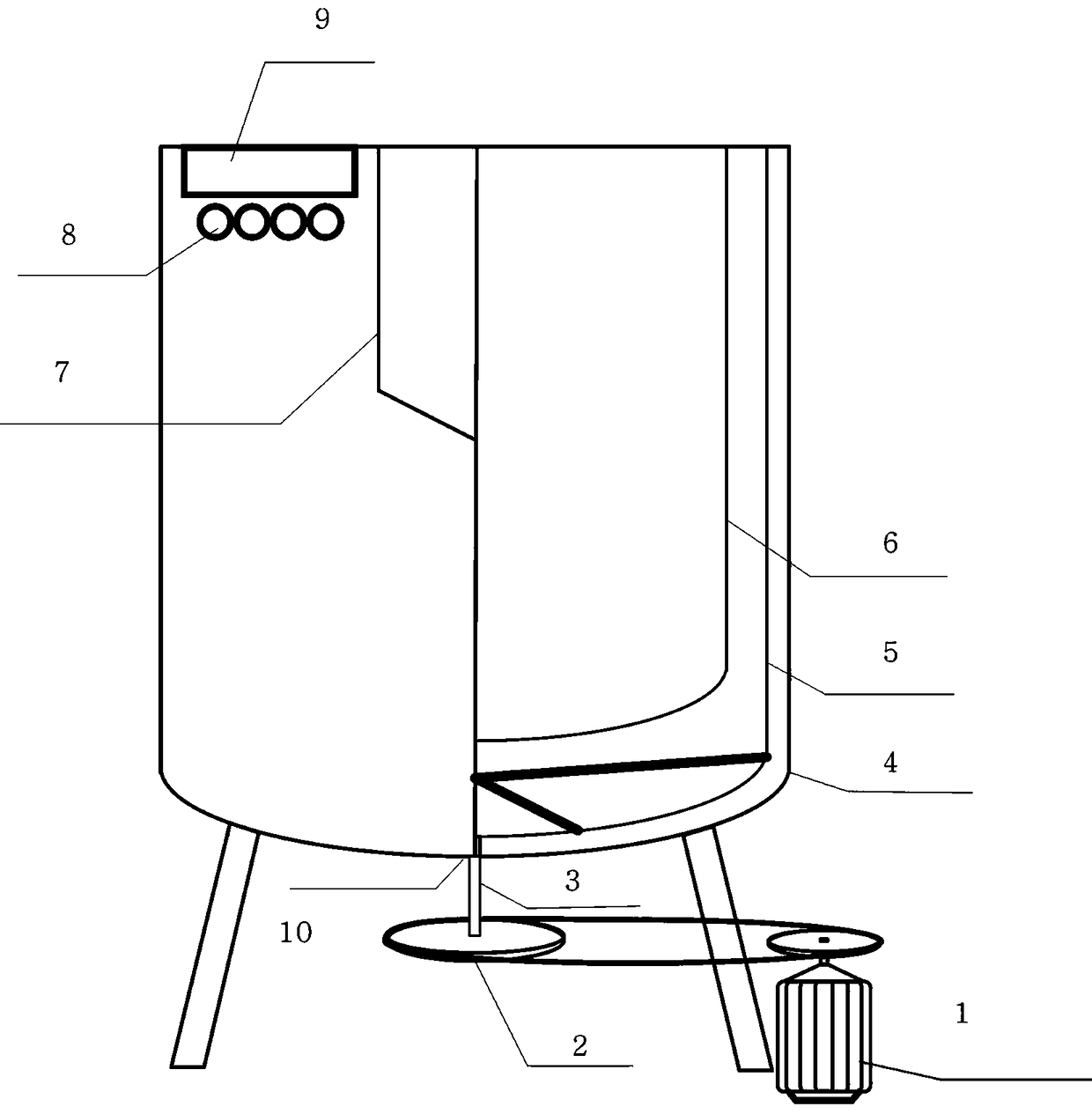

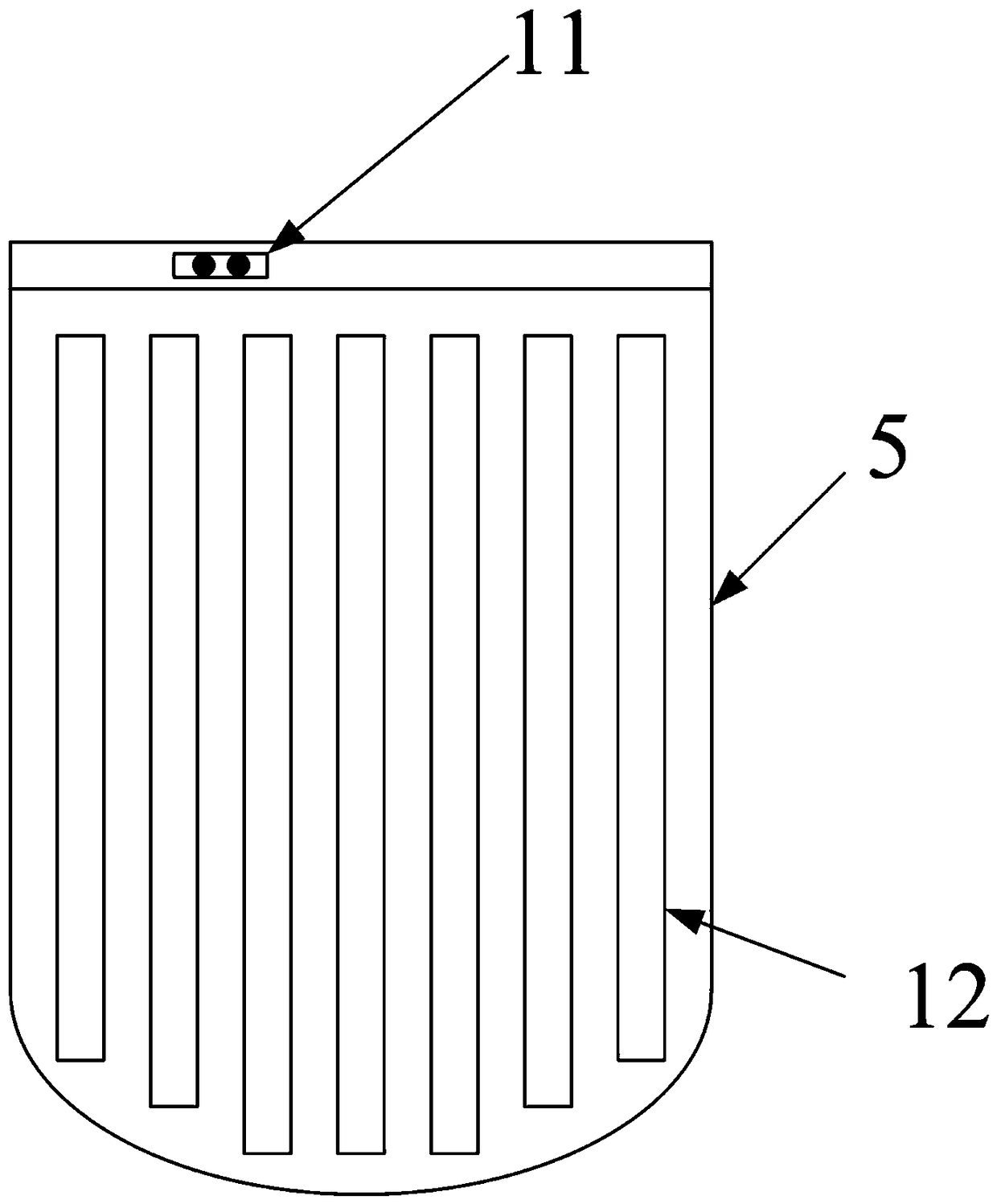

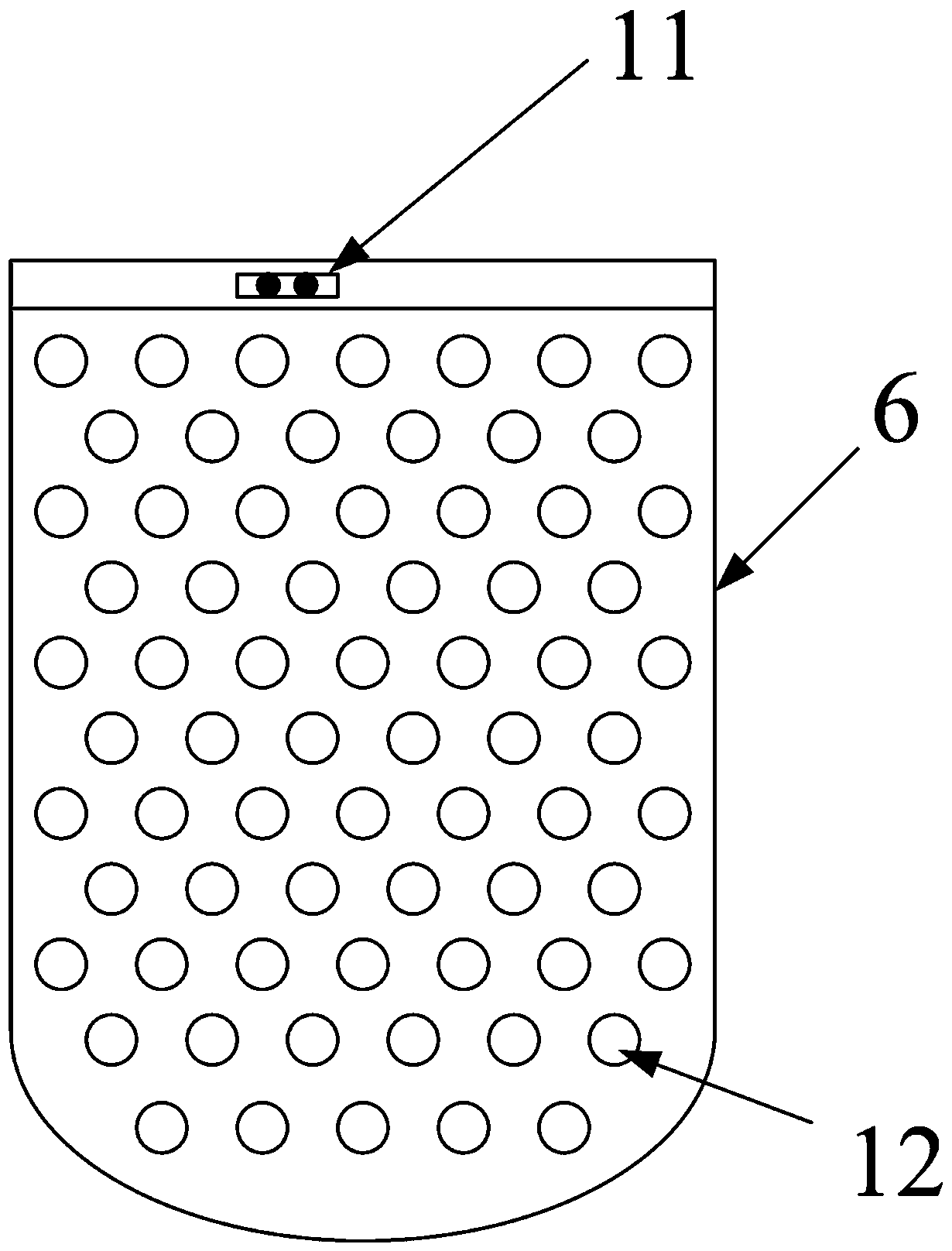

[0042] Such as Figure 1-4 As shown, an integrated intelligent device for hemp degumming post-processing, including motor (1), pulley (2), connecting shaft (3), tank body (4), cradle (5), moving barrel (6 ), the movable door (7), the liquid inlet (8) and the liquid outlet (10), the motor (1) is connected with the pulley (2) through the transmission belt, and drives the rotation of the pulley (2), and the connecting shaft ( 3) One end is connected to the pulley (2), and the other end of the connecting shaft (3) passes through the bottom of the tank (4) to connect with the cradle (5). The top of the tank (4) is open, and the cradle ( 5) The top is open, the cradle (5) is set inside the tank (4), the cradle (5) rotates around the connecting shaft (3) as the central axis, and the moving barrel (6) is a barrel-shaped structure with an open top , the moving barrel (6) is installed in the cradle (5), the movable door (7) is a movable door structure of the body wall of the tank body ...

Embodiment 2

[0044] Such as Figure 1-7 As shown, an integrated intelligent device for hemp degumming post-processing, including motor (1), pulley (2), connecting shaft (3), tank body (4), cradle (5), moving barrel (6 ), the movable door (7), the liquid inlet (8) and the liquid outlet (10), the motor (1) is connected with the pulley (2) through the transmission belt, and drives the rotation of the pulley (2), and the connecting shaft ( 3) One end is connected to the pulley (2), and the other end of the connecting shaft (3) passes through the bottom of the tank (4) to connect with the cradle (5). The top of the tank (4) is open, and the cradle ( 5) The top is open, the cradle (5) is set inside the tank (4), the cradle (5) rotates around the connecting shaft (3) as the central axis, and the moving barrel (6) is a barrel-shaped structure with an open top , the moving barrel (6) is installed in the cradle (5), the movable door (7) is a movable door structure of the body wall of the tank body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com