Embedded part for cable bridge laying and construction method thereof

A technology of embedded parts and cables, which is applied to bridge parts, bridge construction, bridges, etc., can solve the problems of potential safety hazards, waste of templates, etc., and achieve the effects of firm fixing, convenient use, and elimination of potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

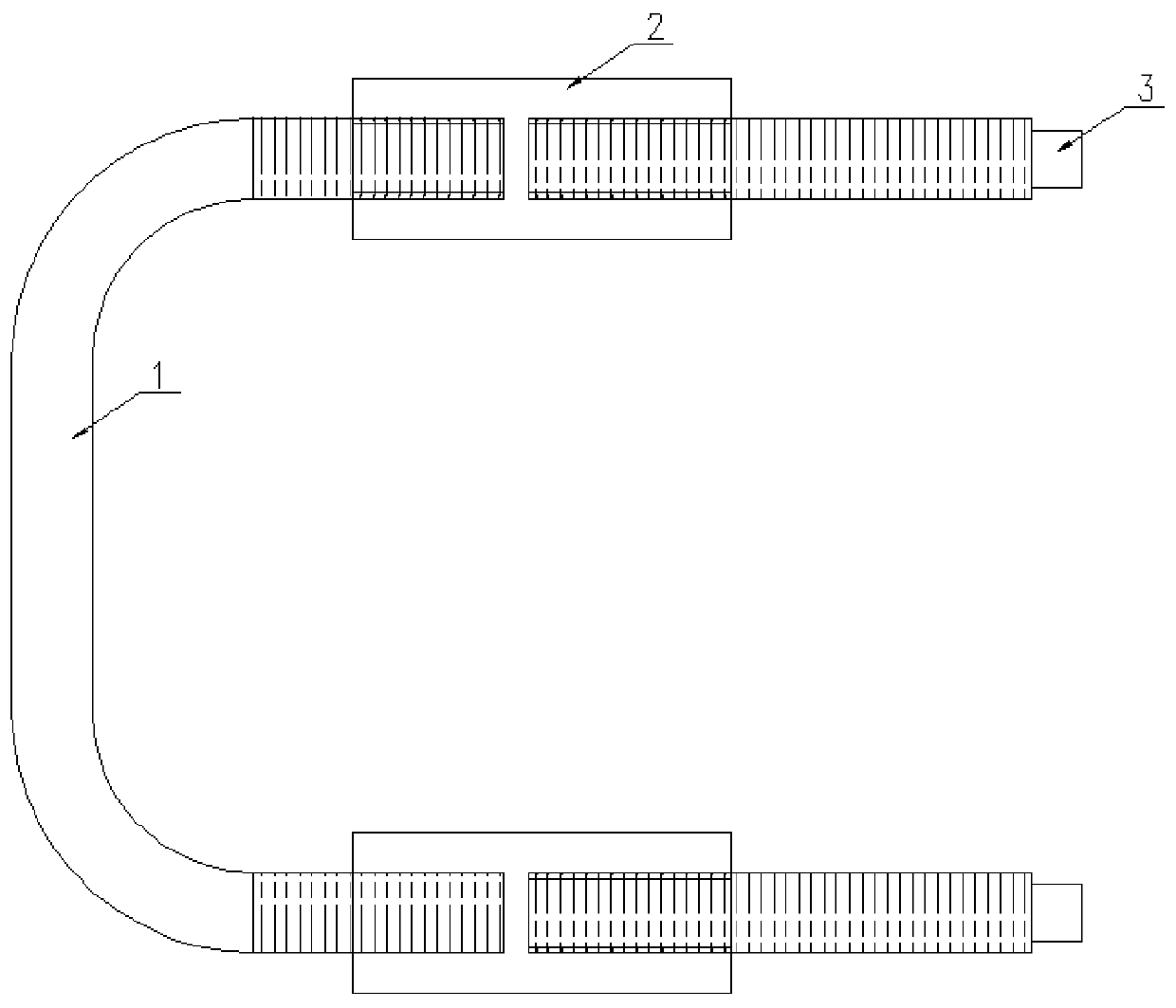

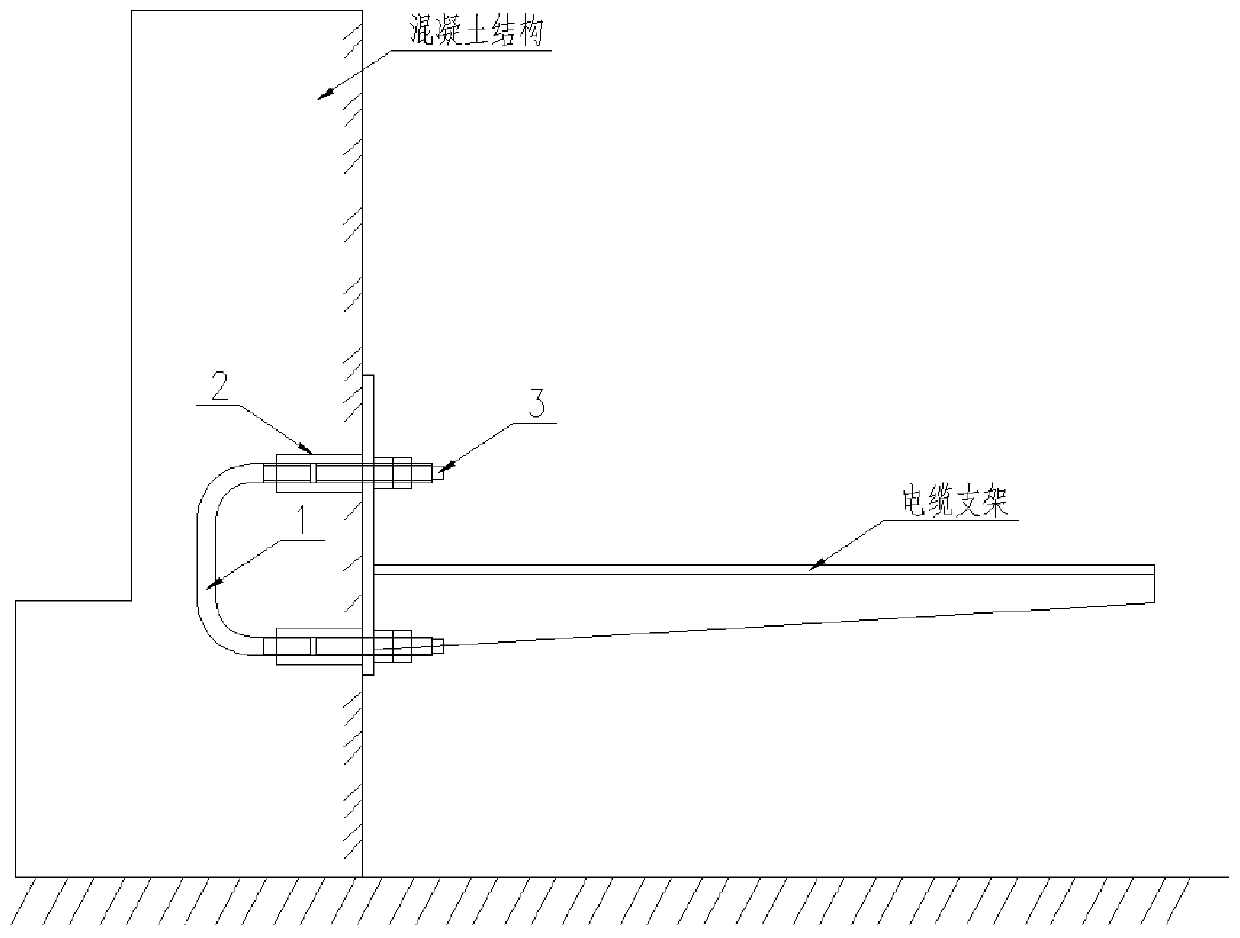

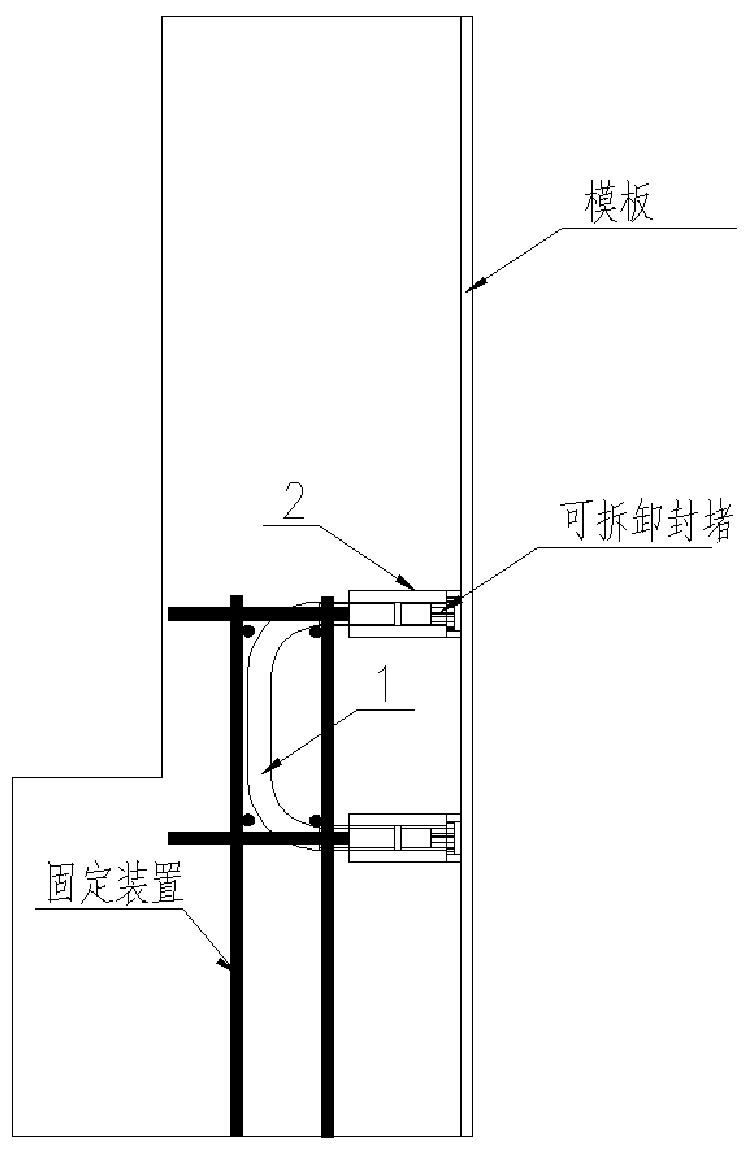

[0020] see Figure 1-3 , the embedded parts used in the laying of cable bridges in the present invention include embedded bolts 1, connecting sleeves 2 and extension bolts 3. Considering the influence of the marine environment, in order to ensure the durability of embedded parts, embedded bolts 1, connecting sleeves Both the sleeve 2 and the extension bolt 3 are made of stainless steel. The pre-embedded bolt 1 adopts a U-shaped structure, and the two ends of the U-shaped structure are processed with threads. Each end of the pre-embedded bolt 1 is matched with a connecting sleeve 2, and the two ends of the connecting sleeve 2 are also processed with threads. Cooperate, connect one end of the connecting sleeve 2 with the embedded bolt 1, and connect the other end of the connecting sleeve 2 with the threaded end of the extension bolt 3, and the other end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com