Spray rod frame of self-propelled pesticide spraying machine

A self-propelled, spraying machine technology, applied in the device, application, animal husbandry and other directions of capturing or killing insects, can solve the problems of fatigue fracture of the boom, easy contact of the boom, damage, etc., and reduce maintenance costs. , The effect of ensuring work efficiency and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

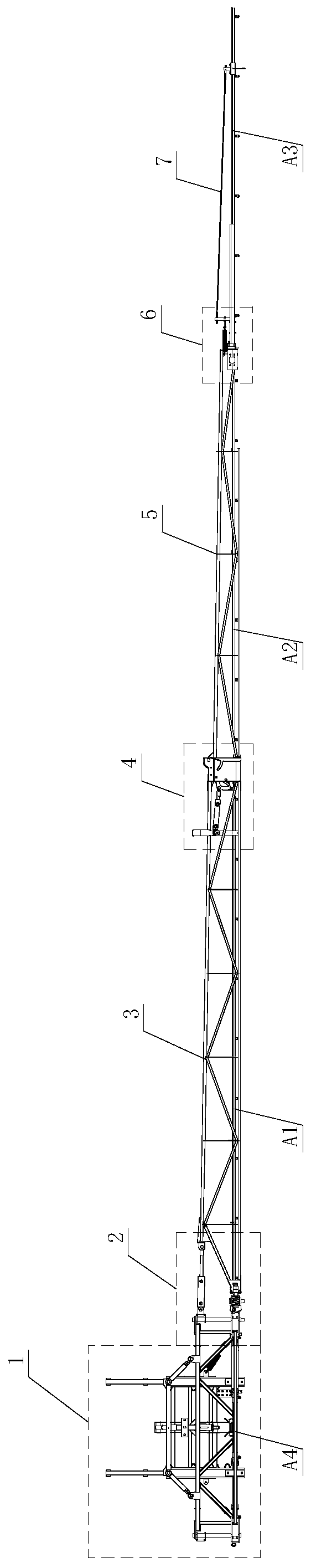

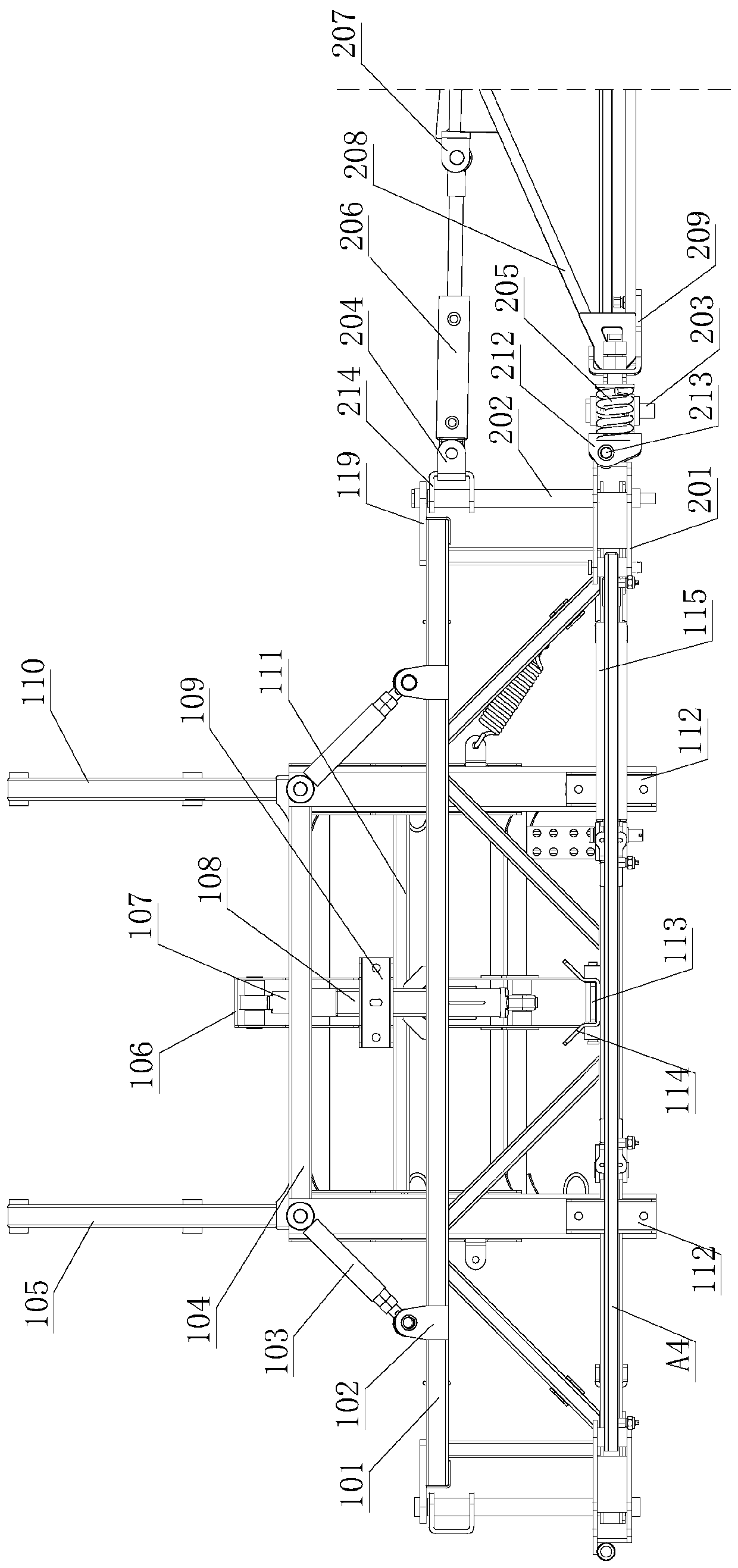

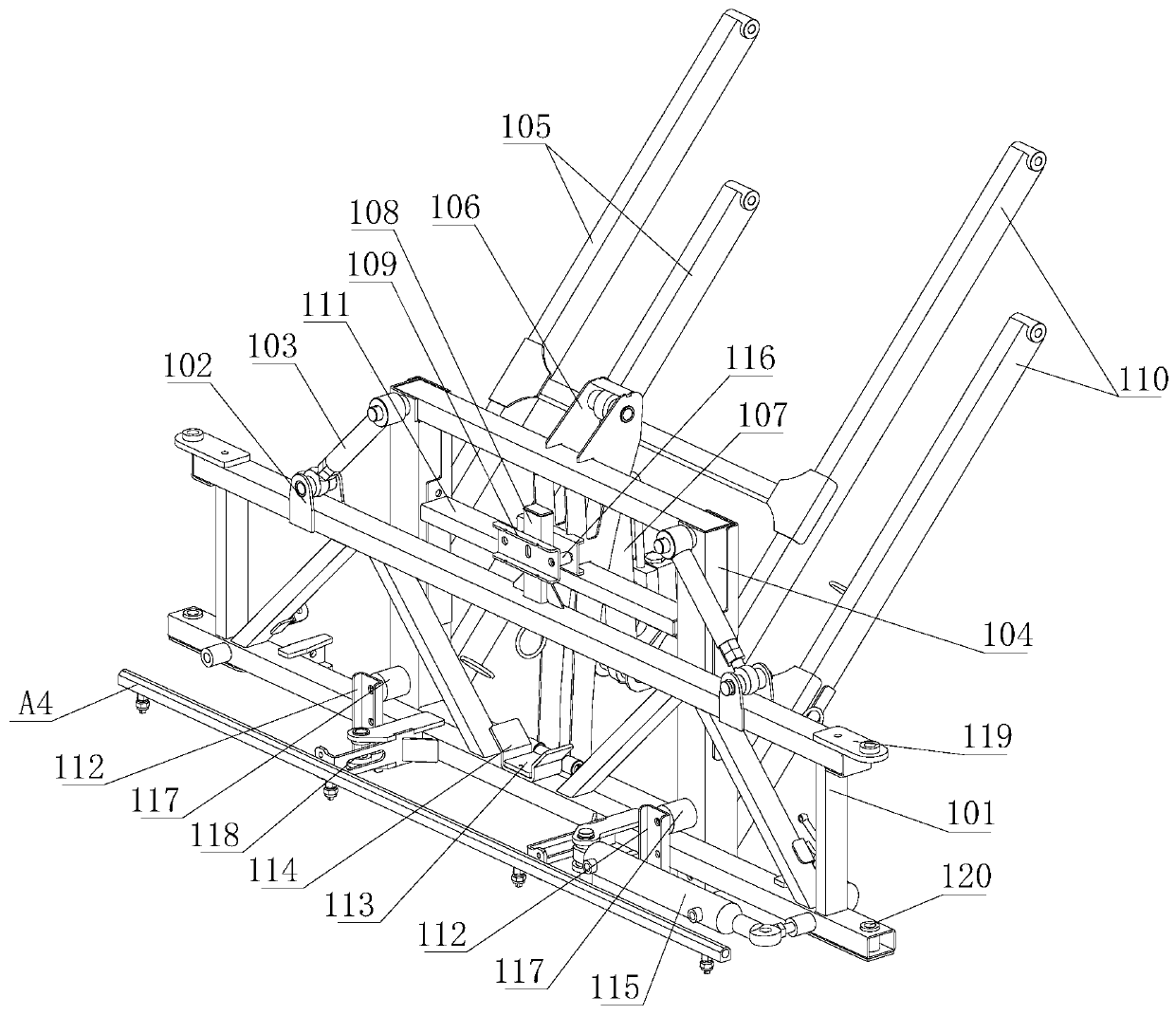

[0031] refer to figure 1, the spray boom frame of the self-propelled spraying machine described in this embodiment includes a suspension frame 1, a first side spray boom frame 3 for installing the first section of the side spray boom A1, and is installed on the suspension frame 1 and the first side The first folding mechanism 2 between the spray boom frames 3, the second side spray boom frame 5 for installing the second side spray boom A2, and the second side spray boom frame 5 installed between the first side spray boom frame 3 and the second side spray boom frame 5 The second folding mechanism 4 between them, and the third folding mechanism 6 for connecting the second section of the side spray bar A2 and the third section of the side spray bar A3; the front side of the suspension frame 1 is provided with a middle spray bar A4 The middle spray boom frame 118 of. As we all know, the spray boom frame of the self-propelled spraying machine includes a suspension frame located at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com