AGV stacking trolley with multiple cargo positions and double lateral fork entering

A double-sided, cargo space technology, applied in the direction of the lifting device, can solve the problems of tilting the direction of the trolley, waste of resources, inconvenience, etc., and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

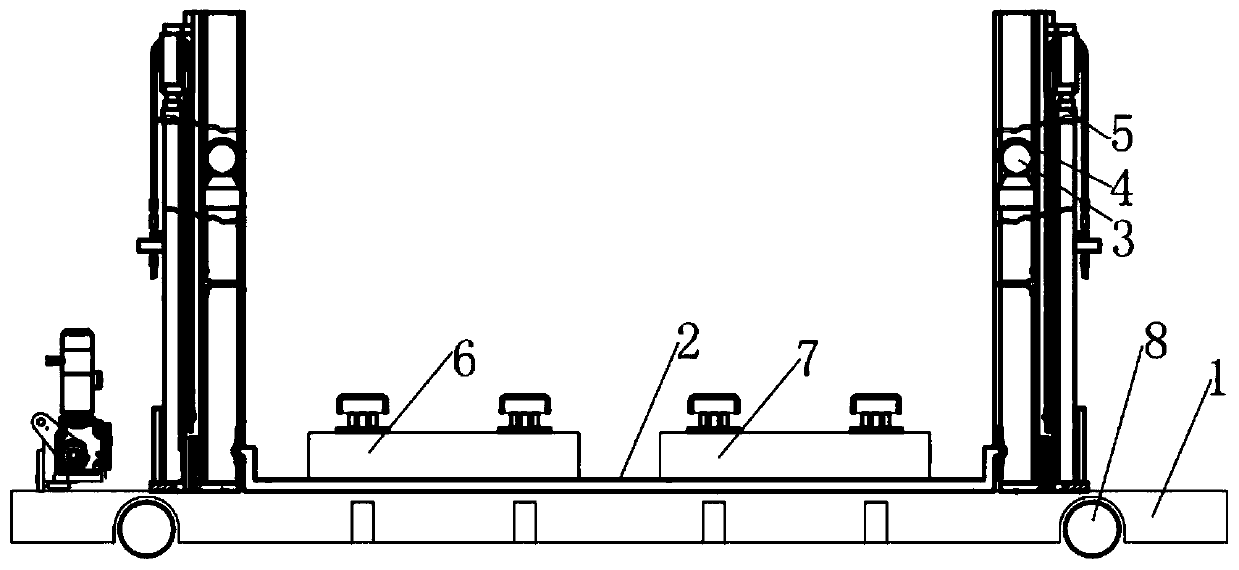

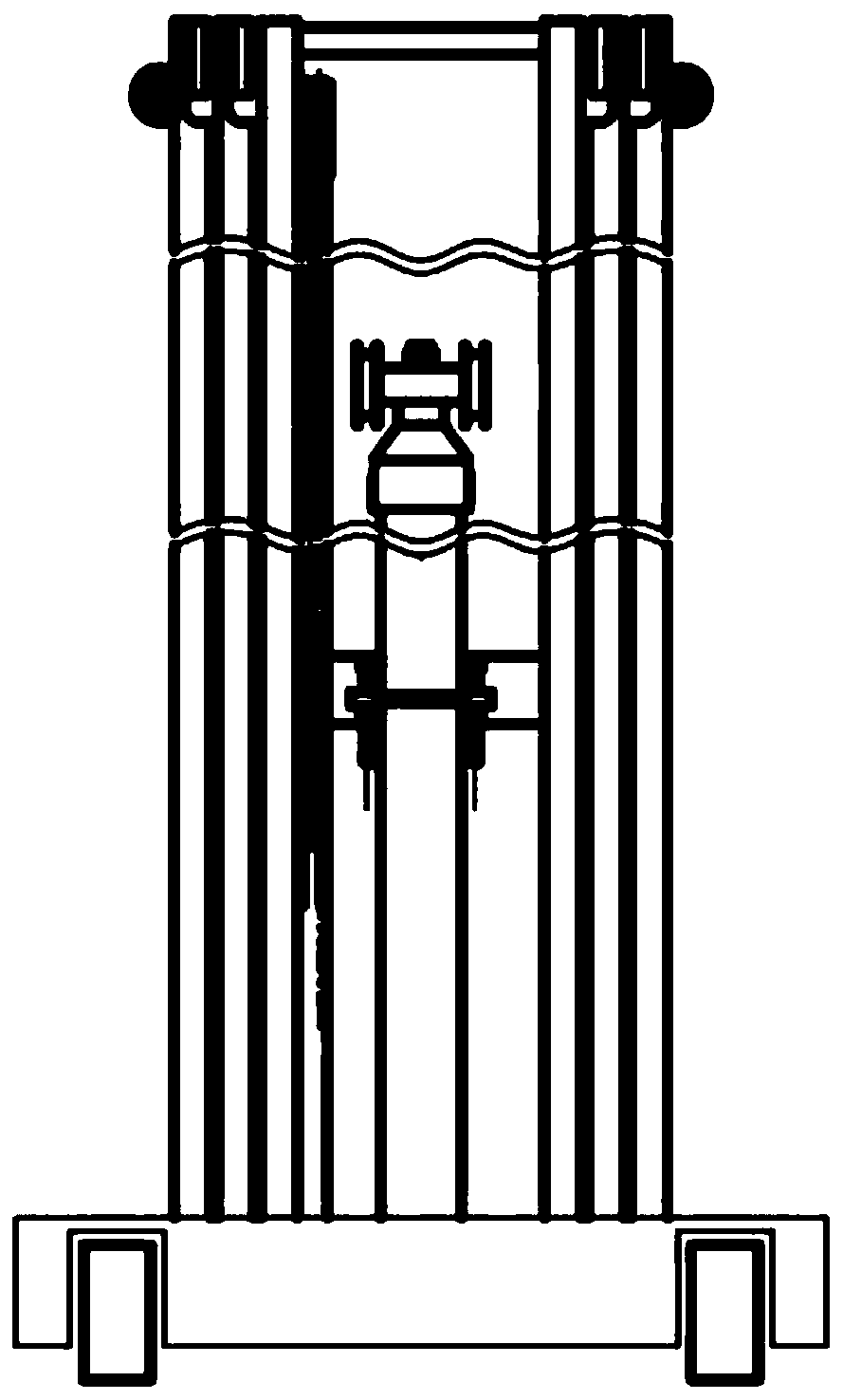

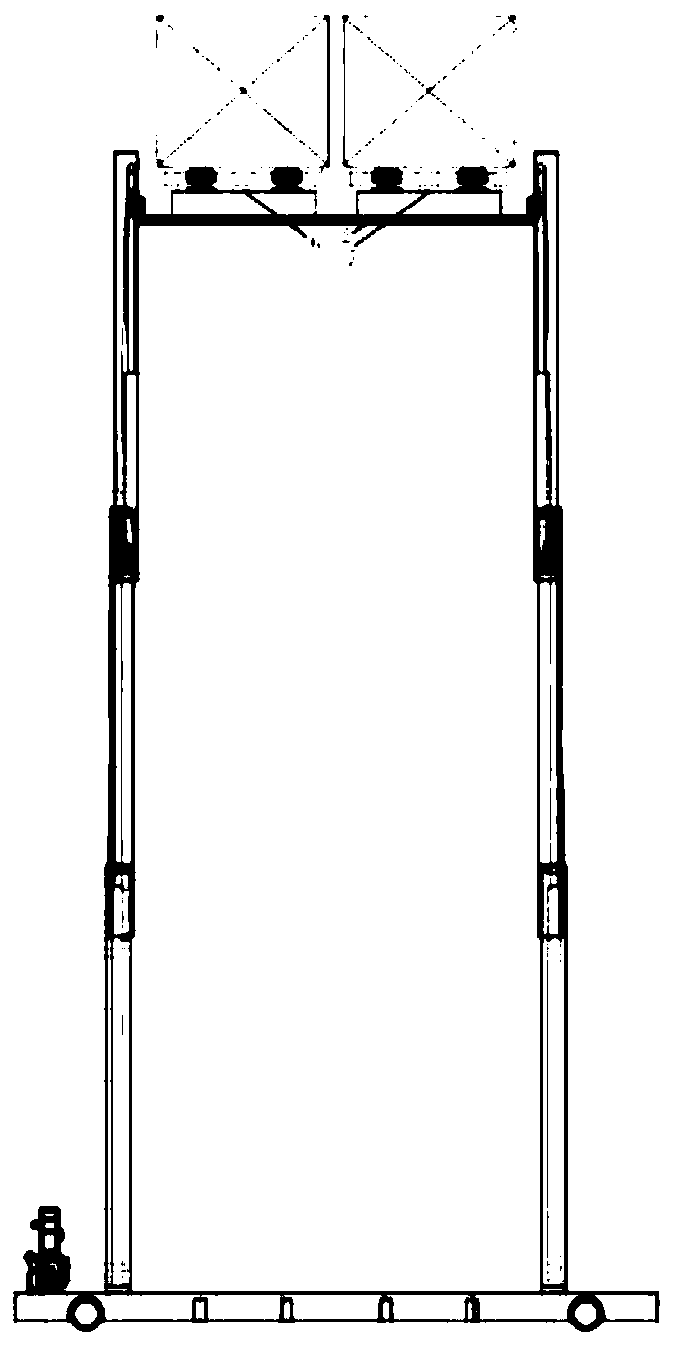

[0021] Such as Figure 1~3 As shown, a multi-position double-side fork AGV stacking trolley includes an AGV body 1, and the AGV body is provided with a lifting platform 2, and the lifting platform 2 is provided with a first cargo fork 6 and the second cargo fork 7, a synchronous mobile support leg is fixed under the AGV body, a pulley 8 is provided under the mobile support leg, and a lifting mechanism is provided on the lifting platform 2, so The lifting mechanism described above is provided with a fully free lifting cylinder 3 and a lifting cylinder 5, and the fully free lifting cylinder 3 is provided with a fully free lifting chain 4.

[0022] Further, a certain AGV counterweight is set on the AGV body 1 .

[0023] Further, the mobile supporting legs are arranged in two symmetrical groups.

Embodiment 2

[0025] Such as Figure 1~3 As shown, a multi-position double-side fork AGV stacking trolley includes an AGV body 1, and the AGV body is provided with a lifting platform 2, and the lifting platform 2 is provided with a first cargo fork 6 and the second cargo fork 7, a synchronous mobile support leg is fixed under the AGV body, a pulley 8 is provided under the mobile support leg, and a lifting mechanism is provided on the lifting platform 2, so The lifting mechanism described above is provided with a fully free lifting cylinder 3 and a lifting cylinder 5, and the fully free lifting cylinder 3 is provided with a fully free lifting chain 4.

[0026] Further, a certain AGV counterweight is set on the AGV body 1 .

[0027] Further, the mobile supporting legs are arranged in two symmetrical groups.

[0028] Further, the lifting platform 2 is used to load the steel platform of the automatic fork module, and the steel platform can be moved up and down along the inner mast of the AGV ...

Embodiment 3

[0032] Such as Figure 1~3 As shown, a multi-position double-side fork AGV stacking trolley includes an AGV body 1, and the AGV body is provided with a lifting platform 2, and the lifting platform 2 is provided with a first cargo fork 6 and the second cargo fork 7, a synchronous mobile support leg is fixed under the AGV body, a pulley 8 is provided under the mobile support leg, and a lifting mechanism is provided on the lifting platform 2, so The lifting mechanism described above is provided with a fully free lifting cylinder 3 and a lifting cylinder 5, and the fully free lifting cylinder 3 is provided with a fully free lifting chain 4.

[0033] Further, a certain AGV counterweight is set on the AGV body 1 .

[0034] Further, the mobile supporting legs are arranged in two symmetrical groups.

[0035] Further, the lifting platform 2 is used to load the steel platform of the automatic fork module, and the steel platform can be moved up and down along the inner mast of the AGV ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com