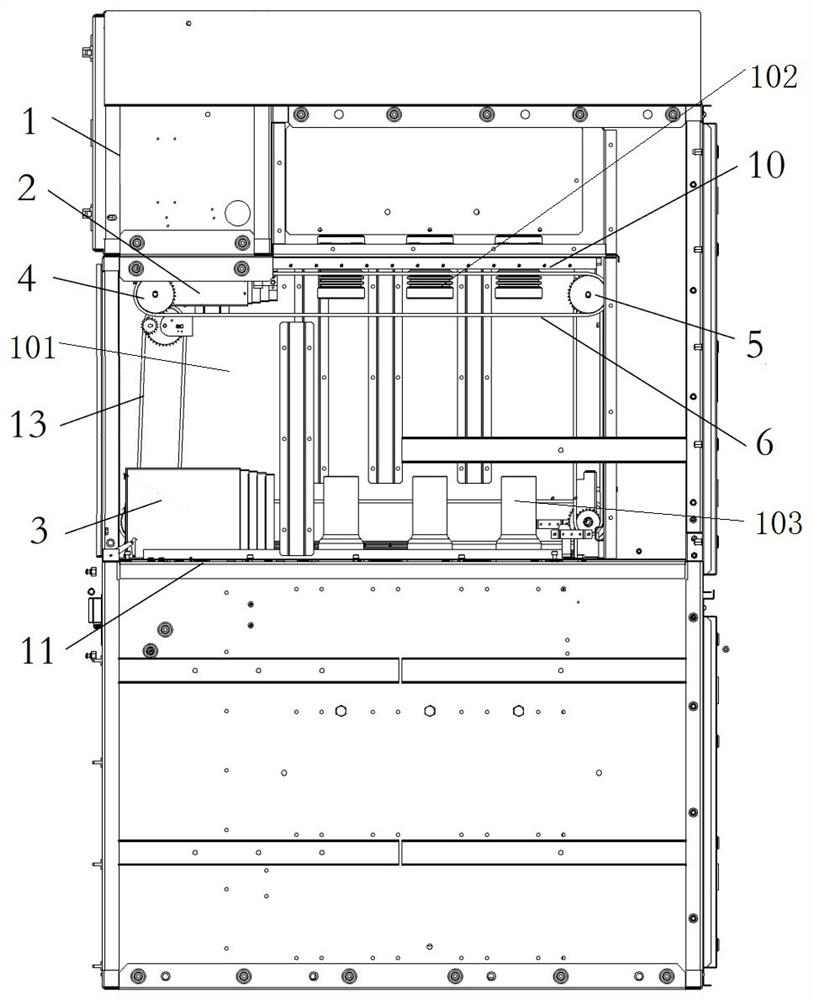

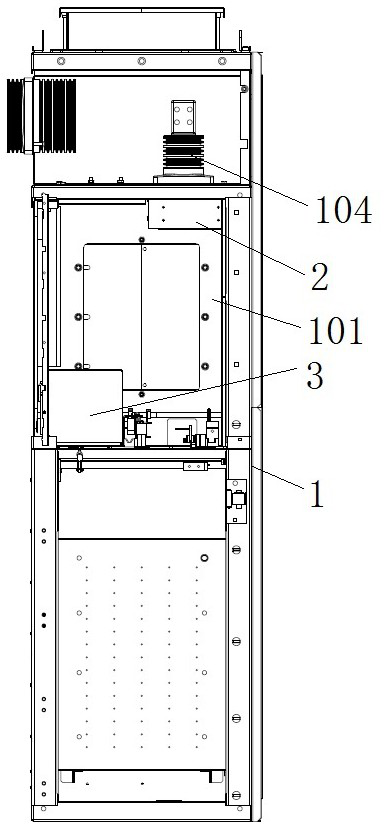

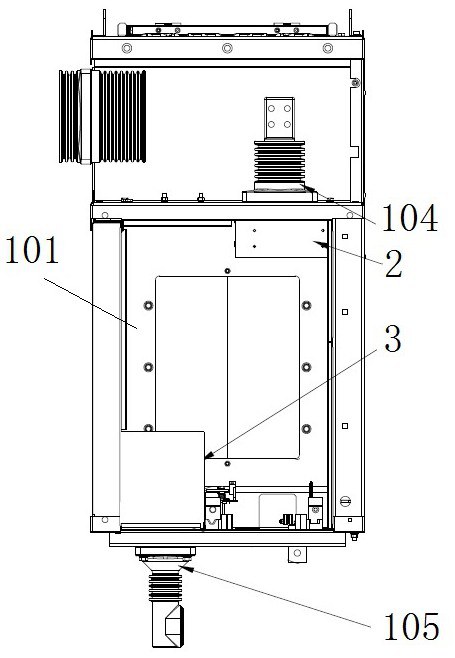

Switch cabinet and its valve linkage system

A linkage system and switchgear technology, which is applied in the direction of pull-out switchgear, switchgear, electrical components, etc., can solve the problem that the upper valve and the lower valve cannot accurately realize synchronous movement, and achieve convenient design and installation, and simple transmission connection structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

[0048] Specific embodiment 2 of the switchgear of the present invention, the switchgear includes a cabinet body and a circuit breaker room arranged in the cabinet body, the valve linkage system is arranged in the circuit breaker room, and the valve linkage system includes The upper valve device and the lower valve device, the upper valve device and the lower valve device both include a telescopic valve structure, and a synchronous transmission mechanism is provided between the two valve devices to drive the synchronous telescopic action of the two telescopic valve structures. The synchronous telescopic action of the upper valve device and the lower valve device is driven by the synchronous transmission mechanism, which realizes the synchronous movement of the upper valve and the lower valve, and solves the problem in the prior art that the upper valve and the lower valve drive system drive the valve to open and close separately. The problem that the upper valve and the lower va...

specific Embodiment 8

[0054] The specific embodiment 8 of the switchgear of the present invention, as a further optimization of any one of the specific embodiments 2 to 6 of the switchgear of the present invention, considering that the opening of the valve by misoperation will affect the personal safety of maintenance personnel, this embodiment The valve linkage system in the valve also includes an interlock device that restricts the action of the upper valve device and the lower valve device in the closed state.

[0055] The specific embodiment of the valve linkage system of the present invention, the structure of the valve linkage system in this embodiment is the same as the valve linkage system described in any one of the specific embodiments 1 to 8 of the above-mentioned switchgear, and will not be described again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com