Groove inserting lattice member combination checkerboard structure

A lattice member and chessboard technology, which is applied in the field of slot-inserted lattice member combined chessboard structure, can solve the problems of unsmooth sliding of chess pieces, poor track groove smoothness, time-consuming and labor-intensive, etc., and achieves flexible organization and capacity, improved installation accuracy, and simple and flexible assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

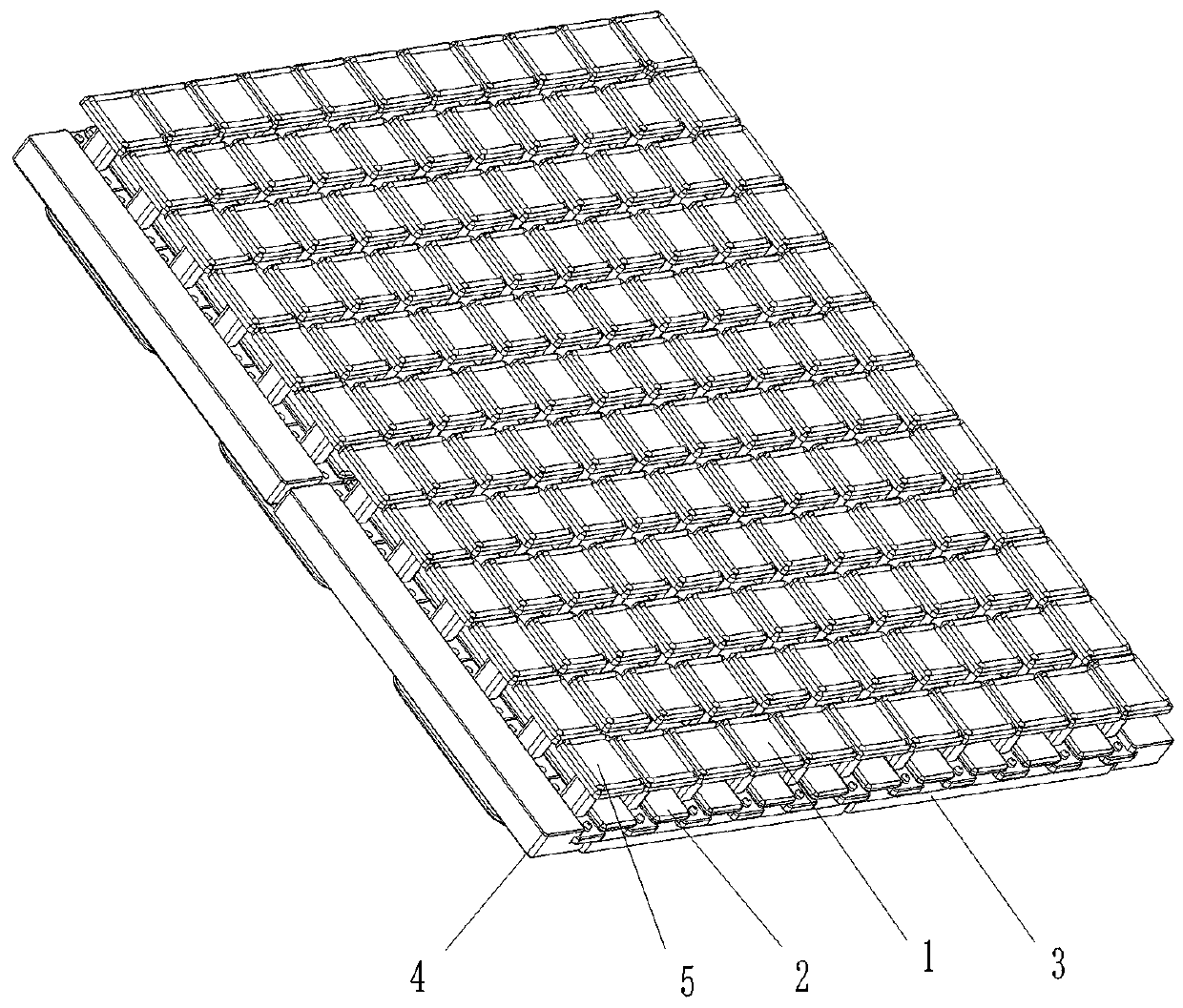

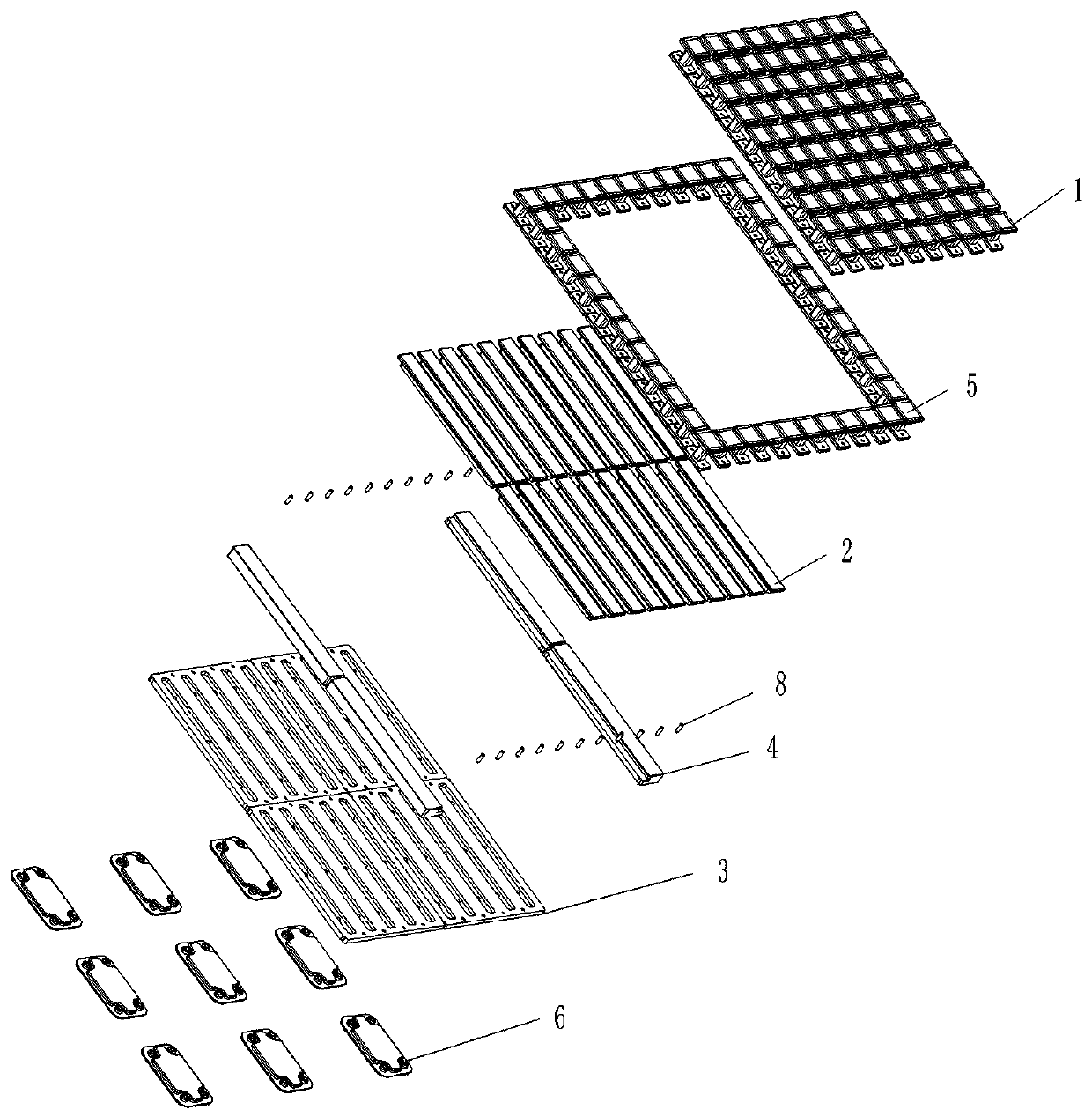

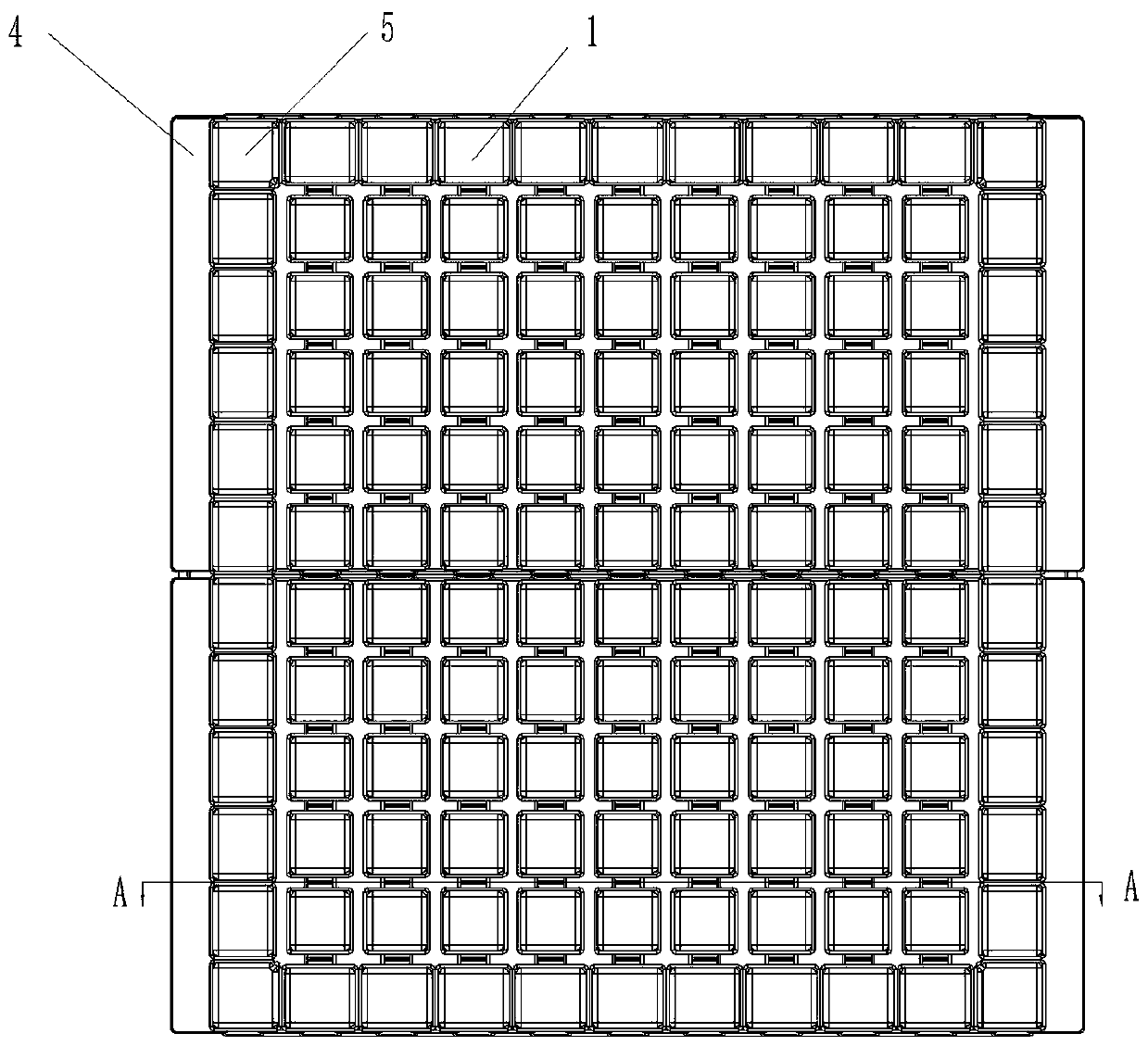

[0030] The present invention will be described in detail below in combination with specific embodiments.

[0031] The present invention relates to a combination checkerboard structure of slotted and lattice components, which comprises a mounting base plate 3, on which a plurality of parallel bead grooves 9 are arranged, and lattice components 1 longitudinally arranged in columns between adjacent bead grooves 9; 1 From top to bottom, it includes a top cover 12, a connecting column 13 and a chassis 14. The vertical section is I-shaped, and an inverted T-shaped track groove is formed between vertically and horizontally adjacent grid members 1; The bead 2, the vertical section of the bead 2 is T-shaped, the chassis 14 of the lattice member 1 is pressed at both ends, and the bottom is inserted in the bead groove 9.

[0032] Be provided with bead fixing hole 10 in the bead groove 9 of base plate 3, be provided with corresponding screw hole at the bottom of bead 2, bead 2 is fixed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com