An automatic detection mechanism and method for the fixity of connector positioning claws

An automatic detection and positioning claw technology, which is applied in the testing of machines/structural components, instruments, measuring devices, etc., can solve the problems of cumbersome operation and unquantifiable pulling force, and achieve the effect of quantifying force measurement and preventing crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

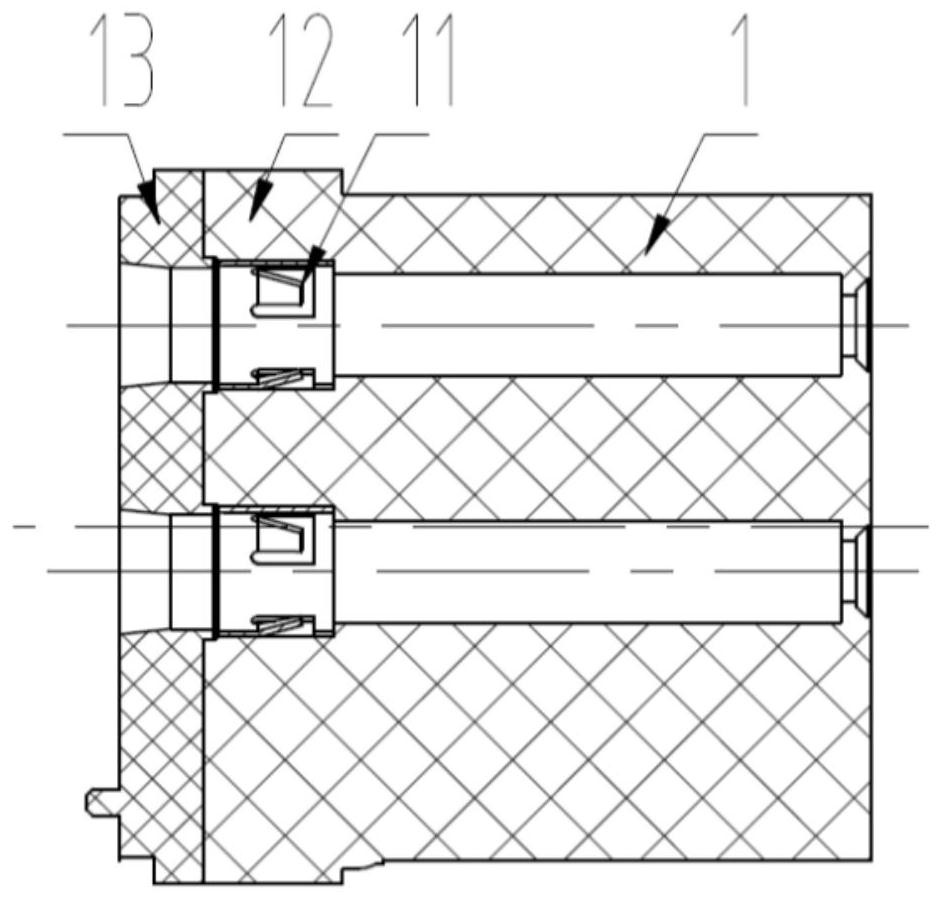

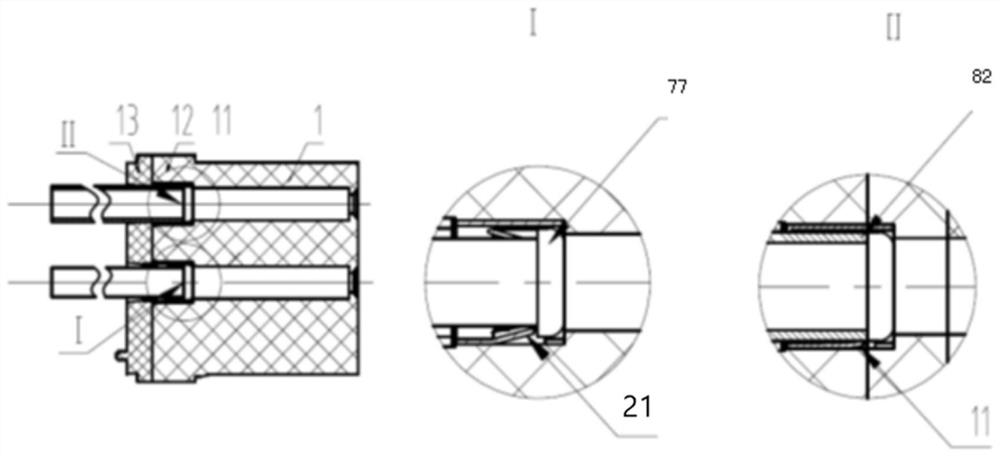

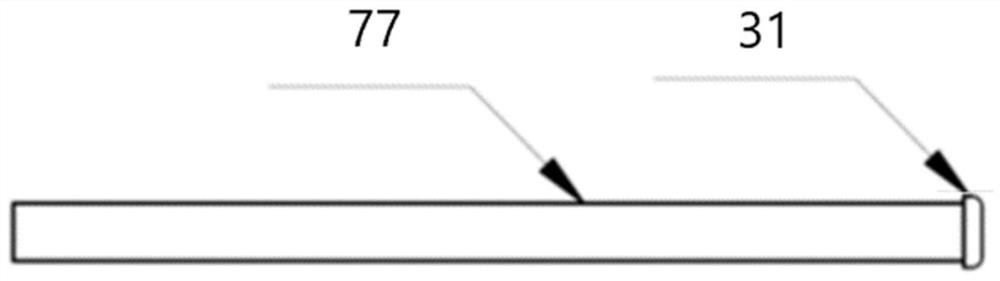

[0033] An automatic detection mechanism for the fixity of connector positioning claws, such as Figure 9 As shown, including the force measuring base 5, the right positioning assembly 6, the force measuring assembly 7, and the left sleeve pushing assembly 8, before starting the test, the right positioning assembly 6, the force measuring assembly 7, and the left sleeve pushing assembly 8 are all set in the Including the wire track 58 on the force-measuring base 5 for installation, the force-measuring component 7 is located in the middle of the force-measuring base 5, hung on the first fixing bracket 50 by the hook 71, fixed by the second fixing bracket 53, and the left sleeve pushes the component 8 and the right positioning component 6 are respectively located on the left and right sides of the force measuring base 5, and are fixed by the sliding block 55, and can move up and down on the line rail 58. The right positioning component 6 is used to prevent the force measuring compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com