Particle damping and shock absorbing end cover and main generator using the end cover

A particle damping and end cover technology, applied in the field of shock absorption, can solve problems affecting bearing life and normal operation, and achieve the effect of reducing motor vibration and wide application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

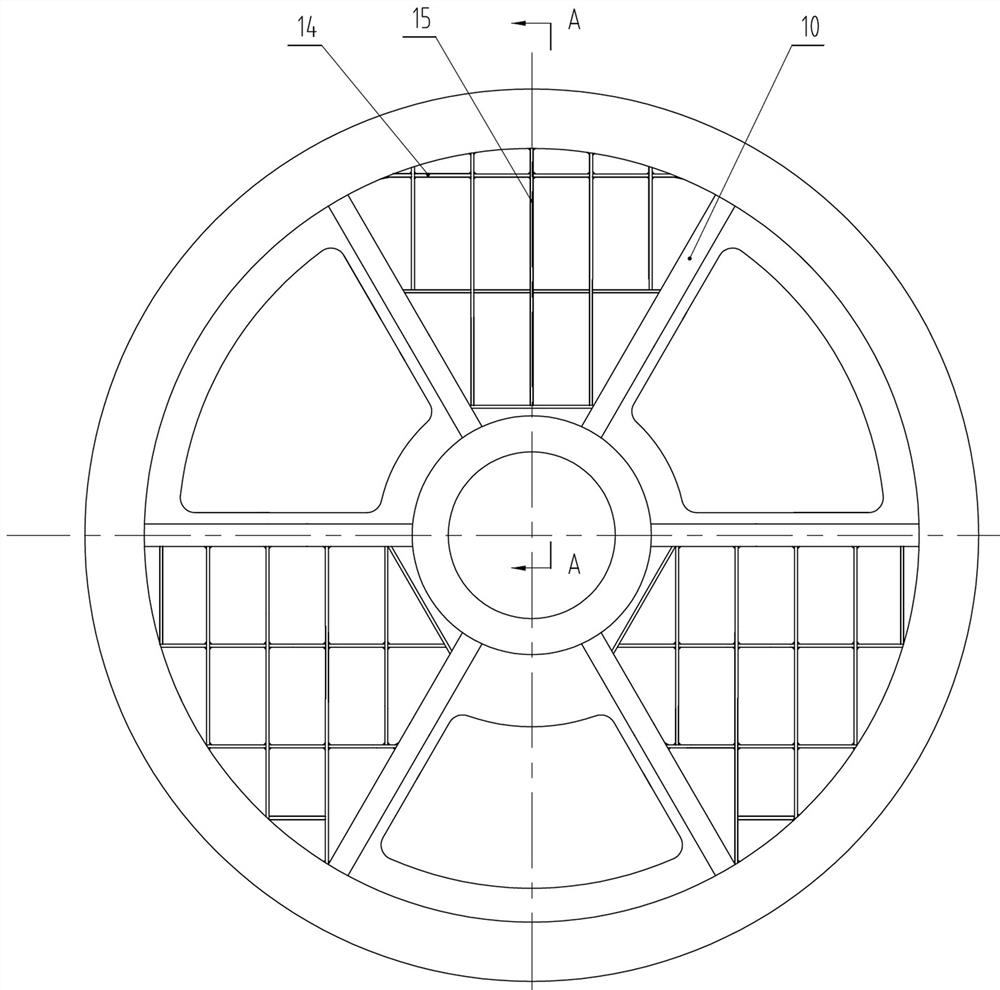

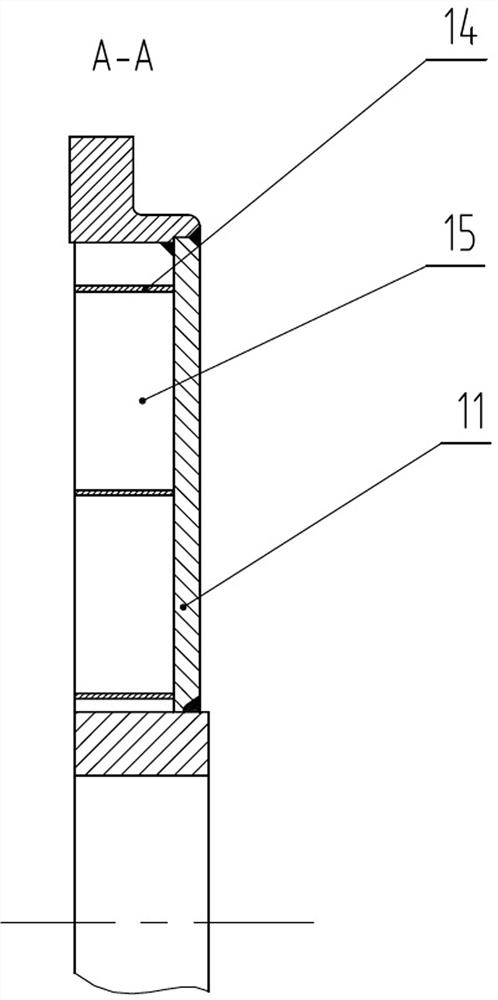

[0036] In the three vacancies between the six stiffener plates 10 inside the generator end cover, a plurality of cavities separated by baffle plates (most of which are rectangular, and there are other shapes at the edges) are designed to connect the horizontal plate 14 and the vertical plate 15 spot welded between the side plate 11 and the rib plate 10 of the end cover. The spacing and height of each plate are equal, and the direction is also designed to be vertical. Such as figure 1 , 2 shown.

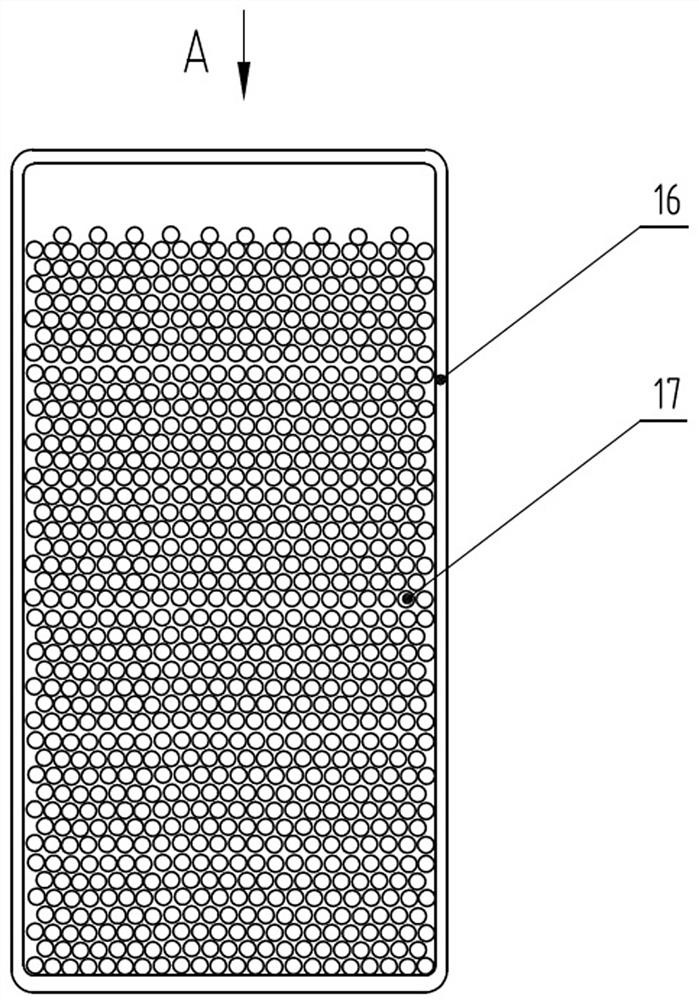

[0037] Select industrial nylon Oxford cloth 16 with excellent mechanical properties such as tensile, flexural, scratch-resistant, and tear-resistant, and then use high-strength tensile and wear-resistant thread (PE braided thread or Dynema thread) to sew it into a cylindrical cloth bag. The bag diameter and the spacing of the riser 15 remain the same.

[0038] Spherical steel ball 17 particles are packed in the cloth bag, and the filling amount accounts for about 85% of the heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com