Super-long concrete structure crack control method and structure

A concrete structure and control method technology, which is applied to building components, building structures, wine cellars, etc., can solve problems such as uncoordinated deformation of components, and achieve the effects of improving constraints, reducing temperature stress, and alleviating cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

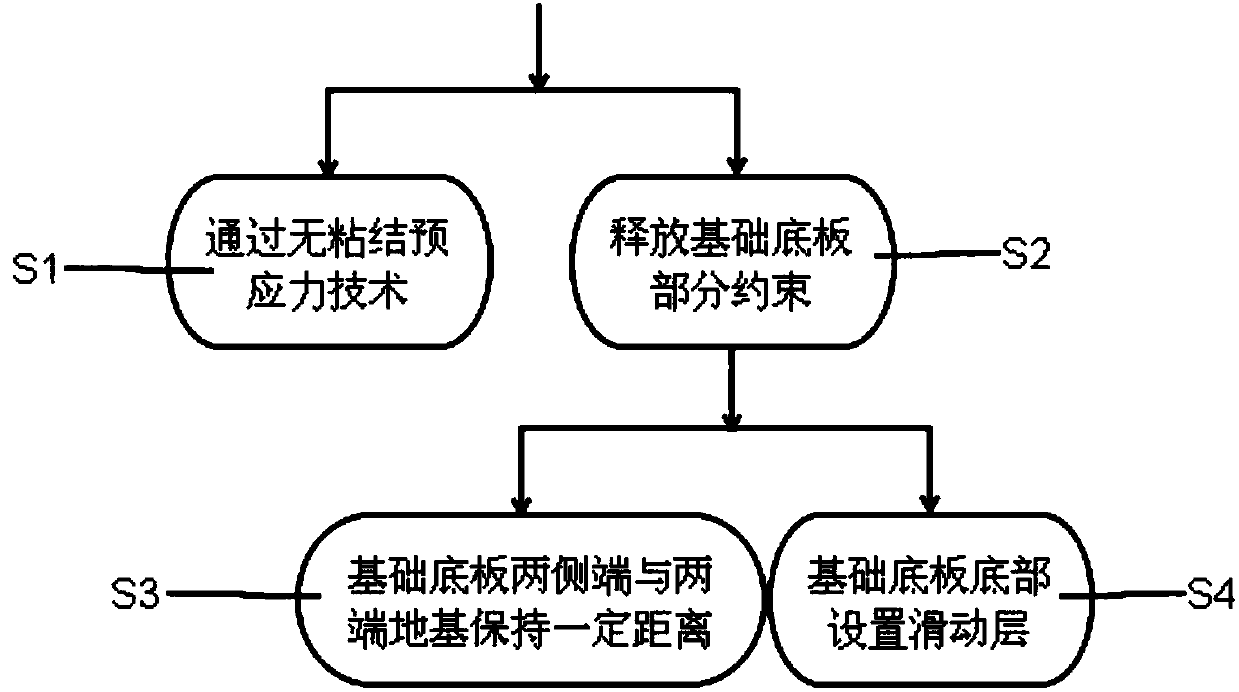

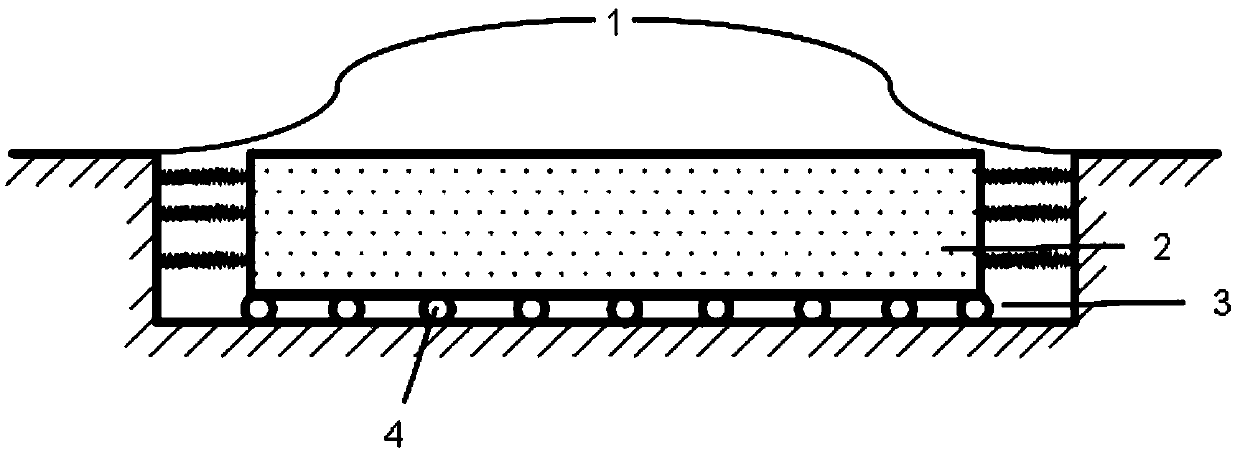

[0024] This embodiment: as figure 1 As shown, a method for controlling cracks in super-long concrete structures, the method includes releasing the partial constraint S2 of the base plate 2 through the unbonded prestressing technology S1.

[0025] Due to the use of unbonded prestressing technology to release part of the constraints of the foundation floor, due to the use of unbonded prestressing technology to control the cracking of super-long concrete structures, different sizes of prestress are applied to different directions of the structure to control temperature stress. The deformation characteristics and internal force changes of the structure under the action of uniform seasonal temperature difference are analyzed, and the "breathable" system is proposed to control the cracks of the super-long concrete structure. When the partial restraint of the bottom plate is released, the structure can expand and contract freely under the action of temperature shrinkage, and the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com