Water storage structure of washing machine and washing machine with water storage structure

A washing machine and water storage technology, which is applied to the control device of washing machine, other washing machines, washing devices, etc., can solve the problems of foam backflow, outflow, and potential safety hazards of electrical components, and achieves small changes, good integration effect, and avoidance of potential safety hazards. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

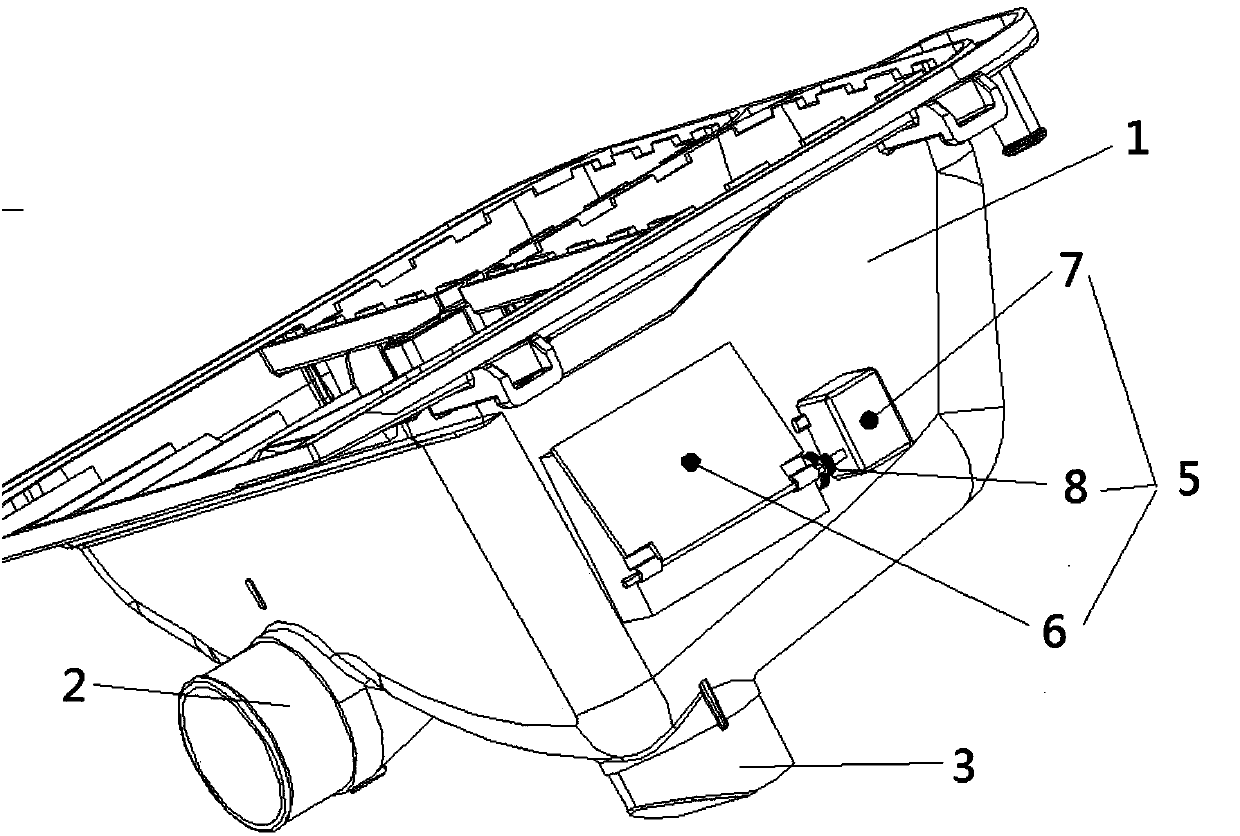

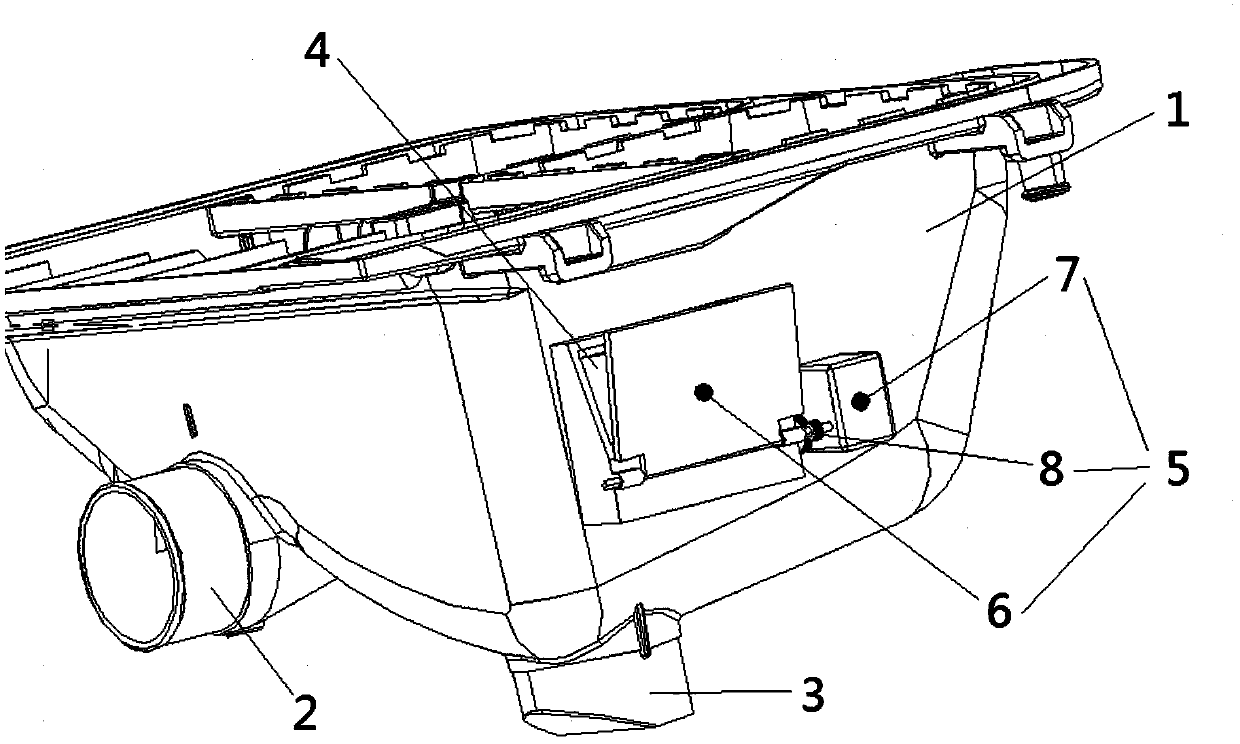

[0062] Such as Figure 1 to Figure 2 As shown, the water storage structure of a washing machine described in this embodiment includes a water storage tank 1, and at least one water outlet is arranged on the water storage tank 1; specifically, the water outlet of the water storage tank 1 in the present invention includes a first The water outlet 2 and the second water outlet 3, wherein the first water outlet 2 is the water outlet connected to the water storage tank 1 and the upper cylinder, and the second water outlet 3 is the water outlet connected to the water storage tank 1 and the lower cylinder. It can also be equipped with a detachable dispenser. The dispenser is equipped with a main washing box for storage of granular additives, a softener box for storage of liquid softener, and is used for pre-washing when the clothes are particularly dirty and need to be pre-washed. Additive pre-washing boxes, etc. Of course, those skilled in the art can make corresponding structural a...

Embodiment 2

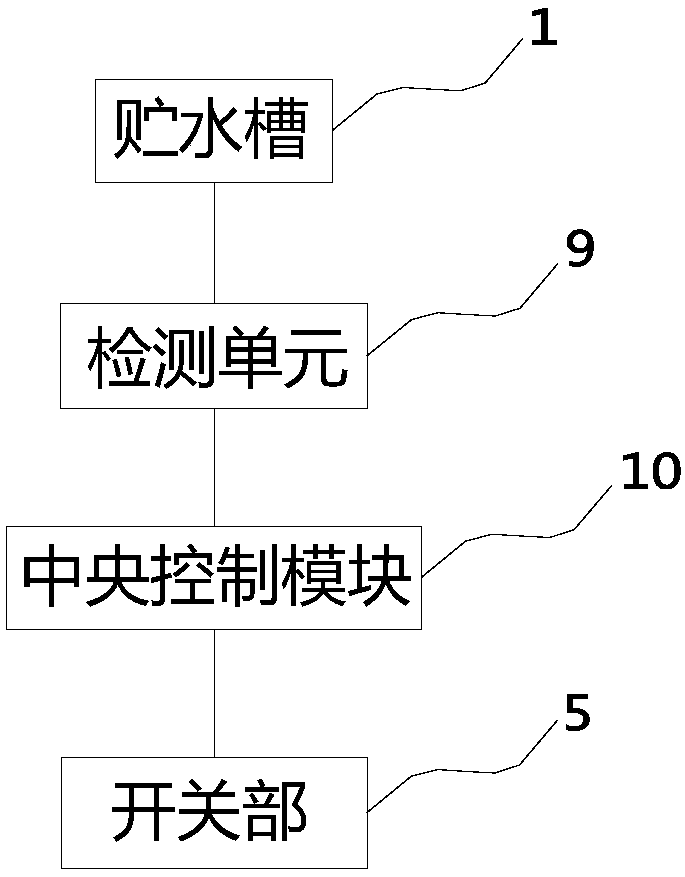

[0066] Such as Figure 1 to Figure 2 As shown, this embodiment is a further limitation of the first embodiment above. The water storage structure of a washing machine described in this embodiment includes a water storage tank 1, and at least one water outlet is arranged on the water storage tank 1; On the side wall of the water storage tank 1, it is configured to prevent backwashing of the washing water inside the water storage tank 1, and also includes a switch part 5, which is arranged at the overflow port 4, and is configured to open or close the overflow port 4, thereby blocking excess water in the water storage tank 1. The foam flows out from the overflow port 4.

[0067] Wherein, the switch part 5 includes a first switch unit 6 arranged outside the overflow port 4 to at least partially open or close the overflow port 4; and a second switch unit 7 that drives the first switch unit 6 to open or close the overflow port 4, Those skilled in the art can use the first switch u...

Embodiment 3

[0071] Such as Figure 1 to Figure 2 As shown, this embodiment is a further limitation of the first embodiment above. The water storage structure of a washing machine described in this embodiment includes a water storage tank 1, and at least one water outlet is arranged on the water storage tank 1; On the side wall of the water storage tank 1, it is configured to prevent backwashing of the washing water inside the water storage tank 1, and also includes a switch part 5, which is arranged at the overflow port 4, and is configured to open or close the overflow port 4, thereby blocking excess water in the water storage tank 1. The foam flows out from the overflow port 4.

[0072] Wherein, the switch part 5 includes a first switch unit 6 arranged outside the overflow port 4 to at least partially open or close the overflow port 4; and a second switch unit 7 that drives the first switch unit 6 to open or close the overflow port 4, Those skilled in the art can use the first switch u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com