Deep vertical displacement monitoring point device

A technology of vertical displacement and monitoring points, applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve the problems of affecting the observation accuracy of soil settlement, reducing construction efficiency, troublesome backfilling and compaction, and achieving difficult monitoring deviation and connection. Easy to operate and achieve the effect of synchronous settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

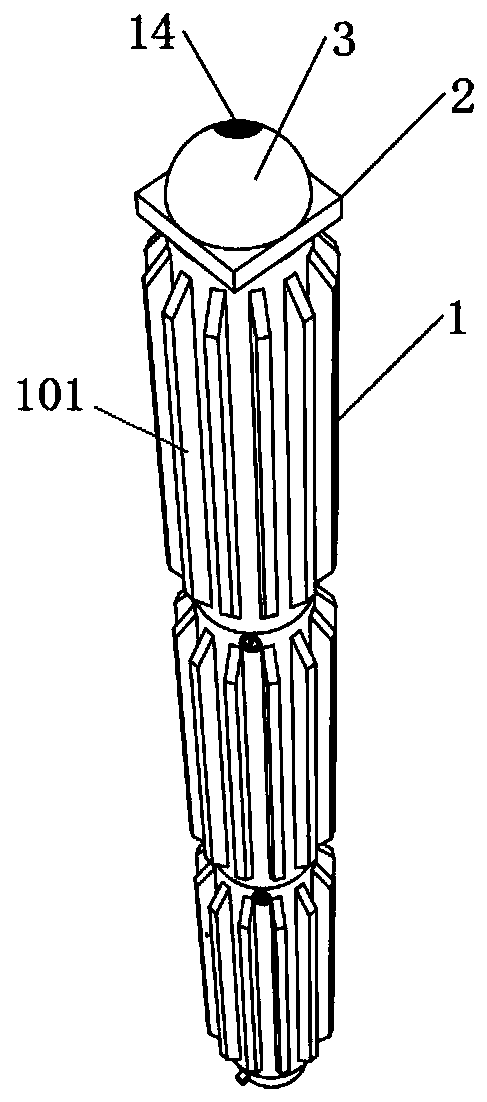

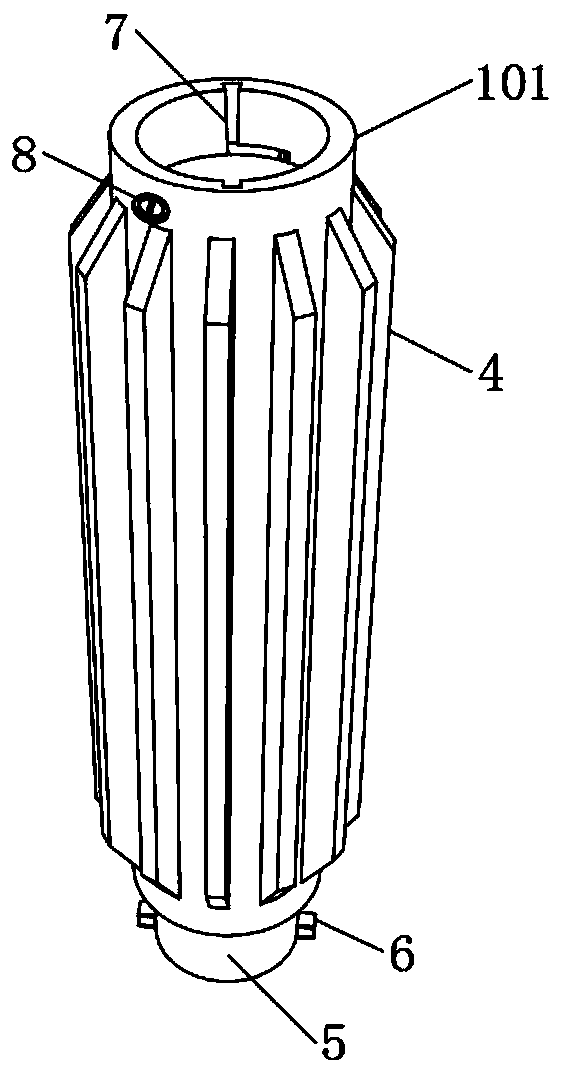

[0035] see Figure 1-5 , a deep vertical displacement monitoring point device, including a probe device and a measuring rod 1, the measuring rod 1 includes at least one sub-rod 101, and the axial ends of the sub-rod 101 are respectively provided with a docking port and a docking platform 5. The probe device is provided with a docking port or a docking platform 5, and the connection between the probe device and the adjacent sub-rods is realized through the cooperation of the docking port and the docking platform 5. Multiple sub-rods 101 are coaxially arranged and passed through the corresponding The cooperation between the docking ports between the adjacent sub-poles and the docking platform 5 realizes the end-to-end sequential connection;

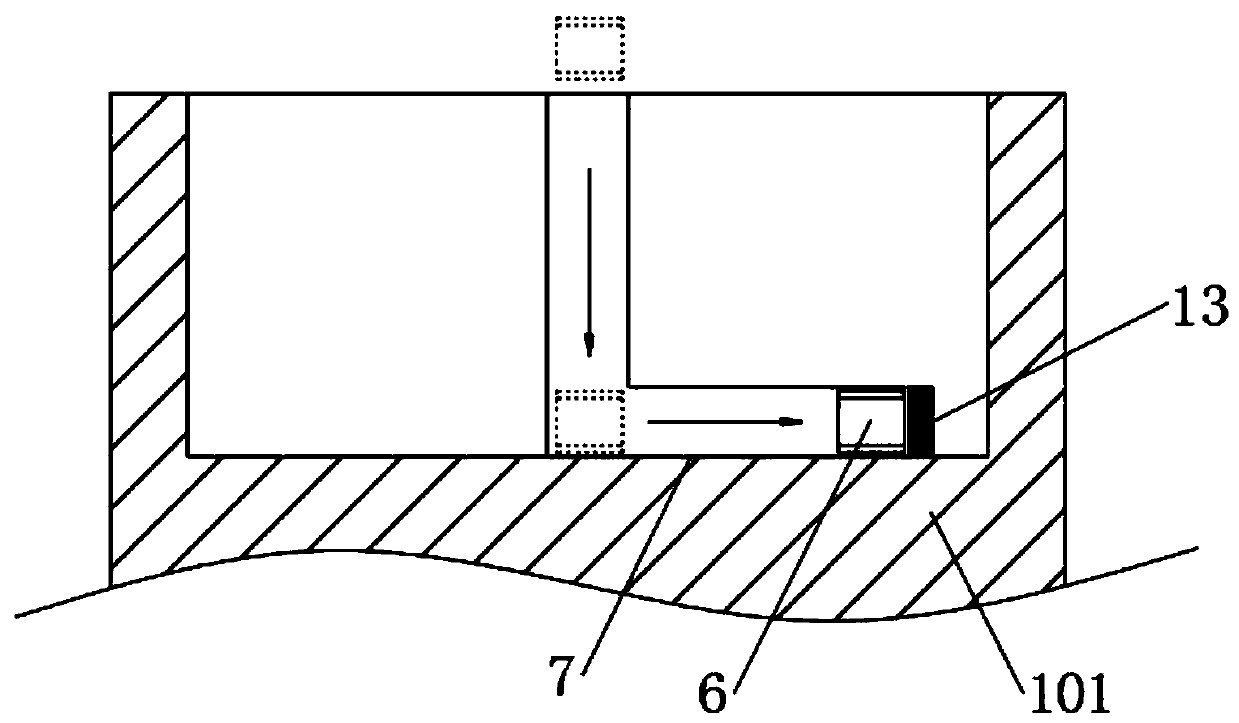

[0036] see figure 2 with image 3 , the inner wall of the docking port is provided with at least one lock slot 7, the outer wall of the docking table 5 is provided with a displacement lock block 6 matching the lock slot, the docking tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com