Dry type cleaning machine

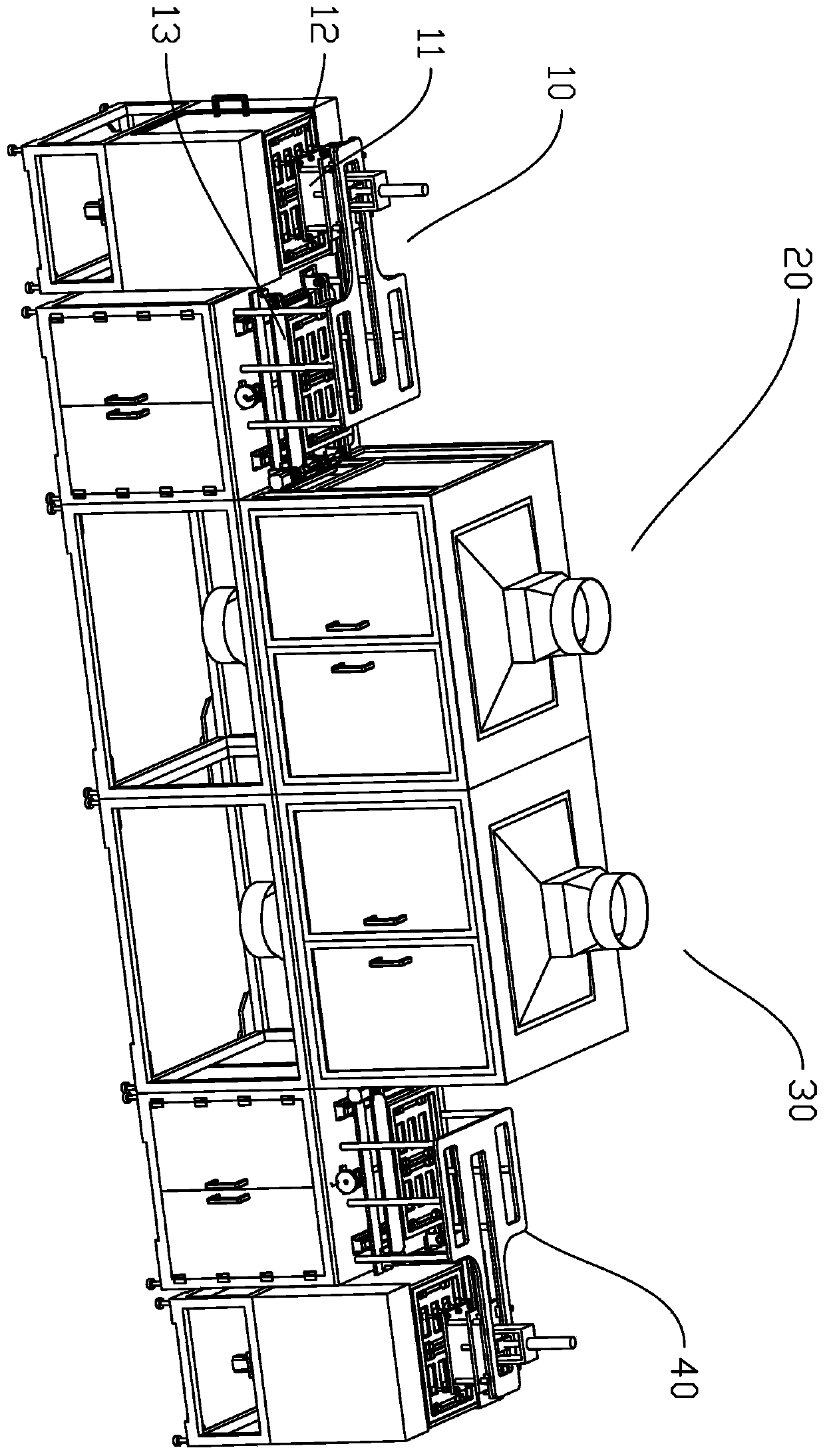

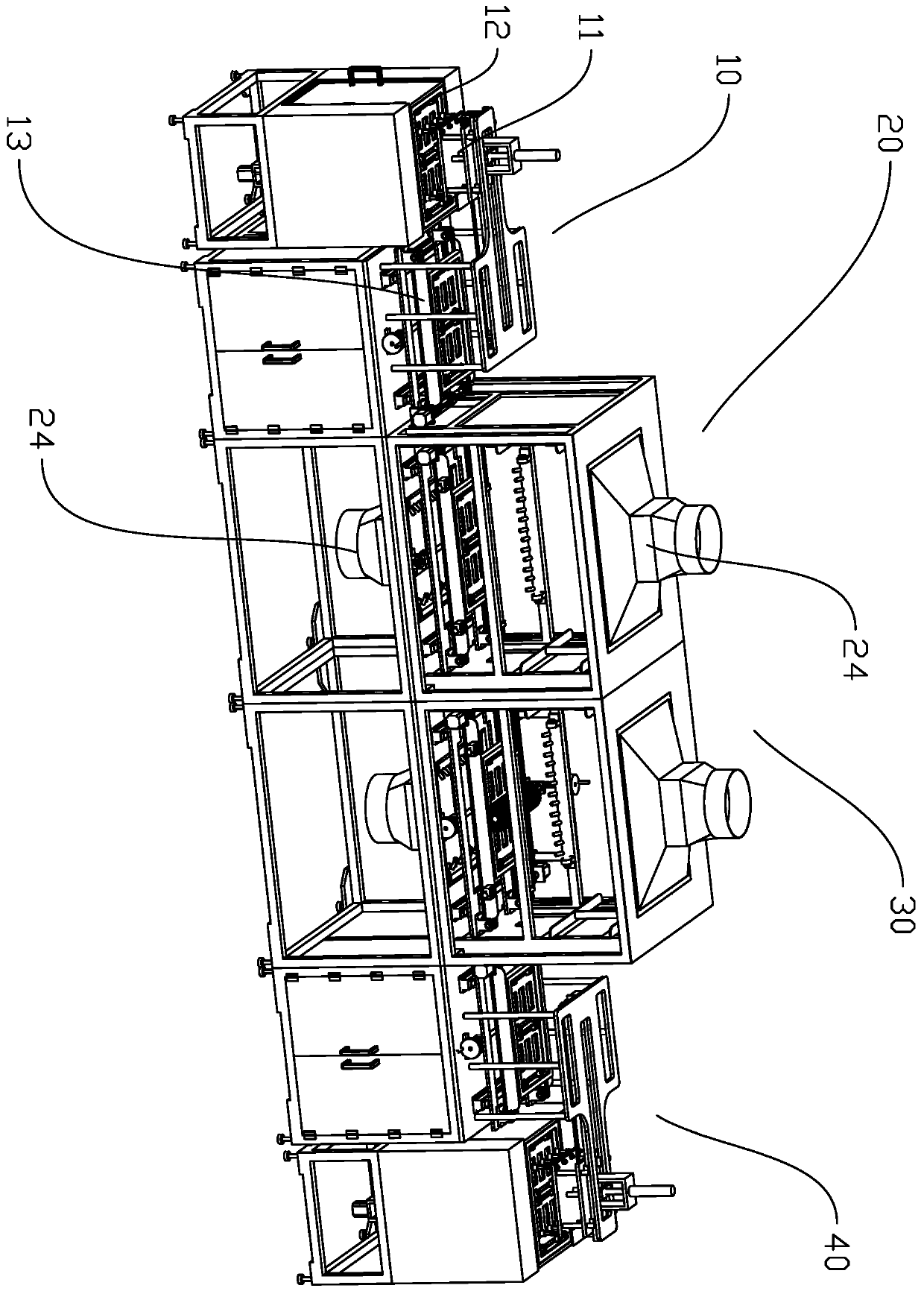

A dry cleaning machine and cleaning machine technology, applied in the field of cleaning, can solve the problems of inadequate cleaning of containers, large manpower consumption, high cost, etc., achieve standardized cleaning, save labor costs, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

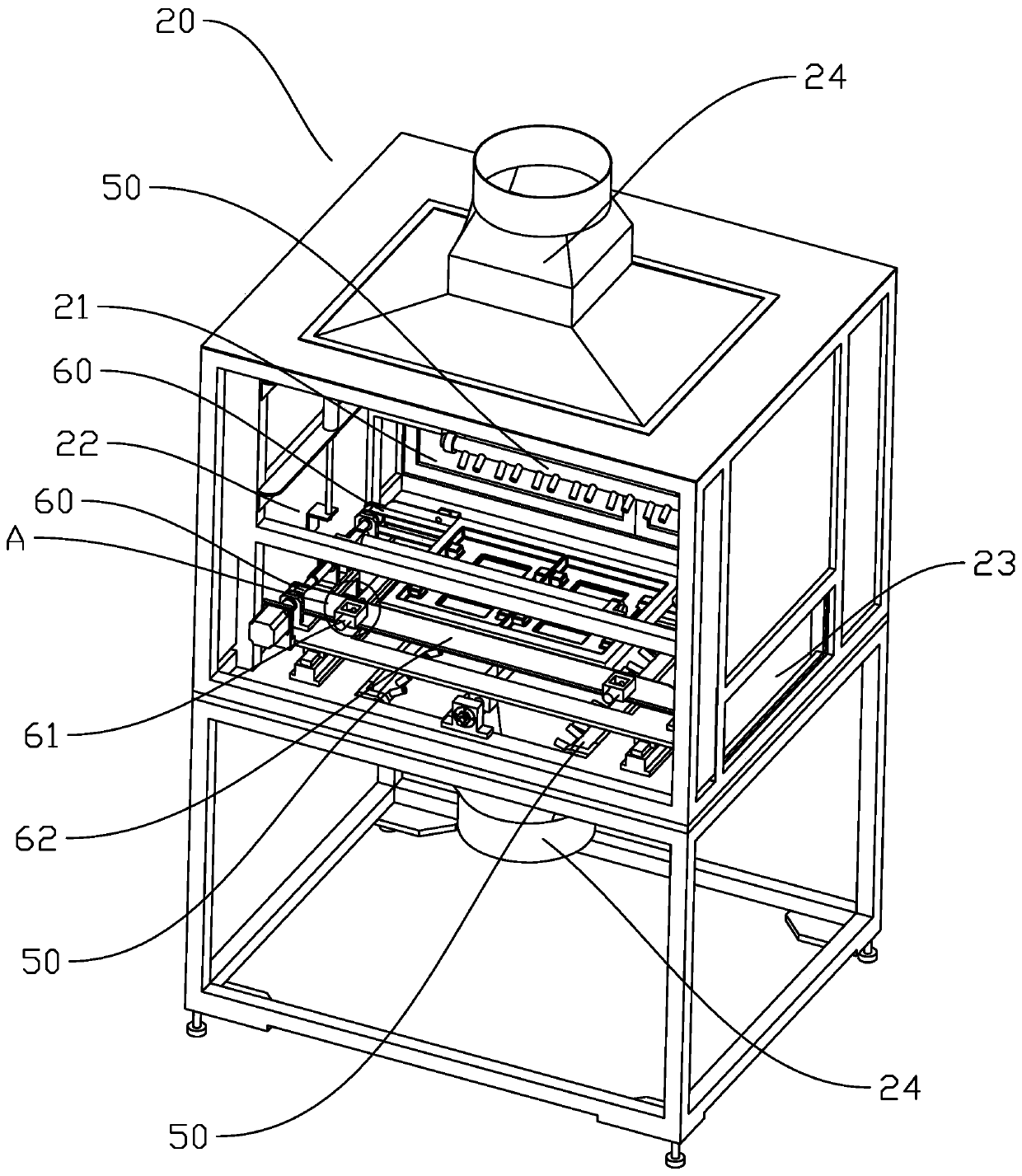

[0050] To further illustrate, the first delivery device and the second delivery device can choose the same implementation mode during use, preferably including:

[0051] Two transportation lines 60, the two transportation lines 60 are arranged oppositely and move in the same direction, a gap for placing objects is formed between the two transportation lines 60, and the two transportation lines 60 are respectively used for carrying and towing the two ends of the object;

[0052] An adjustment device 63 , the adjustment device 63 is arranged between the two transportation lines 60 , and the adjustment device 63 is used for adjusting the distance between the two transportation lines 60 .

[0053] The adjustment device 63 has multiple options, such as a double-ended screw connecting the two transportation lines 60 between the two transportation lines 60, and an adjustment handwheel is arranged at one end of the double-ended screw. The wheel can drive the double-ended screw to rota...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap