Deep tunnel oxygen-rich air circulation system

An oxygen-enriched gas and circulation system technology, which is applied in the ventilation of mines/tunnels, mining equipment, mining equipment, etc., can solve the problems that harmful gases cannot be effectively discharged, endanger the health of workers, etc., and reduce the area of diffuse oxygen supply , the effect of reducing dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

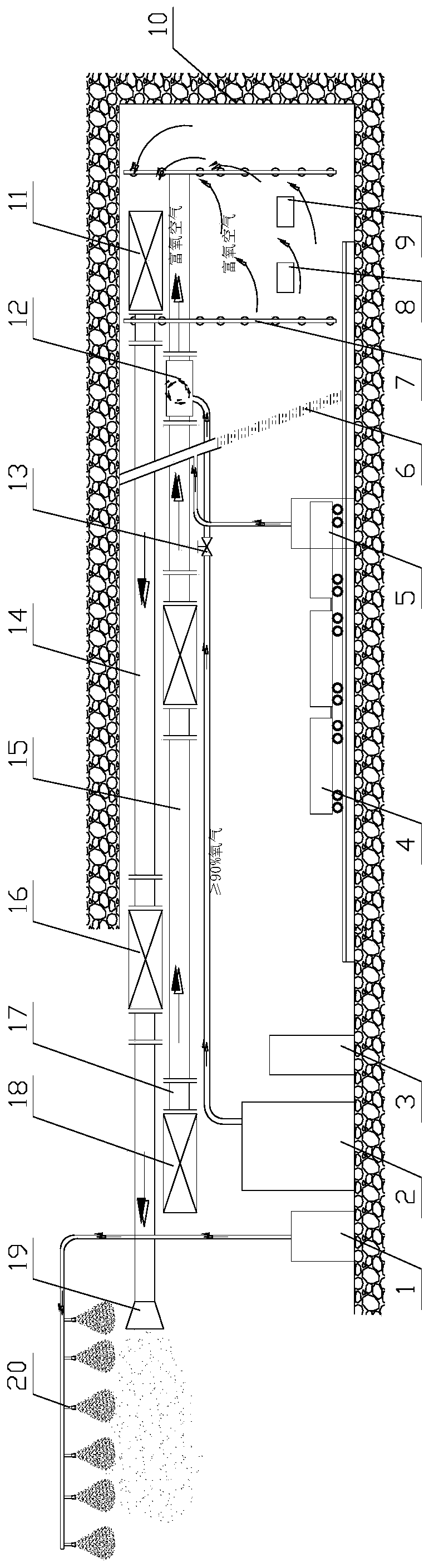

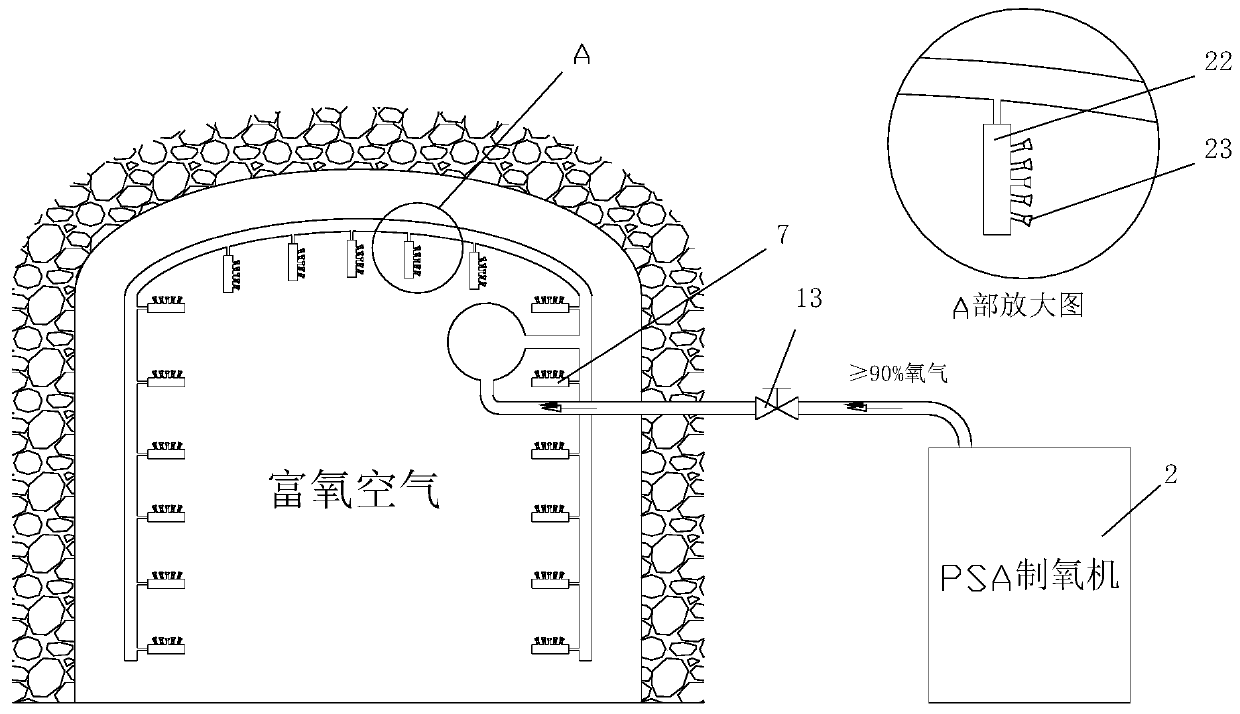

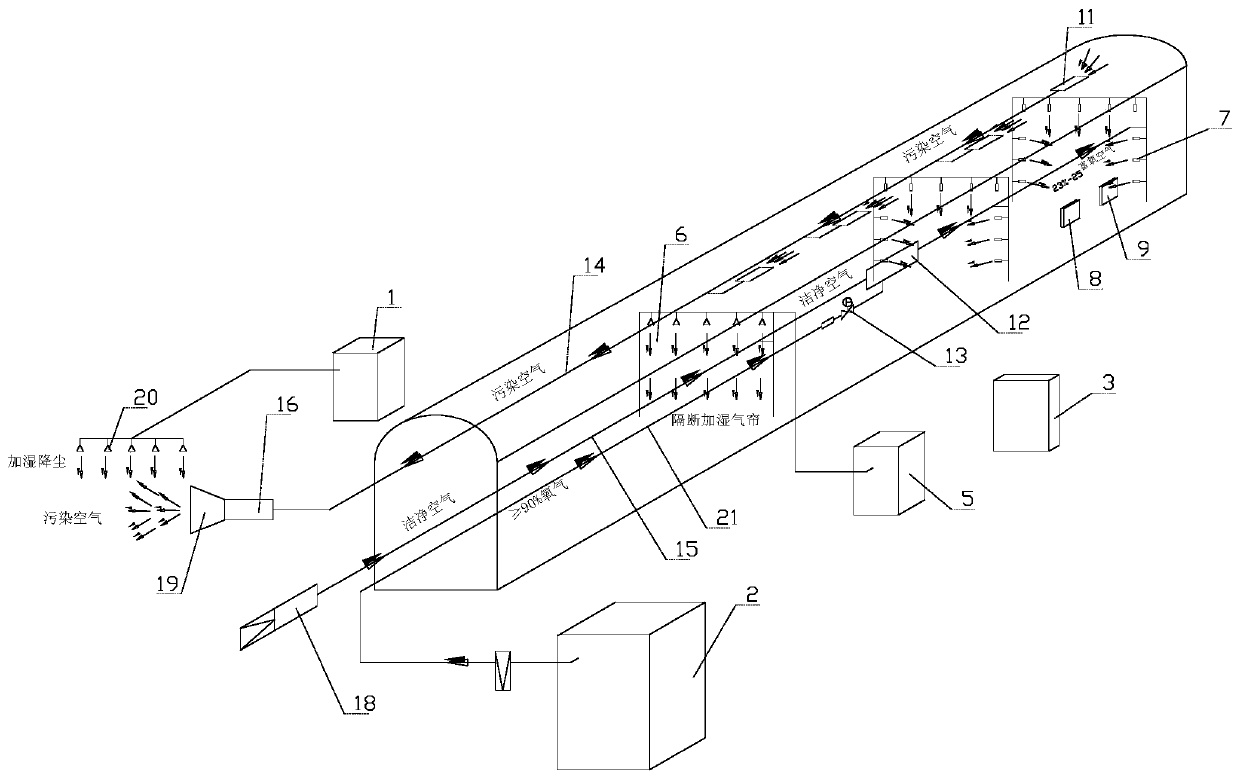

[0023] Such as figure 1 , figure 2 As shown, in the deep tunnel oxygen-enriched gas circulation system of the present invention, the construction transport vehicles 4 and personnel come to the tunnel face 10 to carry out digging work along the tunnel, and along the depth of the tunnel, fresh air pipes 15 and exhaust air Tube 14 is used to renew the air in the hole. The fresh air pipe 15 is connected with the fresh air blower 18 by the soft connection joint 17 of the blower fan, and one end in the exhaust pipe 14 tunnel is connected with the No. I exhaust fan 11, and an exhaust outlet diffuser 19 is installed at the tail of the tunnel. The top of the diffusion device 19 is provided with a humidifying and dust-reducing device 20; the humidifying and dust-reducing device 20 is driven by No. 1 humidifier 1 to work. In order to strengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com