Food processor safe to use

A food processing machine, a safe technology, applied in the field of food processing, can solve problems such as difficult to install anti-overflow electrodes, to avoid shaking and bursting, the best effect, and reduce installation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

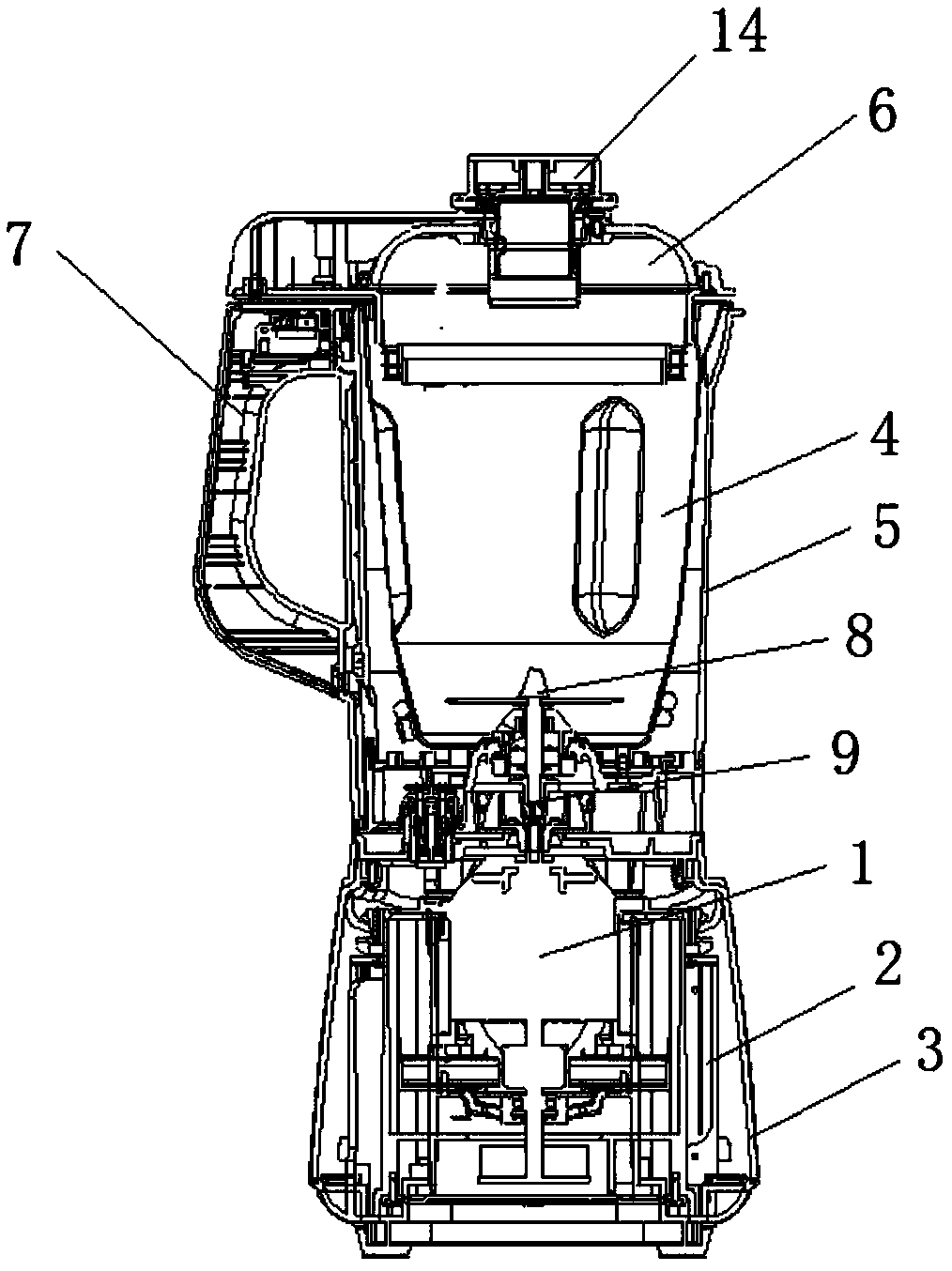

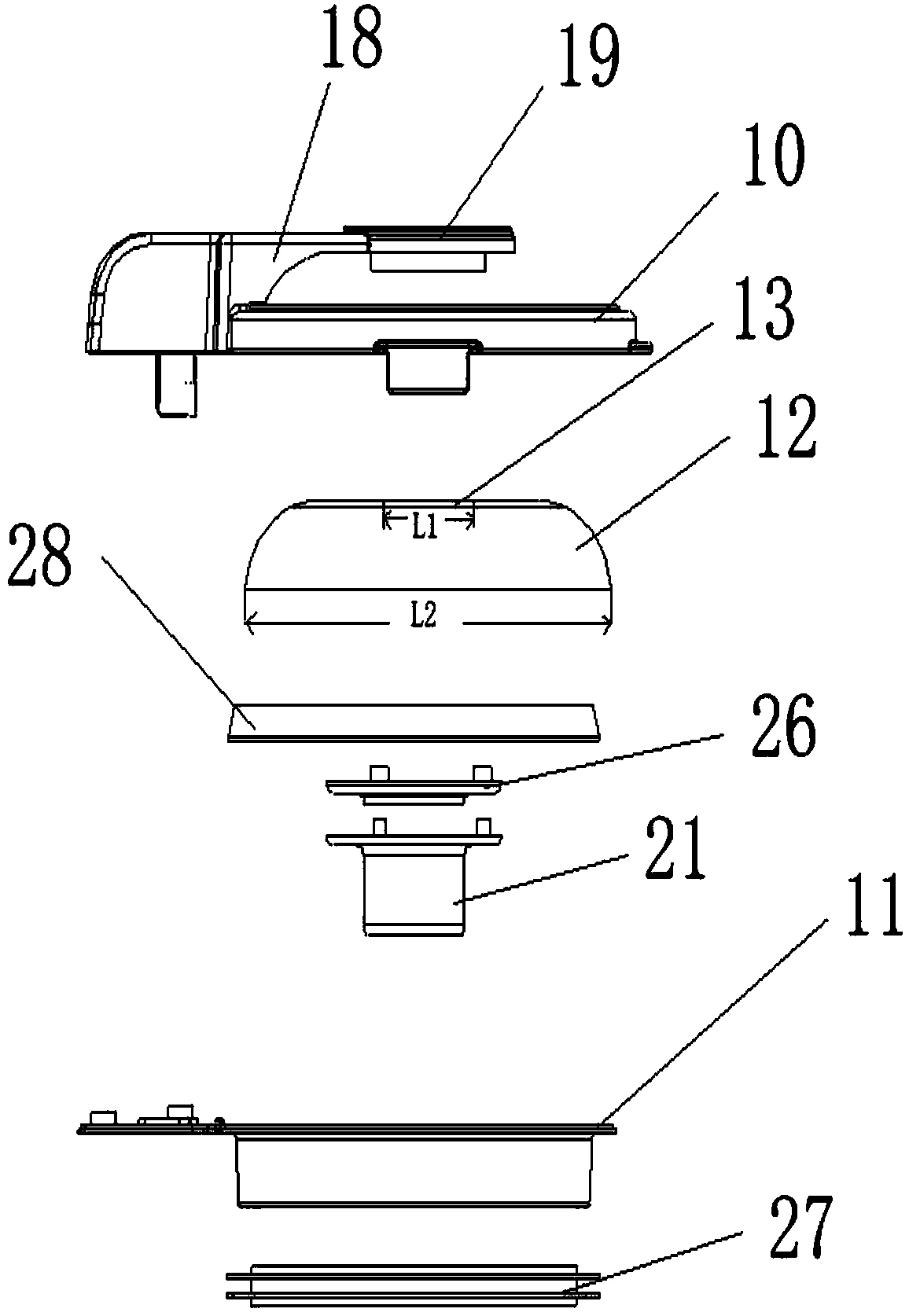

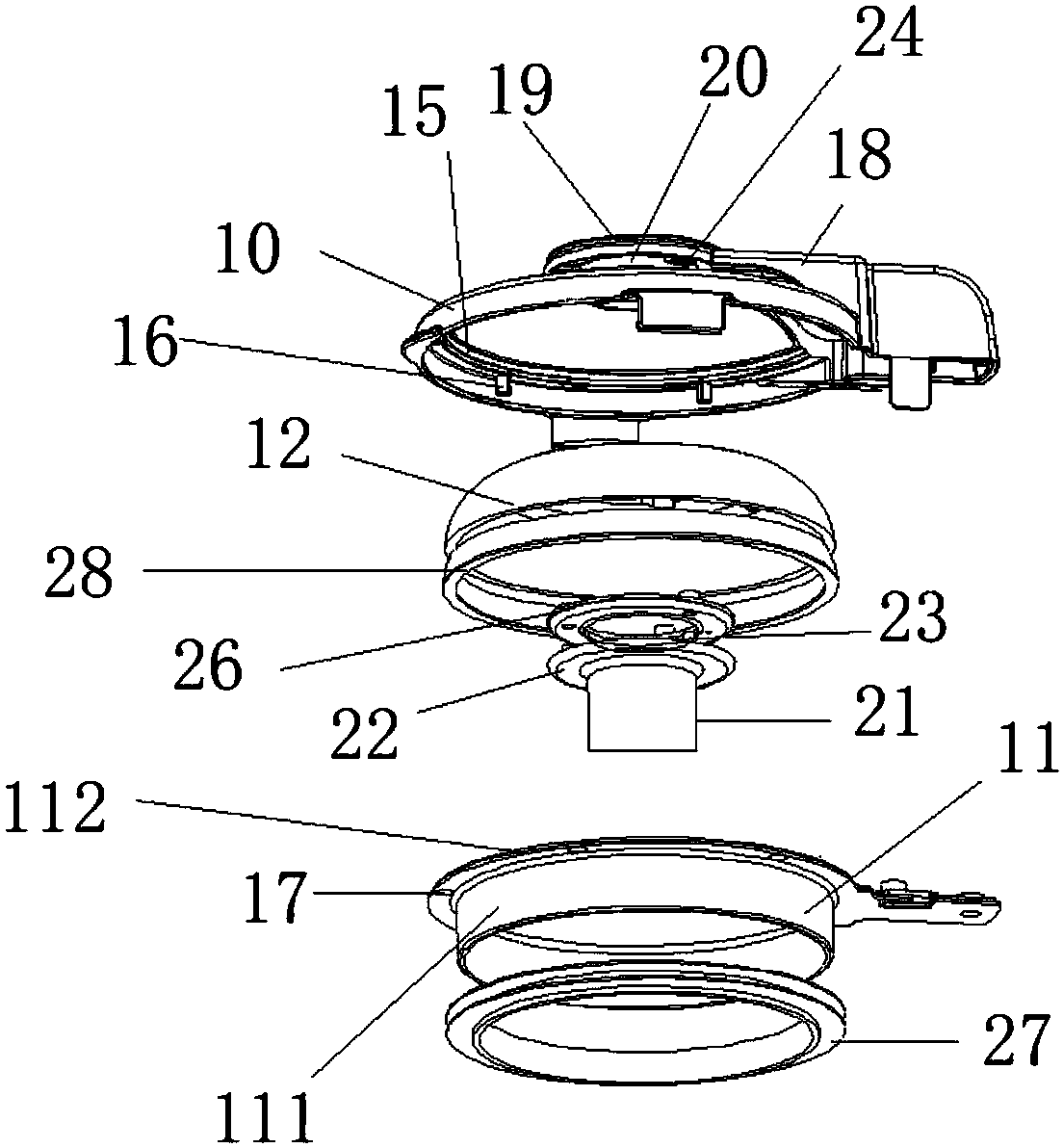

[0034] A safe food processing machine, in this embodiment, the food processing machine is a broken cooking machine, such as Figure 1-Figure 7 As shown, it includes a base 3 with a motor 1 and a main control board 2, the main control board 2 is electrically connected to the motor 1, and a stirring cup 4 is arranged on the base 3. The stirring cup 4 includes a cup body 5 and a cup cover 6, In this embodiment, the cup body 5 is a glass cup body 5, the cup cover 6 is closed and arranged above the cup body 5, the cup body 5 is provided with a handle 7, the cup body 5 is provided with a crushing knife 8, and the motor 1 passes through the upper and lower coupling shafts. The cooperation of the device 9 drives the pulverizer 8 to rotate. The cup cover 6 includes an annular upper bracket 10, an annular lower bracket 11 and a glass cover 12. The upper bracket 10 and the lower bracket 11 are made of plastic, and the glass cover 12 is set Between the upper bracket 10 and the lower brack...

Embodiment 2

[0054] The difference between this embodiment and Embodiment 1 is that in this embodiment, if Figure 8 As shown, the lower bracket 11 is a double-layer structure, including a plastic outer layer 113 and a stainless steel inner layer 114, the plastic outer layer 113 is sleeved outside the stainless steel inner layer 114, and the stainless steel inner layer 114 is in contact with the slurry to form the inner side wall of the cup cover 6 . Specifically, the installation flange of the plastic outer layer 113 is provided with a plastic screw hole 115, the installation flange of the stainless steel inner layer 114 is provided with a stainless steel gap 116, and the upper bracket 10 is provided with a downwardly arranged upper bracket threaded column 16. , the screws pass through the plastic screw holes sequentially from bottom to top, and are fixedly installed with the upper bracket threaded column 16 after the stainless steel notch, because the outer edge of the glass cover 12 is ...

Embodiment 3

[0056] The difference between this embodiment and Embodiment 1 is that in this embodiment, if Figure 9 and Figure 10 As shown, the food processor also includes a heating device, which can make hot drinks. This embodiment is a heating plate arranged at the lower end of the stirring cup 4. The heating plate belongs to the prior art and will not be described in detail in this application. The cup cover 6 also includes an anti-overflow electrode 29, one end of the anti-overflow electrode 29 is installed on the glass cover 12, the installation mentioned here refers to the installation relationship with the glass cover 12, the specific form is not limited, it can be installed directly or It is an indirect installation, the other end of the anti-overflow electrode 29 is set downward, and the anti-overflow electrode 29 is electrically connected to the main control board 2 through a conductive structure. This arrangement ensures that the anti-overflow electrode 29 can also be provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com