Manual hole digging pile concrete precast retaining wall and construction method thereof

A technology of manual excavation of piles and concrete, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., and can solve problems such as failure to fundamentally prevent soil wall collapse, long construction period, and difficulty in ensuring the quality of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

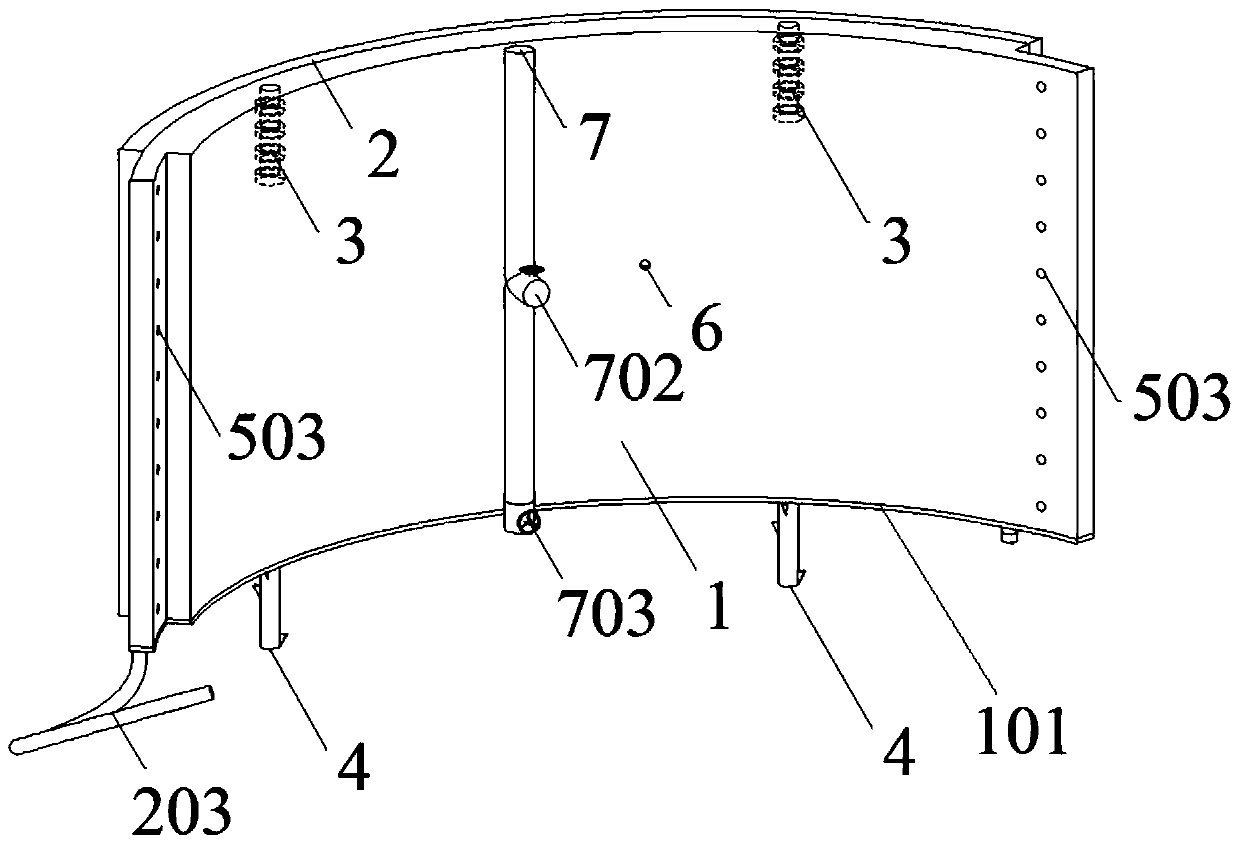

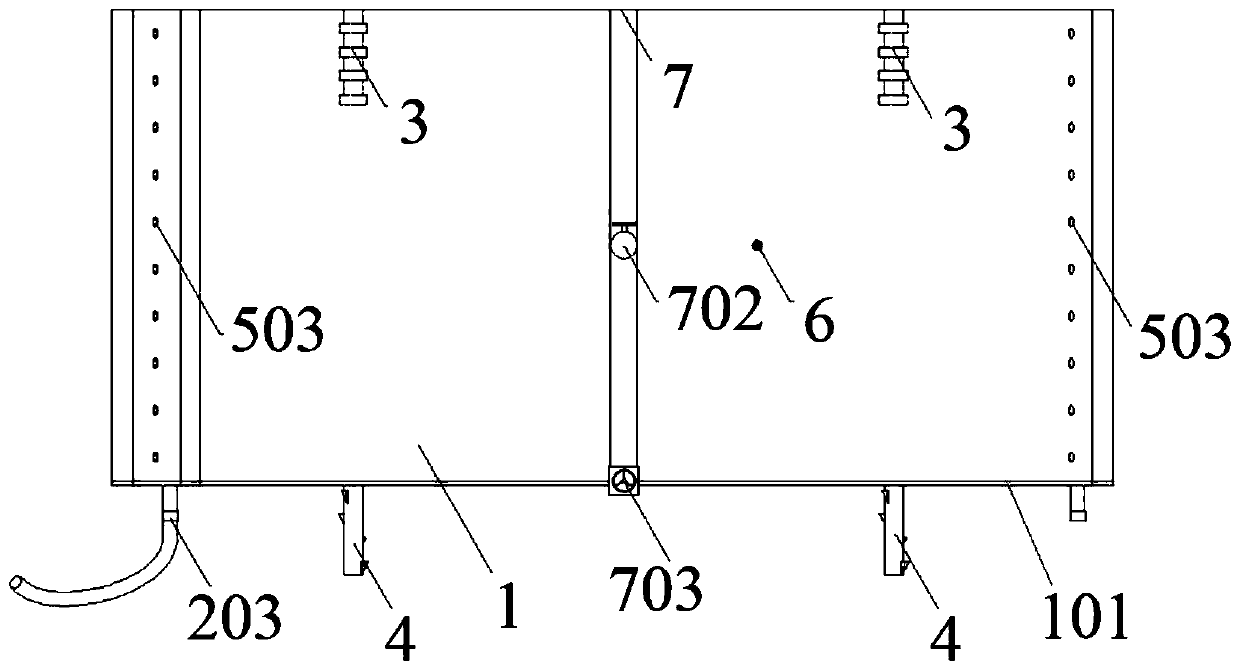

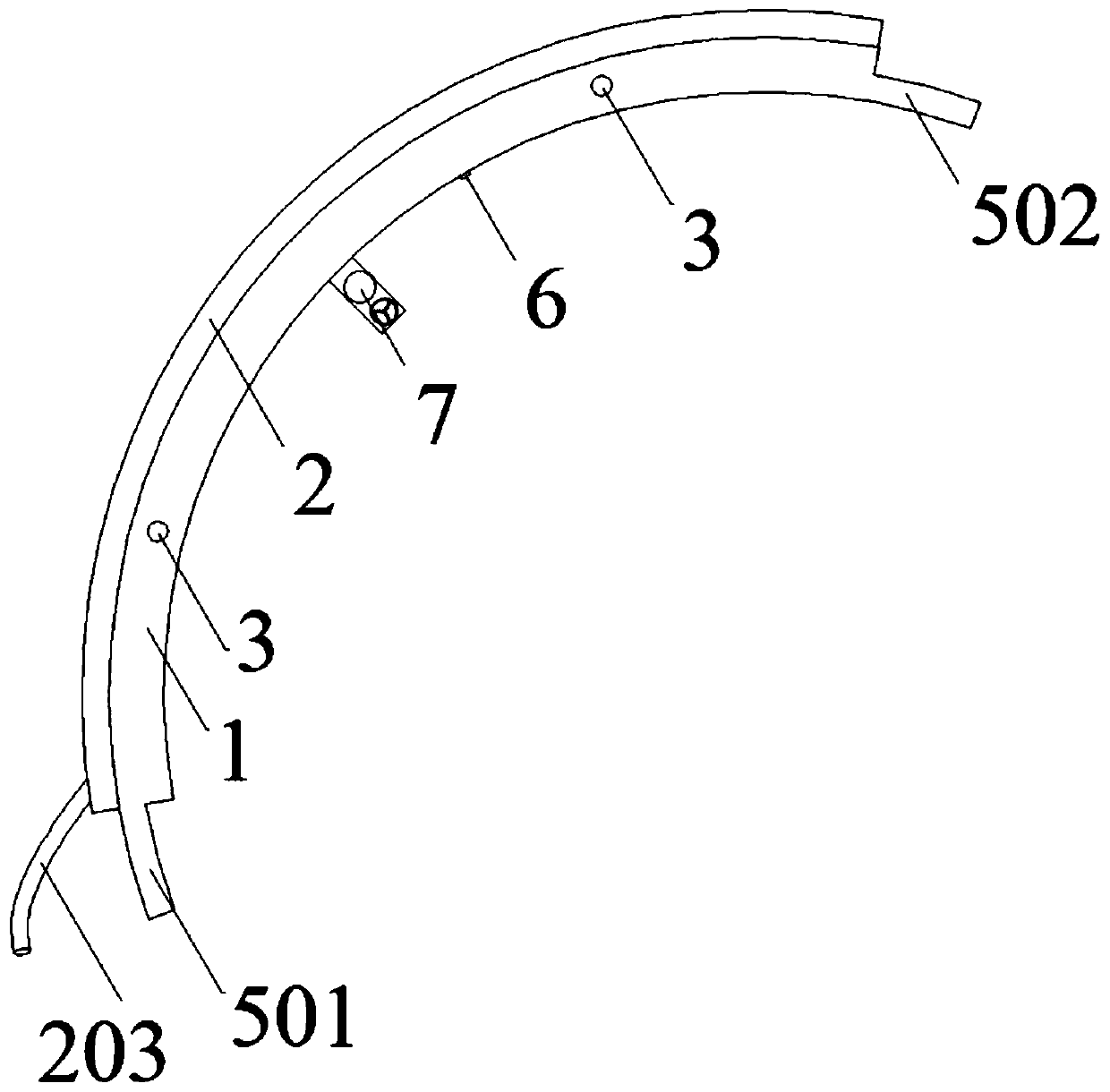

[0173] A concrete prefabricated retaining wall of manual digging piles, the prefabricated retaining wall comprises: a retaining wall main body 1 and an elastic structure layer 2 . The retaining wall main body 1 is connected end to end to form a complete concrete retaining wall. The elastic structure layer 2 is arranged on the outer side of the wall main body 1 .

Embodiment 2

[0175] Example 1 is repeated, except that the elastic structural layer 2 includes: a capsule block 201 , and a medium inlet and outlet 202 . The inside of the capsule block 201 communicates with the outside through the medium inlet and outlet 202 . The capsule block 201 is disposed on the outside of the wall main body 1 .

Embodiment 3

[0177] Embodiment 2 is repeated, except that the elastic structural layer 2 further includes: a balancing duct 203 . The capsule blocks 201 between adjacent retaining walls are communicated through a balancing pipe 203 . The prefabricated retaining wall also includes: a water-stop pad 101 . The water-stop pad 101 is arranged on the upper end surface of the main wall main body 1 , and / or the water-stop pad 101 is arranged on the lower end surface of the main wall main body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com